Ozone electrolysis structure and electrolysis chamber

An electrolysis chamber and ozone technology, applied in the direction of electrolysis process, electrolysis components, electrode shape/type, etc., can solve the problems of easy scale accumulation on the electrode surface and low ozone production efficiency, so as to improve ozone production efficiency and reduce electrolysis energy consumption , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

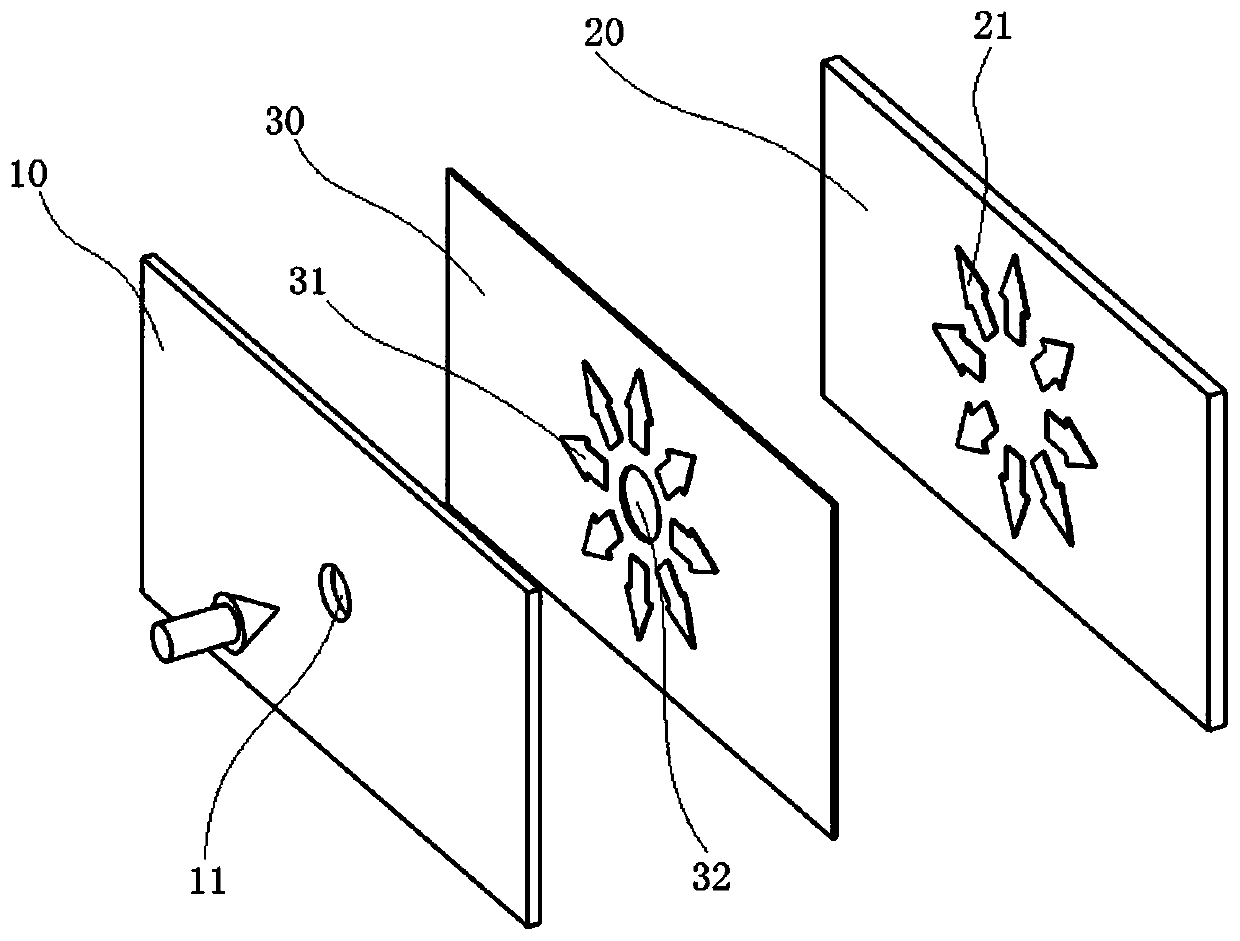

[0042] Please refer to figure 1 , figure 1 One of the ozone electrolysis structures is Embodiment 1 of the present invention, comprising an anode sheet 10 and a cathode sheet 20 arranged at intervals, the anode sheet 10 is located at the water inlet end, the cathode sheet 20 is located at the water outlet end, and the anode sheet A main proton exchange membrane 30 is provided between 10 and the cathode sheet 20;

[0043] The anode sheet 10 is provided with a water inlet hole 11 , the main proton exchange membrane 30 is provided with a water passage hole 32 , and the cathode sheet 20 is provided with a convex structure or a concave structure 21 on the side of the water inlet side.

