Vehicle energy management method for electric vehicle power system, and vehicle

A vehicle energy management and power system technology, which is applied to the vehicle energy management method of the electric vehicle power system and the vehicle field, can solve the problems of power battery life attenuation, system temperature rise, inability to meet user needs, etc., and achieve extended use. Longevity, guaranteed dynamism and economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

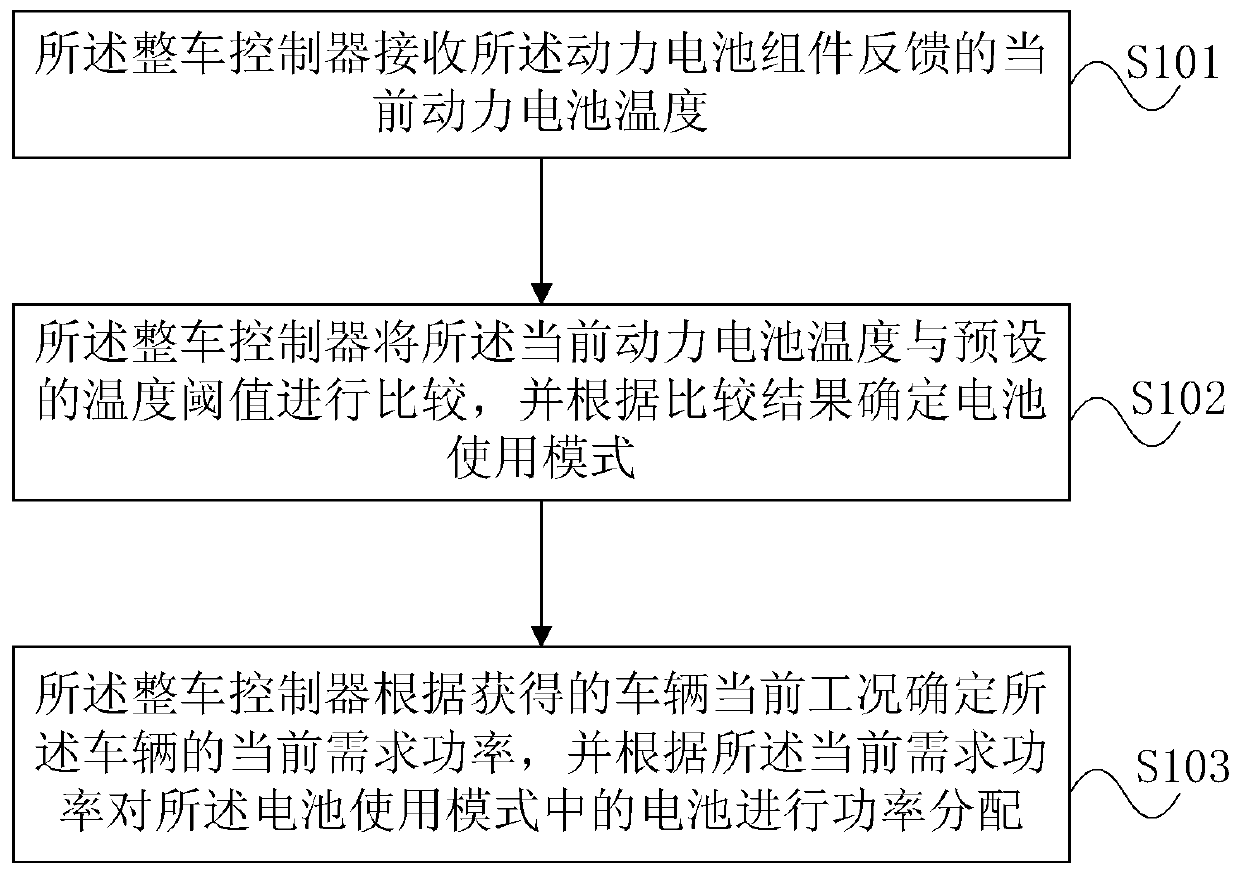

[0053] figure 1 It is a schematic flowchart of a vehicle energy management method for an electric vehicle power system provided by Embodiment 1 of the present invention. This embodiment is applicable to electric vehicles using a composite power supply scheme of a flywheel battery and a power battery, and the battery is selected based on the temperature of the power battery. mode, so as to realize the situation of vehicle energy management; this method can be executed by the vehicle controller, and the vehicle controller can be realized by hardware and / or software, and generally integrated in the electric vehicle applying the vehicle energy management method on the car.

[0054] It is understandable that due to the influence of electrochemical characteristics, lithium-ion and other power batteries cannot achieve short-term high-power electric energy output or input, and extreme working conditions such as low-temperature environment or high-temperature environment will aggravate...

