Crease-removing environment-friendly chemical-resistant fiber textile printing and dyeing machine

A chemical fiber, environmentally friendly technology, applied in the field of textiles, can solve the problems of reduced dyeing efficiency of fabrics, inconvenient fabric dyeing, etc., and achieve excellent drying effect, good smoothing effect, and the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

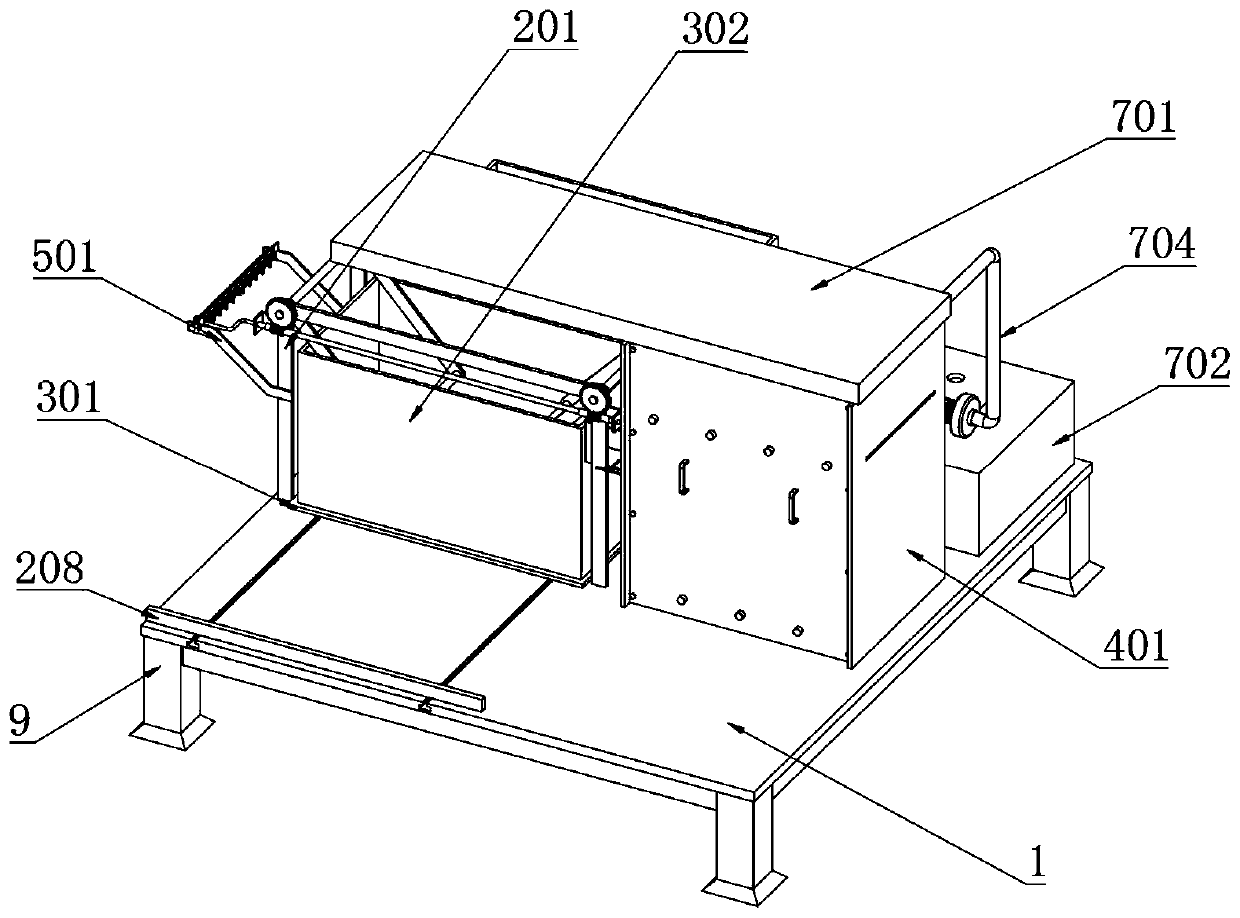

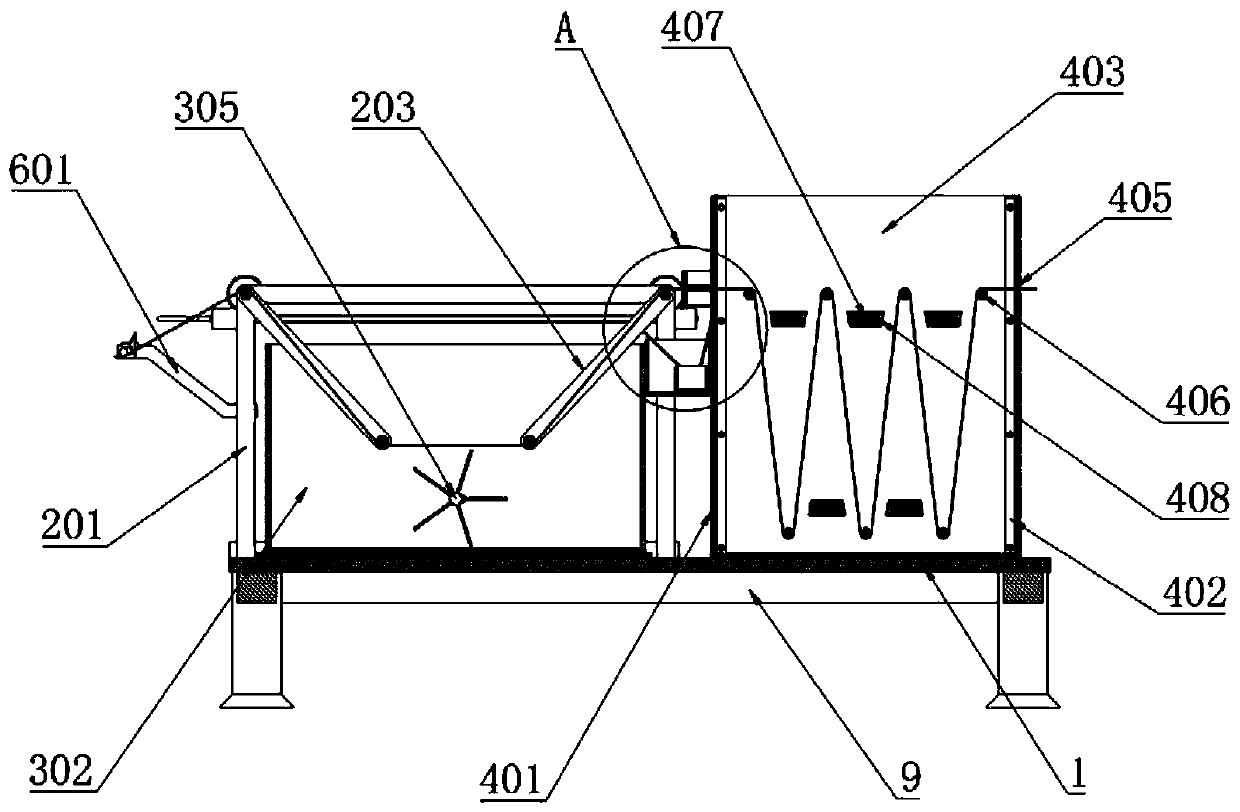

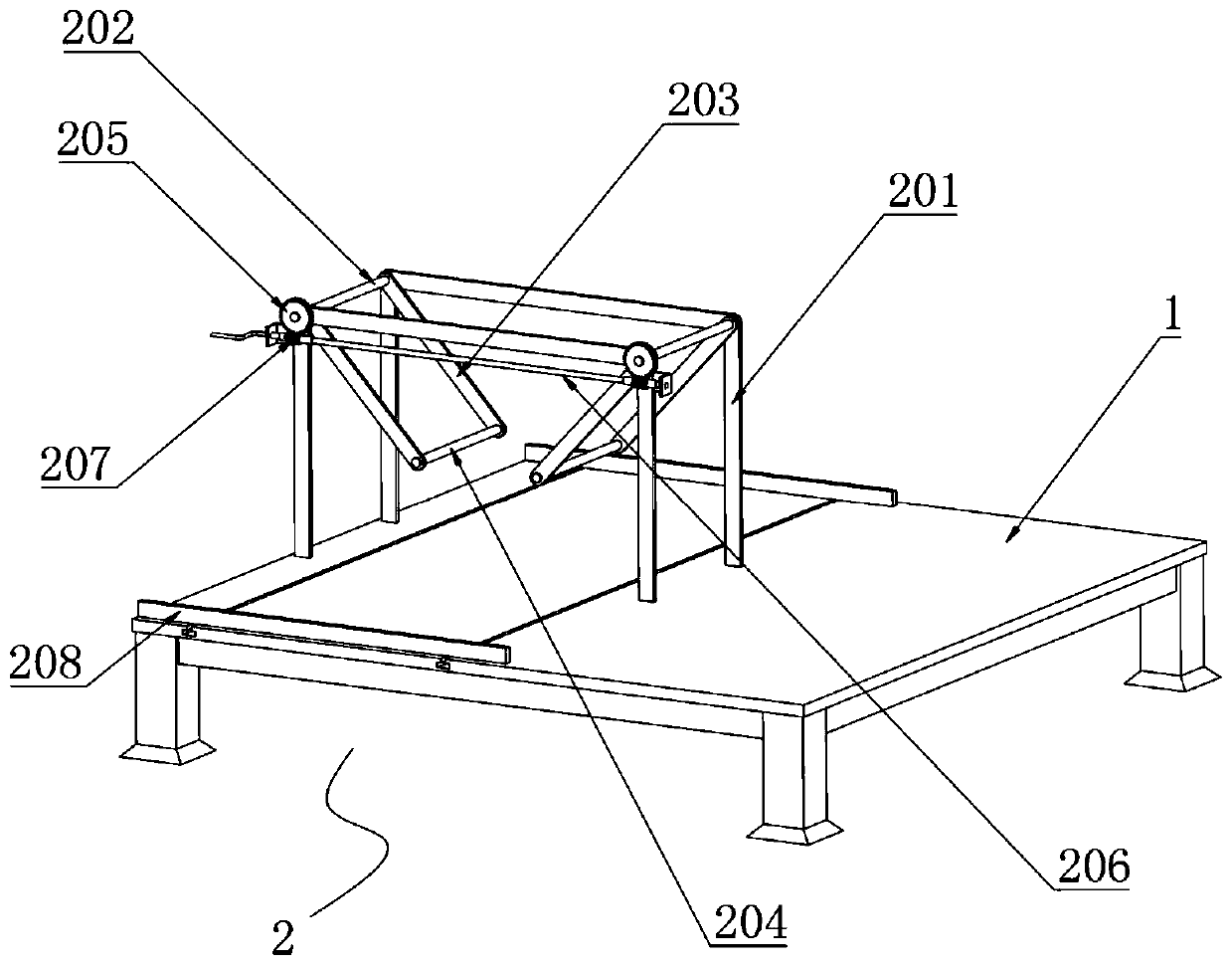

[0052] Example: such as Figure 1-13 As shown, the present invention provides a technical solution, a wrinkle-removing environmentally friendly chemical fiber textile printing and dyeing machine, including a workbench 1 and a frame 9, the top of the workbench 1 is installed on the top of the frame 9, and the top of the workbench 1 An adjustment assembly 2 is installed on one side, and the adjustment assembly 2 includes a mounting frame 201, an adjustment shaft 202, a linkage side plate 203, a lower pressure shaft 204, a worm wheel 205, a power shaft 206 and a worm sleeve 207;

[0053] A mounting frame 201 is symmetrically welded in the middle of the top of the workbench 1, and adjustment shafts 202 are rotatably connected to the top corners of the two mounting frames 201. One end of the two linkage side plates 203 on the side is welded with a lower pressure shaft 204, one end of the two adjustment shafts 202 is sleeved with a worm wheel 205, a power shaft 206 is installed on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com