[0044]As can be seen from the above, when in use, the ozone electrolysis structure of the present invention is set in the electrolysis chamber, and when the water body is electrolyzed, after the water body between the anode sheet and the main proton exchange membrane is initially electrolyzed by th...

Embodiment 2

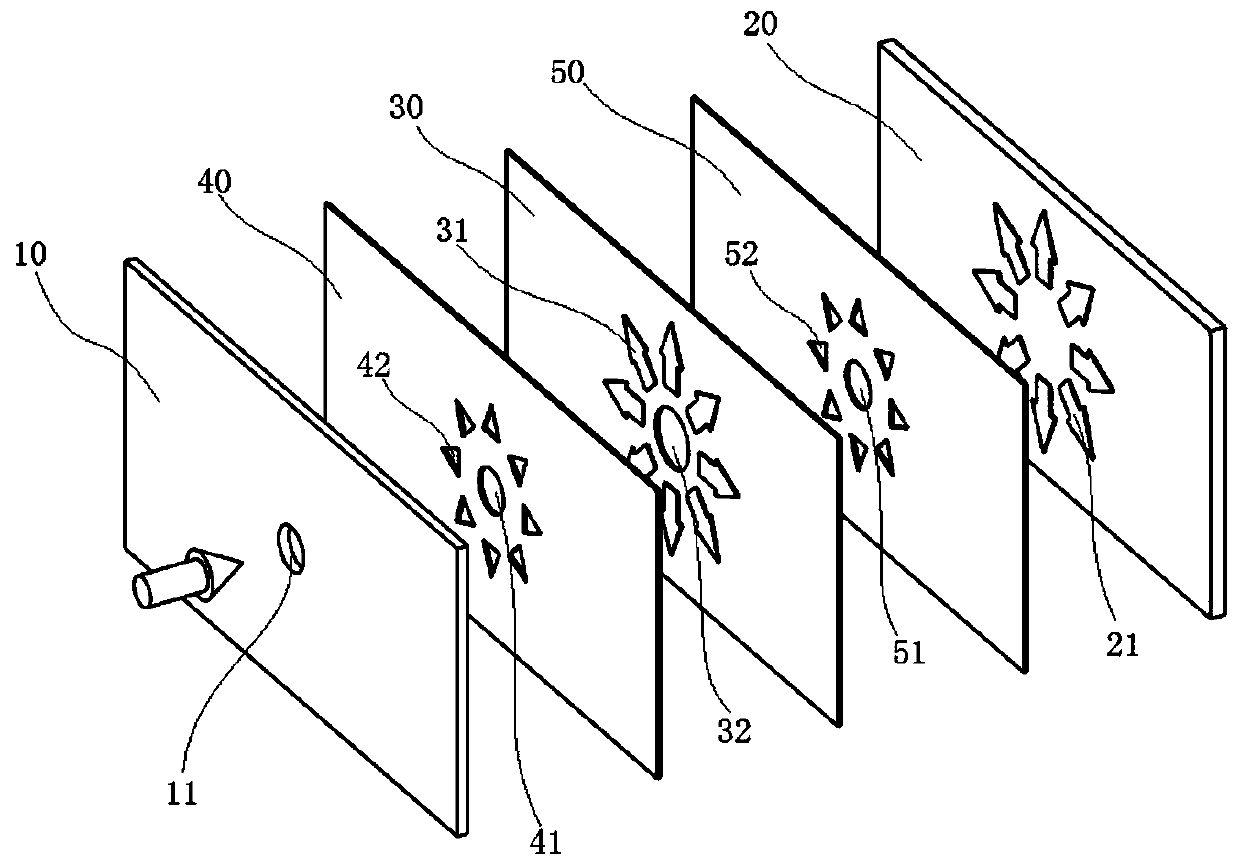

[0058] Please refer to figure 2 , figure 2 A kind of ozone electrolysis structure in is embodiment 2 of the present invention, and present embodiment is on the basis of embodiment 1, makes following improvement again:

[0059] Wherein, at least one layer of first auxiliary proton exchange membrane 40 is arranged between the anode piece 10 and the main proton exchange membrane 30, and the first auxiliary proton exchange membrane 40 is provided with flow guide holes 41, and the first The auxiliary proton exchange membrane 40 is provided with several diversion holes 42 around the diversion hole 41, and the plurality of diversion holes 42 are evenly distributed along the same circle with the center of the diversion hole 41 as the center.

[0060] Wherein, at least one layer of second auxiliary proton exchange membrane 50 is arranged between the cathode sheet 20 and the main proton exchange membrane 30, and the second auxiliary proton exchange membrane 50 is provided with flow g...

Embodiment 3

[0067] This embodiment discloses an ozone electrolysis chamber, which includes a body of the electrolysis chamber. The body of the electrolysis chamber is provided with a water inlet and a water outlet. The body of the electrolysis chamber is provided with the ozone electrolysis structure described in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com