Embodiment 2

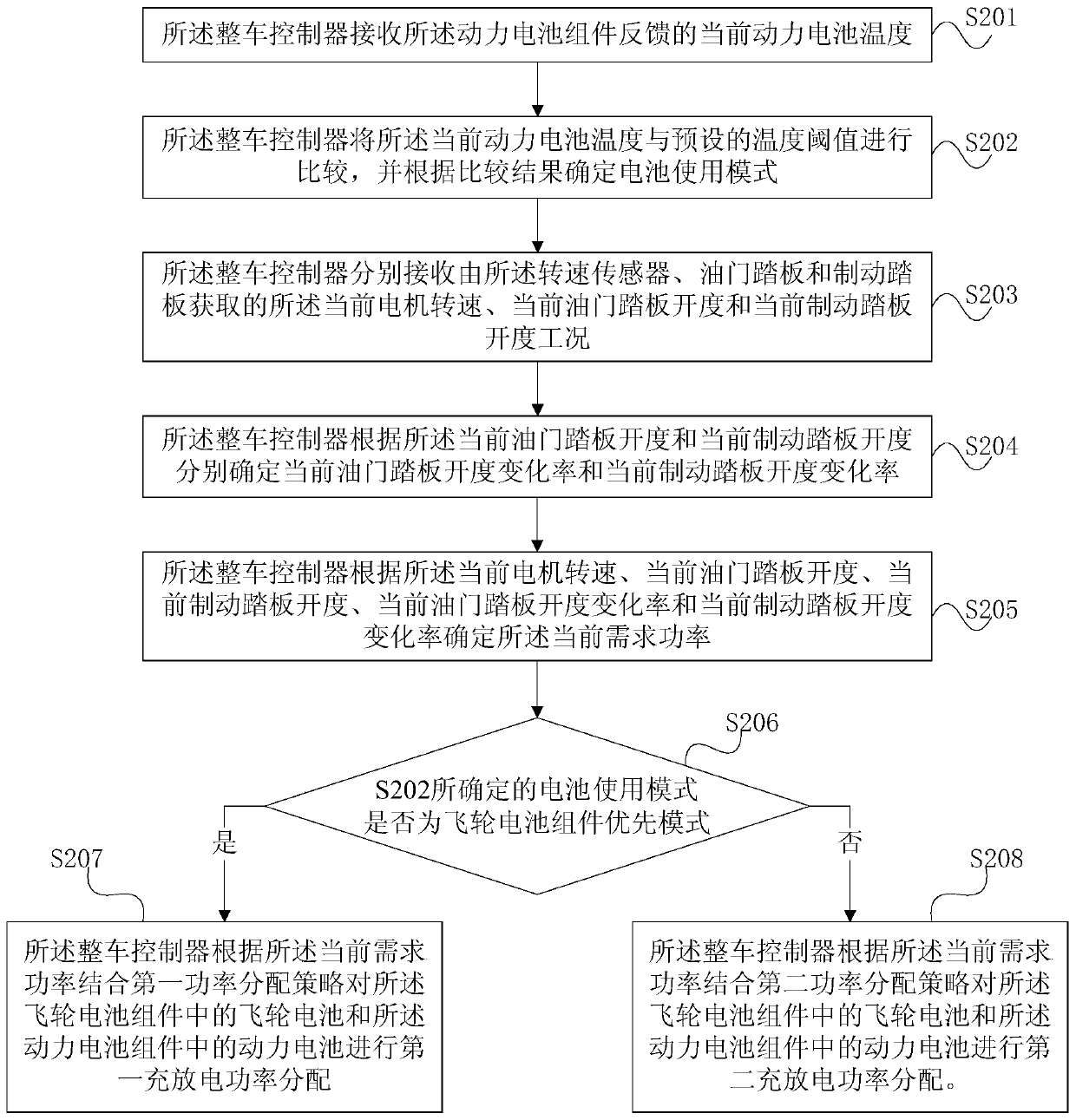

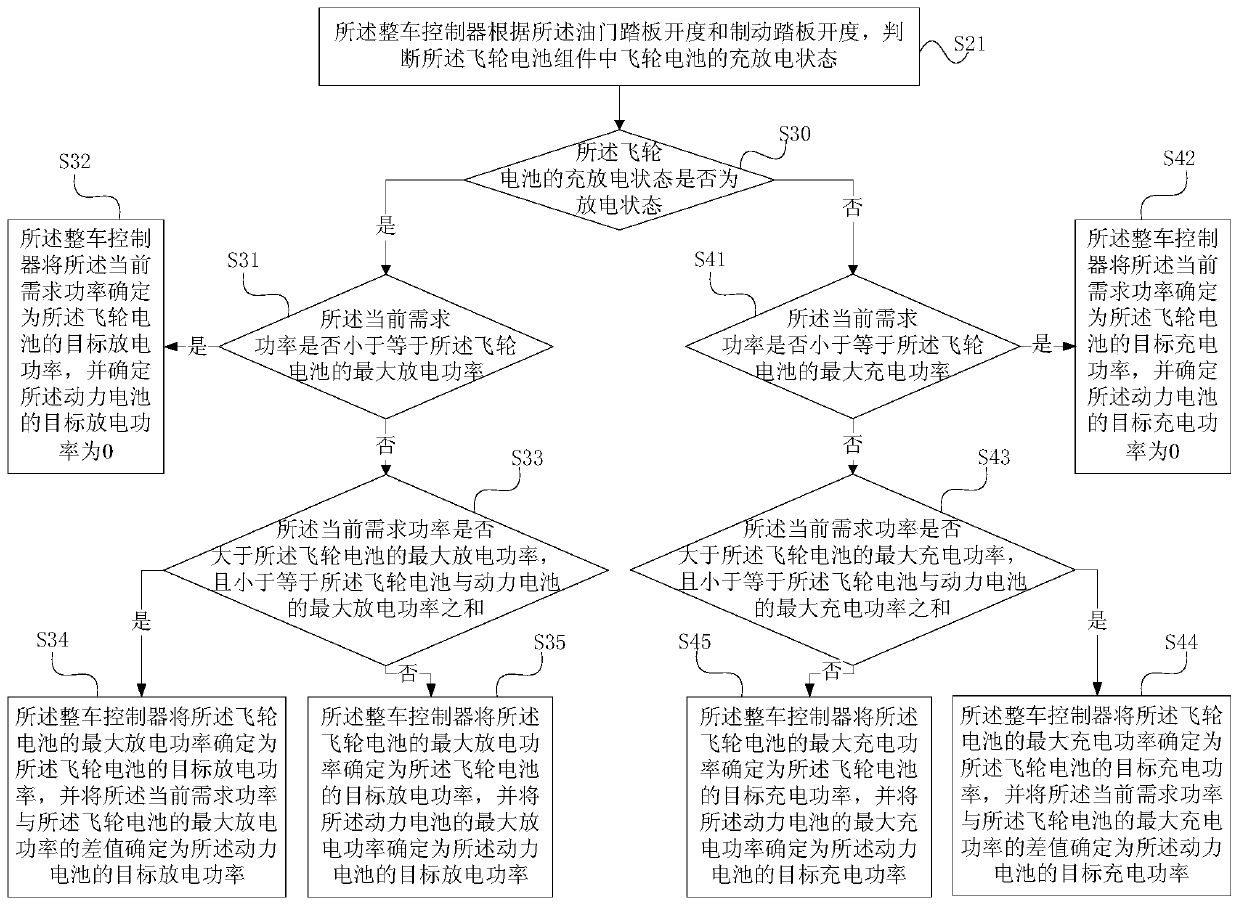

[0094] figure 2 It is a schematic flowchart of a vehicle energy management method for a power system of an electric vehicle provided in Embodiment 2 of the present invention. This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the vehicle controller allocates power to the battery in the battery usage mode according to the current demand power, and the specific optimization is: when the battery usage mode is the flywheel battery assembly priority mode, the The car controller performs the first charging and discharging power distribution on the flywheel battery in the flywheel battery assembly and the power battery in the power battery assembly according to the current demand power combined with the first power distribution strategy; when the battery usage mode is In the power battery assembly priority mode, the vehicle controller performs a second charge and discharge on the flywheel battery in the flywheel battery assembly and the power batt...

Embodiment 3

[0170] Figure 5 It is a schematic structural diagram of a vehicle provided by Embodiment 3 of the present invention. Such as Figure 5 As shown, the vehicle includes: a vehicle controller 301 , a flywheel battery assembly 302 , a power battery assembly 303 , an accelerator pedal 304 , a brake pedal 305 , a charging assembly 306 , a motor assembly 307 and a memory 308 .

[0171] Among them, the vehicle controller 301 is respectively connected with the flywheel battery assembly 302, the power battery assembly 303, the accelerator pedal 304, the brake pedal 305, the charging assembly 306, the motor assembly 307 and the memory 308, and is used to collect the working conditions of other components. , and send corresponding control commands to other components according to the working conditions, so as to complete the management and distribution of vehicle energy.

[0172] The flywheel battery assembly 302 is connected to the vehicle controller 301 and the motor assembly 307 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com