Near-shore water surface garbage can

A technology of trash cans and barrels, applied in the field of water trash cans, can solve the problems of re-floating and the inability of the pump to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

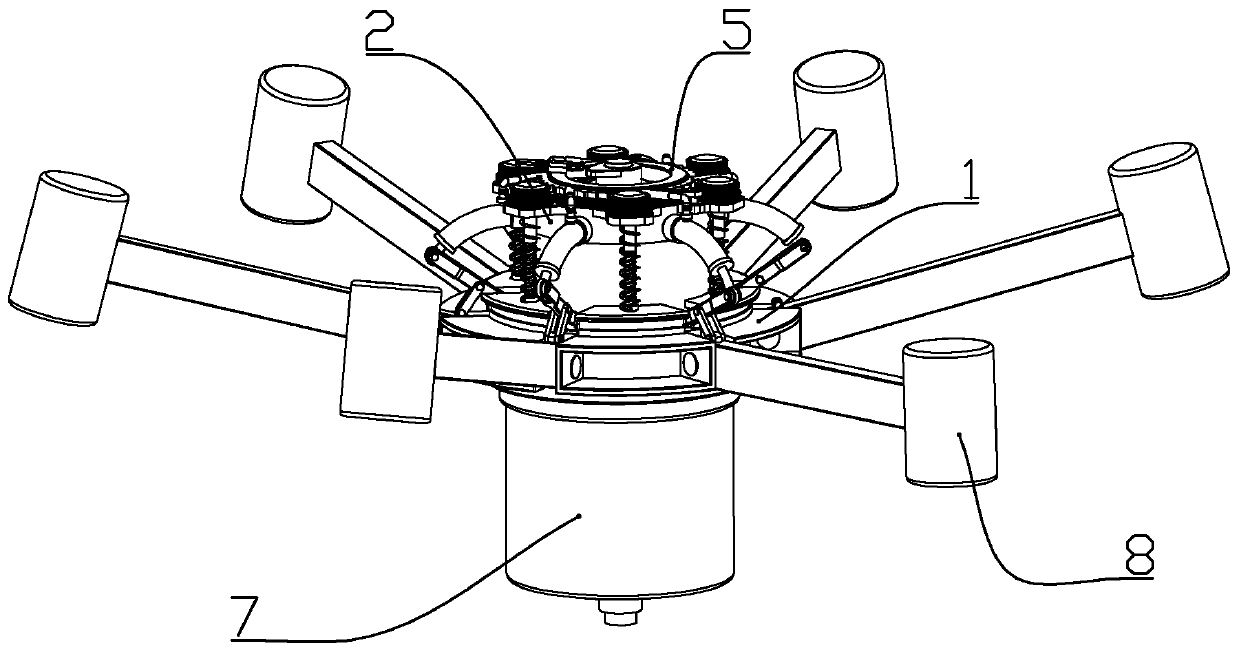

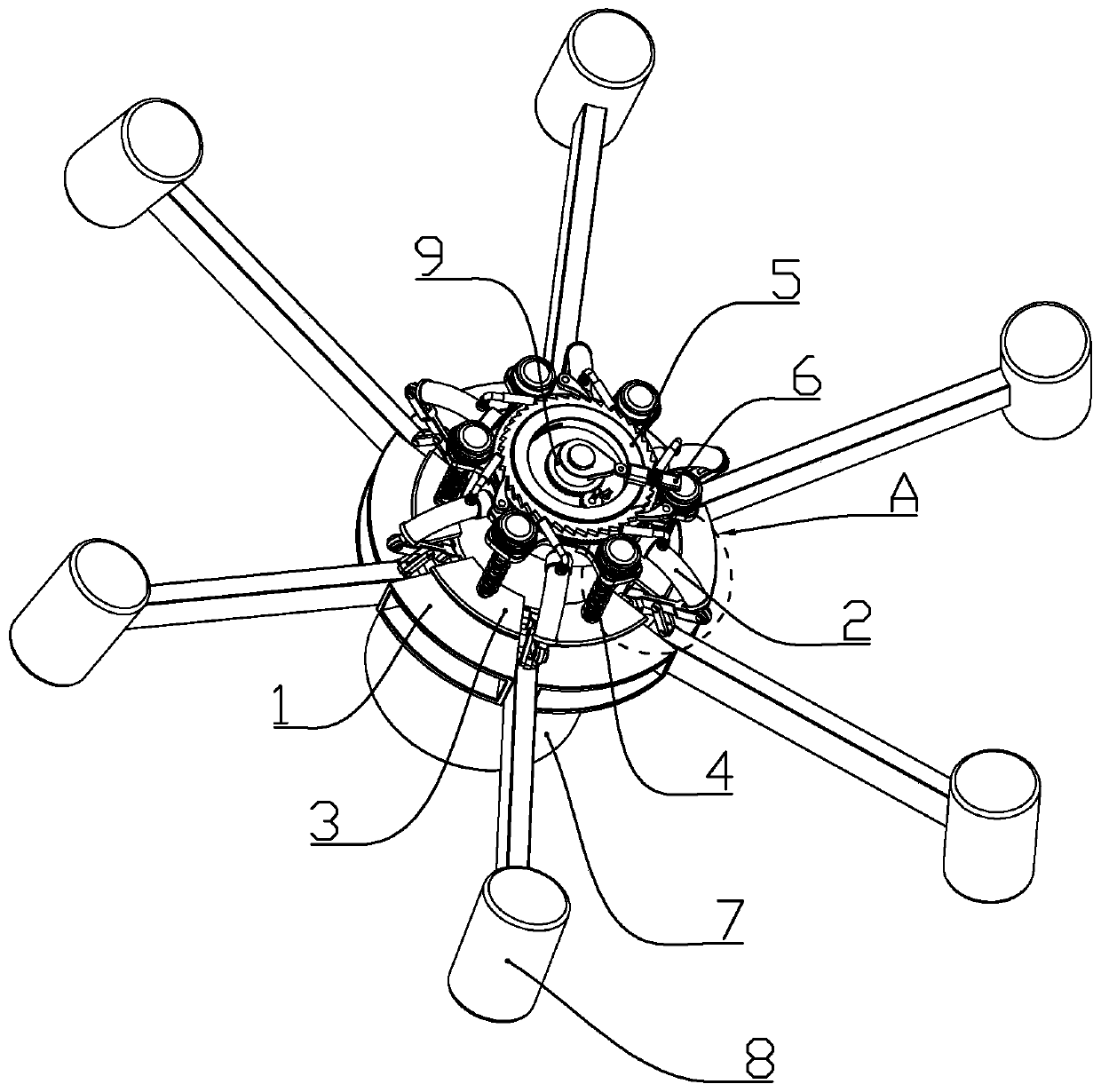

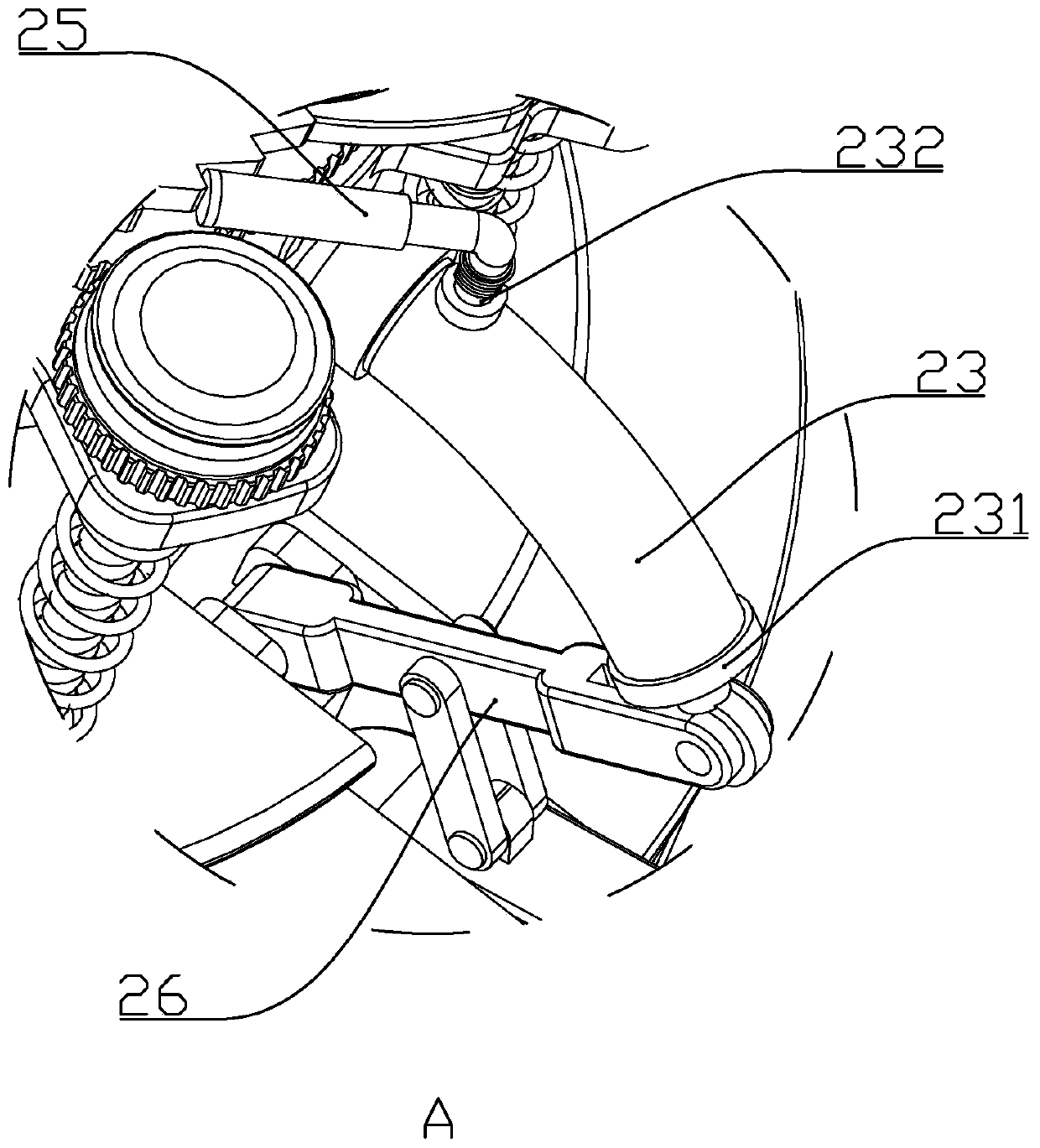

[0044] according to Figure 1 to Figure 19 As shown, a nearshore water surface trash can described in this embodiment includes a connecting body 1, a piston assembly 2 that is sealed and fixedly connected to the upper end of the connecting body 1, and a piston assembly 2 that is detachably and sealingly connected to the lower end of the connecting body 1. The barrel body 7, the sealing plate 3 inserted on the connecting body 1 for sealing, the gear assembly 5 connected to the upper end of the piston assembly 2 for unidirectional rotation, is slidably connected with the blocking plate 3 and connected with the gear The assembly 5 is meshed with the transmission assembly 4 connected by transmission, the positioning rotation cam 9 installed on the upper end of the piston assembly 2 , and the guide rod 6 horizontally slidably connected to the upper end of the gear assembly 5 to abut against the positioning rotation cam 9 .

[0045] The piston assembly 2 includes a connection cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com