Active air cooling and phase change cooling composite battery thermal management system and working method thereof

A thermal management system, phase change cooling technology, applied in secondary batteries, battery temperature control, circuits, etc., can solve problems such as temperature rise, limited heat storage capacity of phase change materials, loss of cooling effect, etc., to achieve improved heat dissipation, Effect of Avoiding Thermal Failure Phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

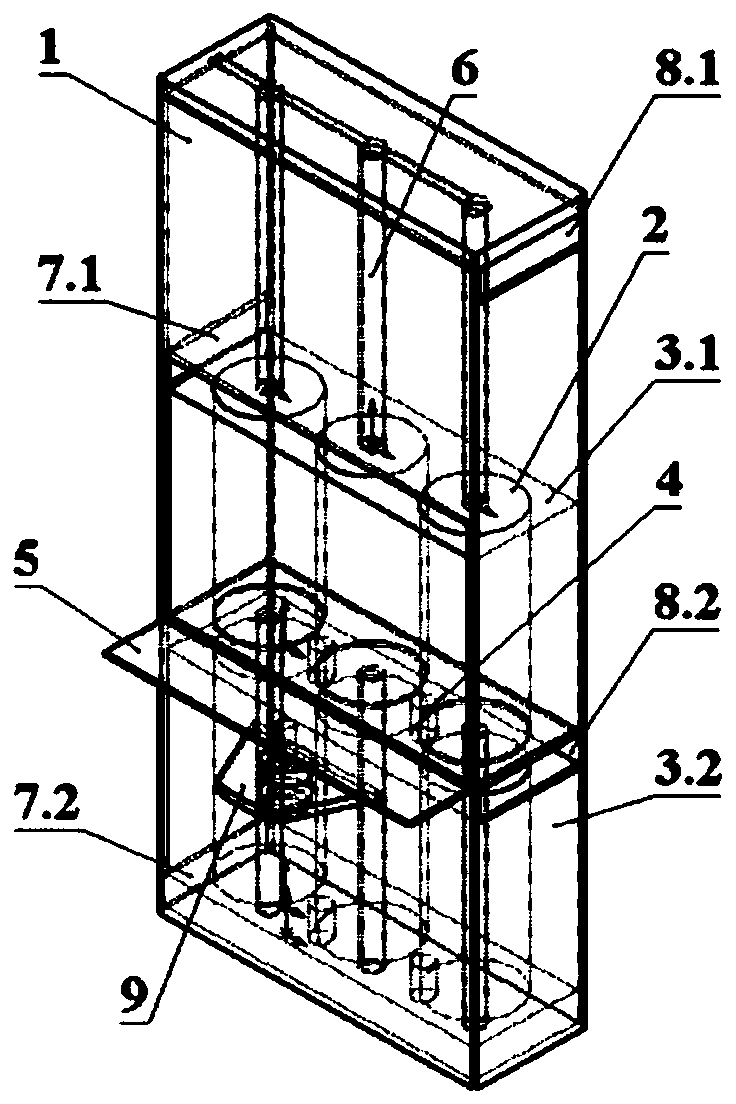

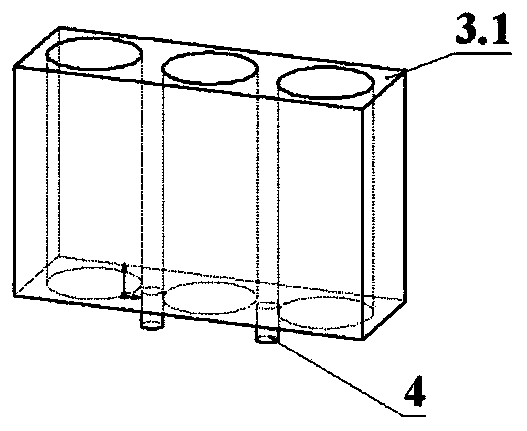

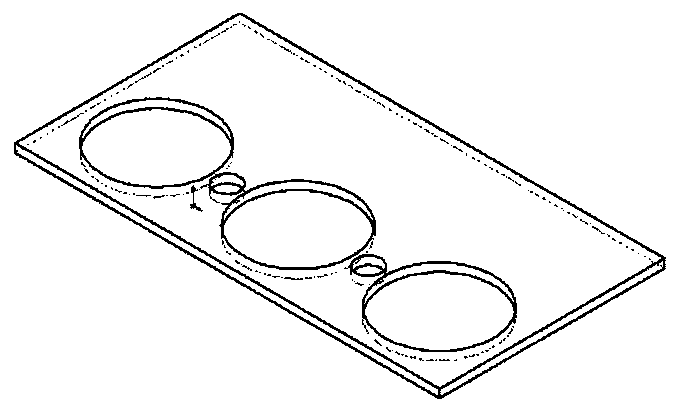

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the active air-cooled and phase-change cooling composite battery thermal management system of the present invention includes a thermal management system box 1, a battery pack 2 arranged in the thermal management system box 1, a first phase-change cooling device 3.1, and a second phase-change cooling device 3.1. Two-phase change cooling device 3.2, connecting column 4, supporting plate 5 and supporting column 6, first air inlet 7.1, second air inlet 7.2, first air outlet 8.1 and second air outlet opened on the side of thermal management system box 1 8.2, the electric push rod 9 fixed on the outer side of the thermal management system box 1; the battery pack 2 is fixed by the support column 6 in the thermal management system box 1, and is in the center of the thermal manage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com