Rapid target detection and positioning method applied to industrial assembly line

A technology for target detection and localization methods, which is used in character and pattern recognition, instruments, computer parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

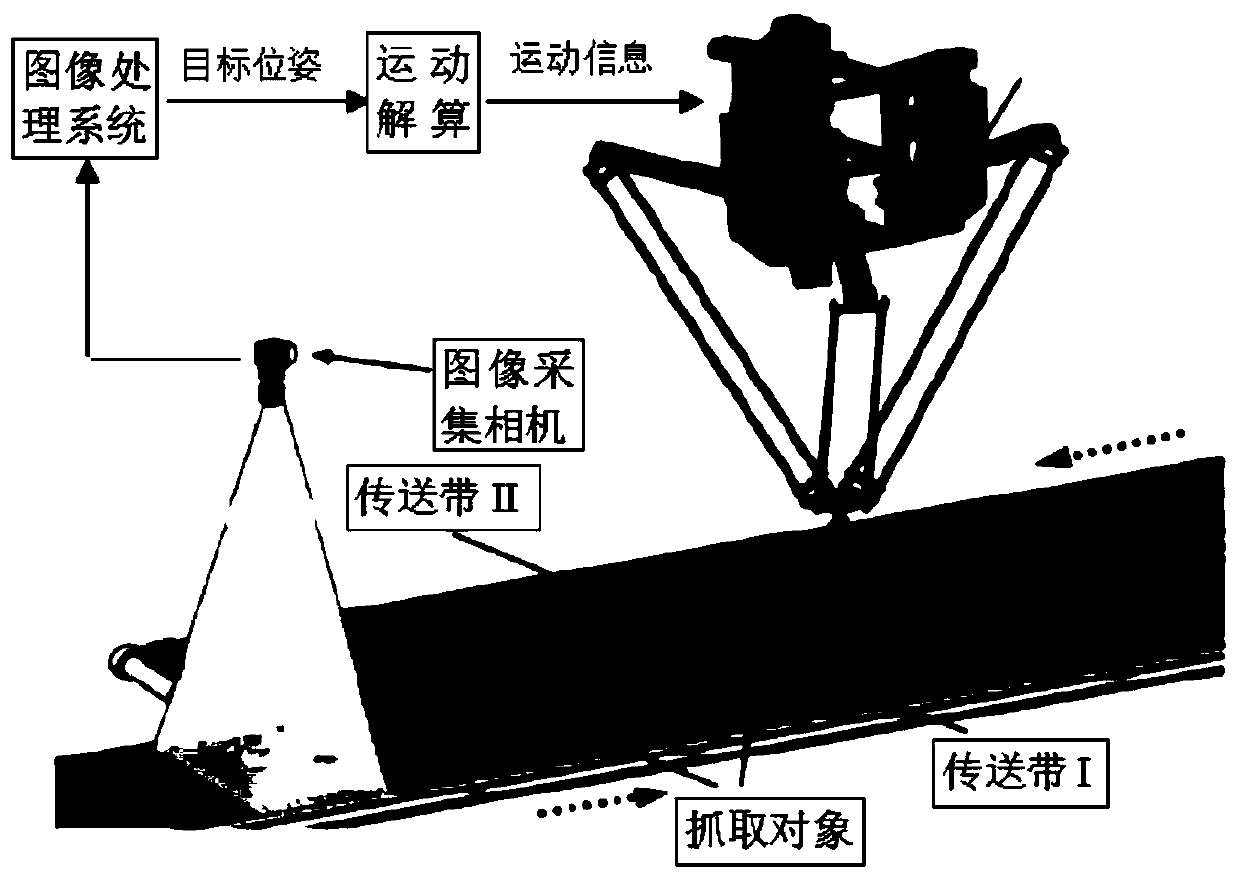

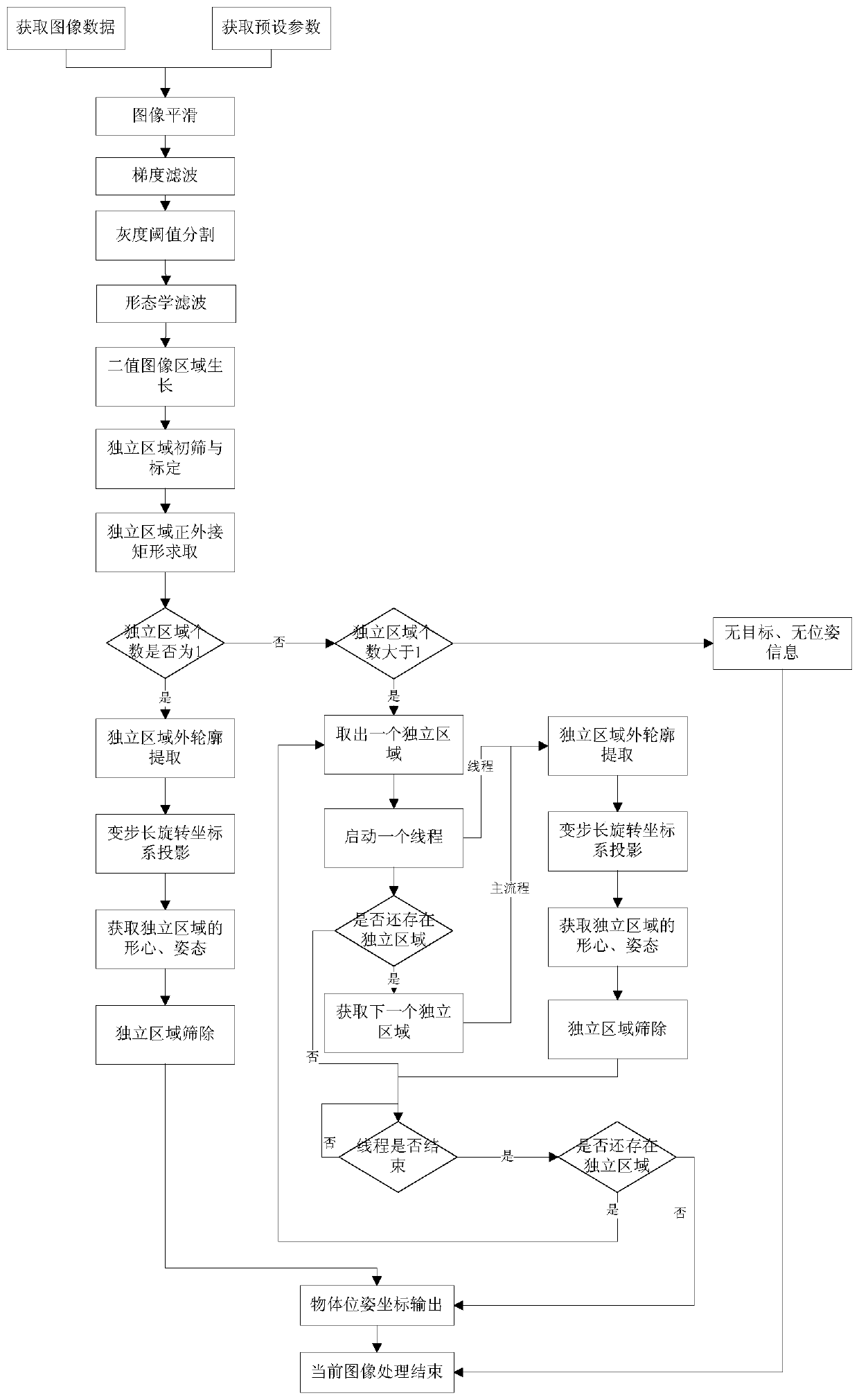

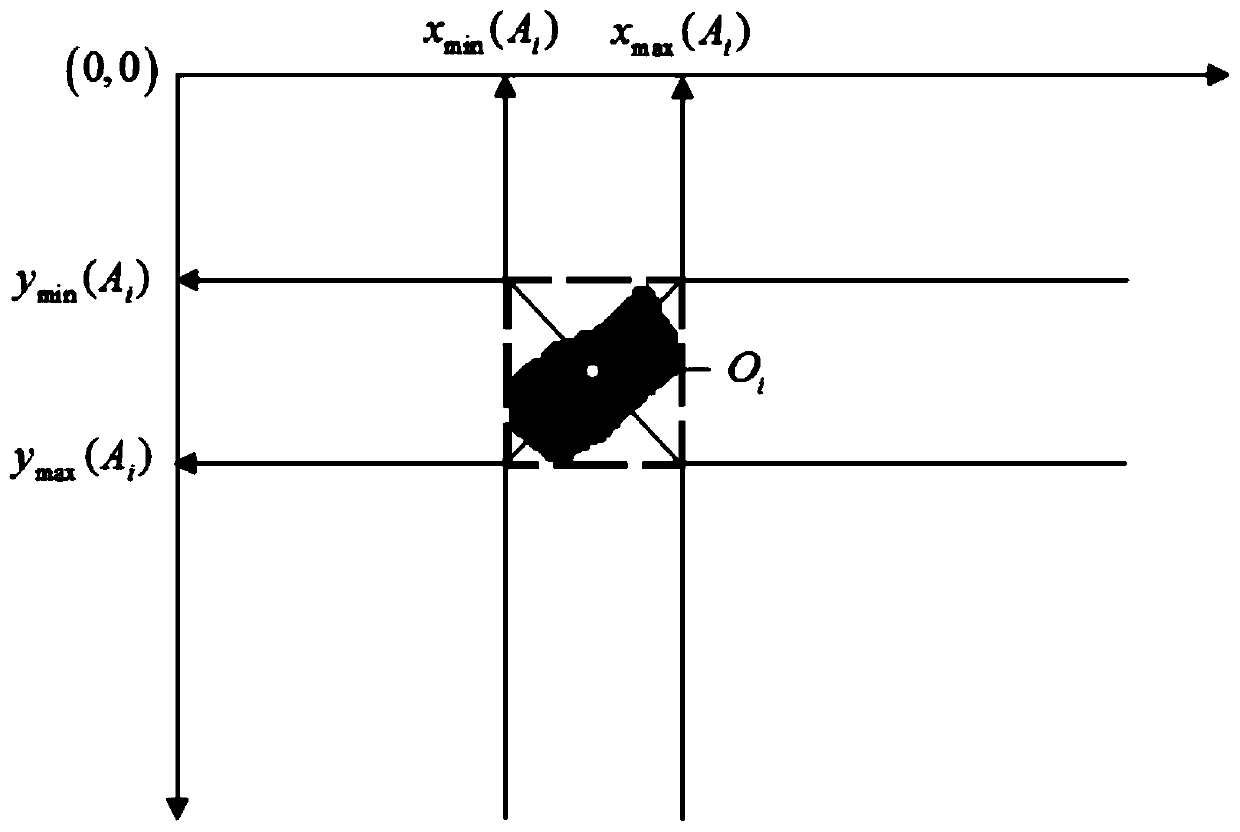

[0047] In order to solve the problem of accurate detection and positioning of single-type single-target, single-type multi-target or multi-type multi-target objects in the target image collected by the machine vision module in the parallel robot system, especially for the target object with uneven gray scale For the problem of detection and positioning, a fast target detection and precise positioning method applied in industrial assembly lines is proposed. This method takes the relaxed imaging size range and wide gray value range of the target as a priori input, eliminates the influence of target gray inhomogeneity through gradient filtering, and integrates basic image processing algorithms such as threshold segmentation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com