Resistance recovery energy-saving ship

A resistance and hydraulic technology, applied in the field of resistance recovery and energy-saving ships, can solve the problems of cumbersome circuit energization system, reduced safety and reliability, reduced navigation stability, etc., and achieves increased stern propulsion capacity, fast capital return, and significant energy saving and environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

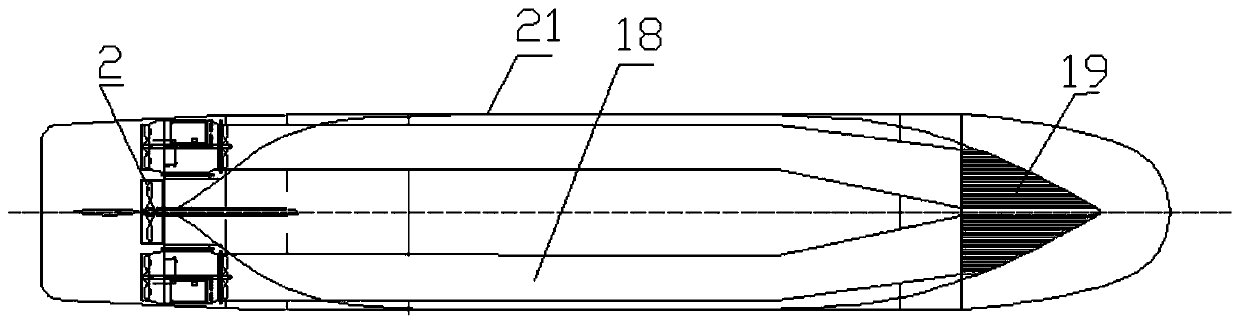

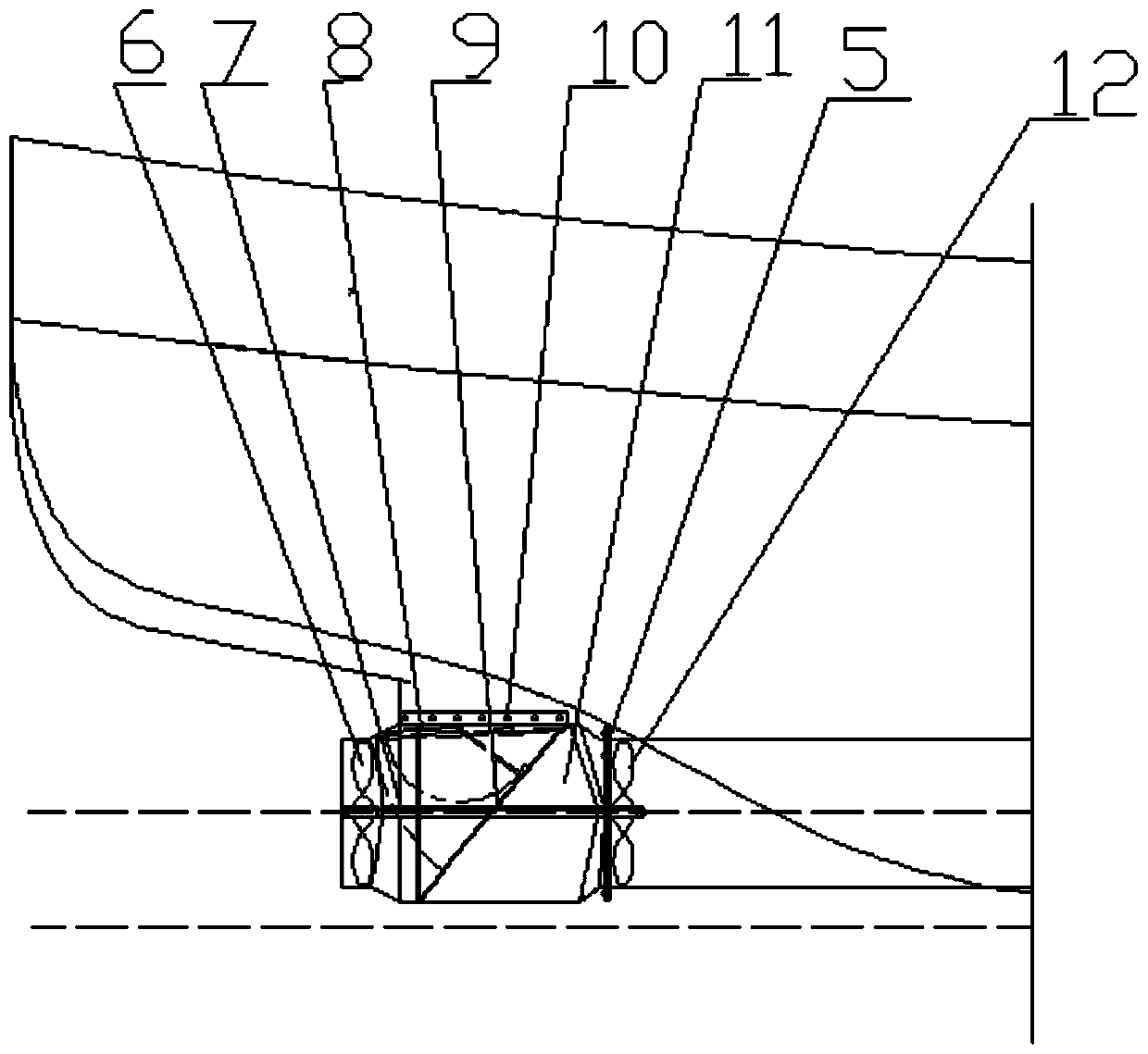

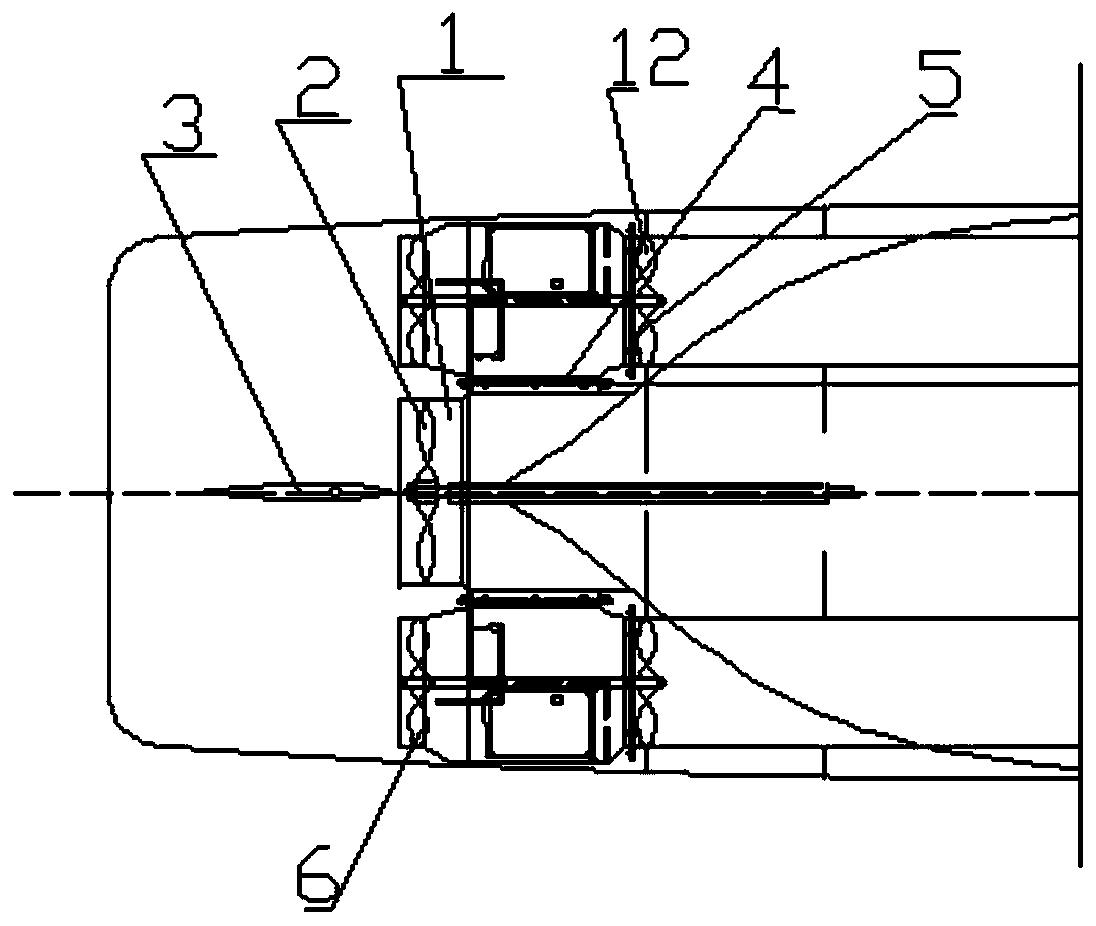

[0026] Such as Figure 1-6 As shown, a resistance recovery energy-saving ship includes a hull 21, a hydraulic converter 11, and a water turbine 12. A waterway 18 is arranged below the empty waterline in the hull 21, and one end of the waterway 18 is passed through the No. 1 method. The flange 4 is provided with a hydraulic converter 11, and the other end of the hydraulic converter 11 is connected to the No. 2 flange 5 of the propeller water supply port 17 of the main engine. One end of the shaft 7 is equipped with a water turbine 12 through a bolt, the other end of the water turbine connecting shaft 7 is installed with a negative machine propeller 6 through a bolt, and one end of the water turbine 12 is provided with a negative machine propeller water supply port 13, the hydraulic conversion The middle part of the device 11 is installed with a hydraulic converter internal isolation plate 16 through the mounting bracket, and one end of the water supply port 13 of the negative e...

Embodiment 2

[0037] Such as Figure 1-6 As shown, a resistance recovery energy-saving ship includes a hull 21, a hydraulic converter 11, and a water turbine 12. A waterway 18 is arranged below the empty waterline in the hull 21, and one end of the waterway 18 is passed through the No. 1 method. The flange 4 is provided with a hydraulic converter 11, and the other end of the hydraulic converter 11 is connected to the No. 2 flange 5 of the propeller water supply port 17 of the main engine. One end of the shaft 7 is equipped with a water turbine 12 through a bolt, the other end of the water turbine connecting shaft 7 is installed with a negative machine propeller 6 through a bolt, and one end of the water turbine 12 is provided with a negative machine propeller water supply port 13, the hydraulic conversion The middle part of the device 11 is installed with a hydraulic converter internal isolation plate 16 through the mounting bracket, and one end of the water supply port 13 of the negative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com