Pipe gallery protection prestressed beam and its construction method

A technology of prestressed beams and construction methods, applied in protection devices, artificial islands, water conservancy projects, etc., can solve the problems of total construction period, cost and resource increase, urban residents' work and life impact, long time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

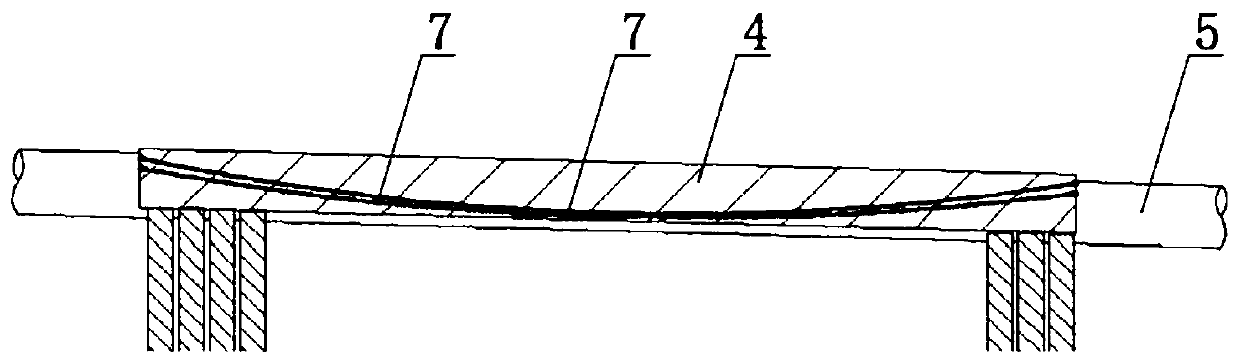

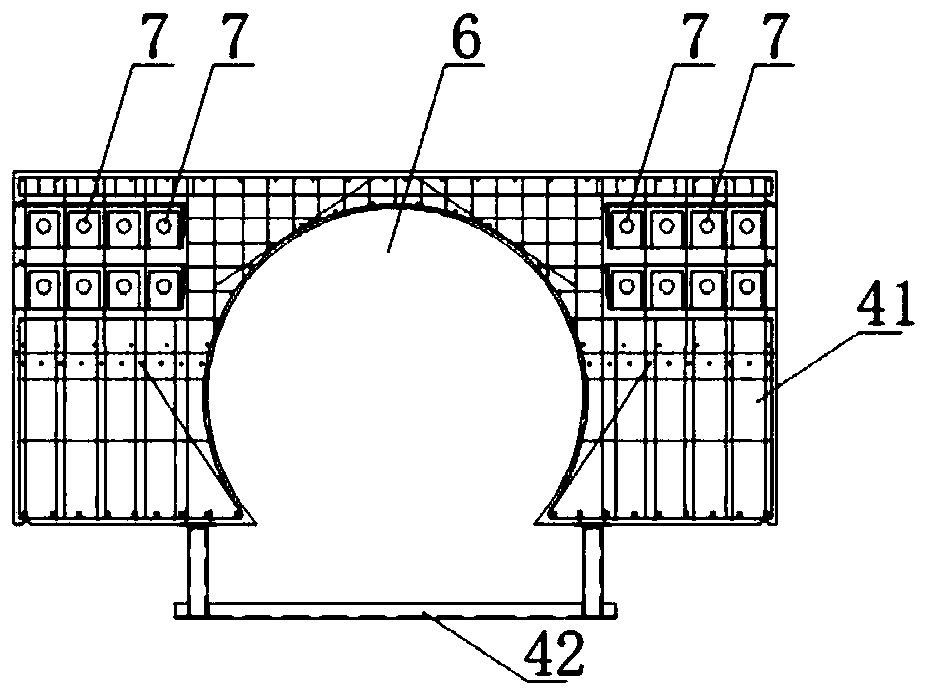

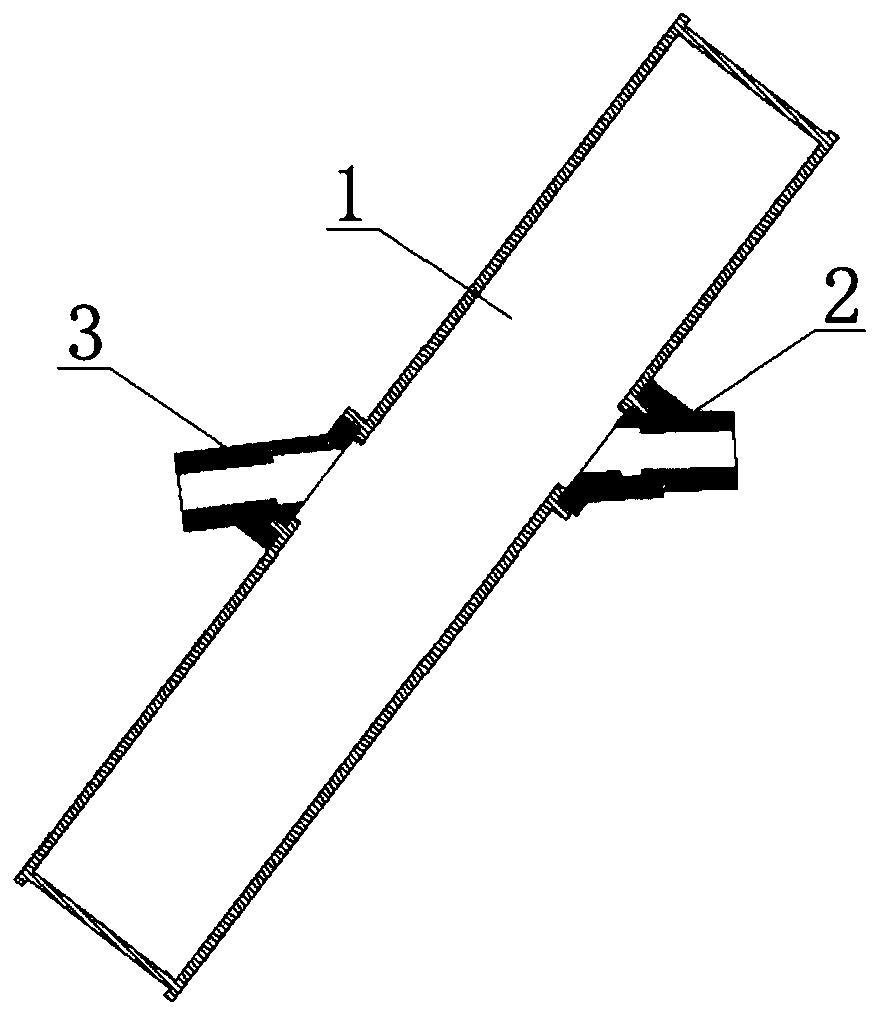

[0087] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0088] The subway station of the western section of the Israeli Red Line is located under the main road of Tel Aviv, where there is a large main power supply pipe gallery with a diameter of 3.2 meters obliquely intersecting with the foundation pit. Due to the strict requirements of Israel's national conditions, culture, and local municipal engineering, considering factors such as construction period and cost, it is basically unfeasible to relocate the pipeline beyond the scope of the foundation pit. The in-situ suspension protection scheme is adopted. It is a very important technical problem to effectively control the deformation, cracks and suspension safety of the pipe gallery during the excavation process.

[0089] Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com