Winch drum brake device

A brake device and drum technology, applied in hoisting devices, spring mechanisms, etc., can solve the problems of long processing cycle, poor braking performance, high manufacturing cost, etc., and achieve low cost, large braking torque, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

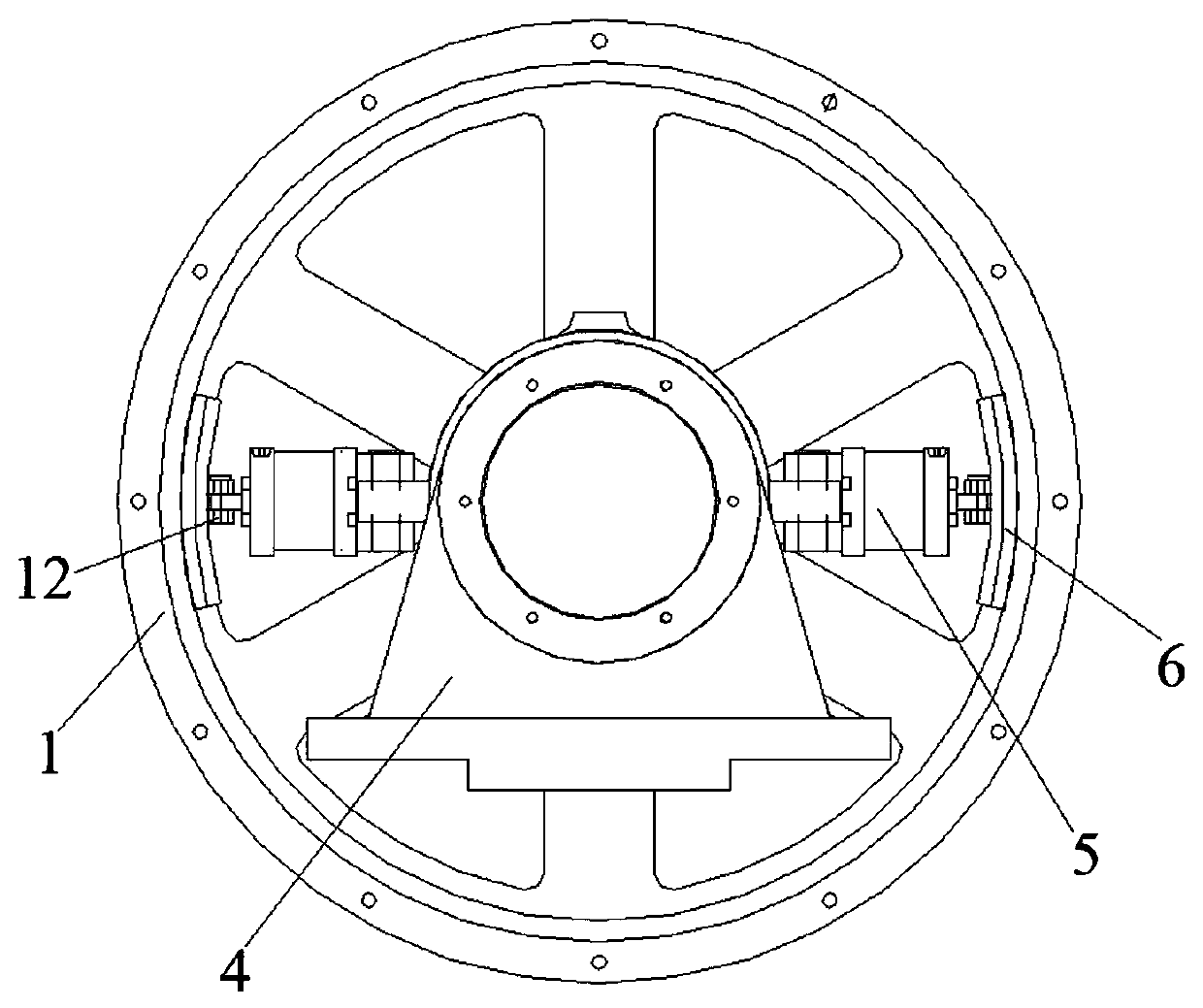

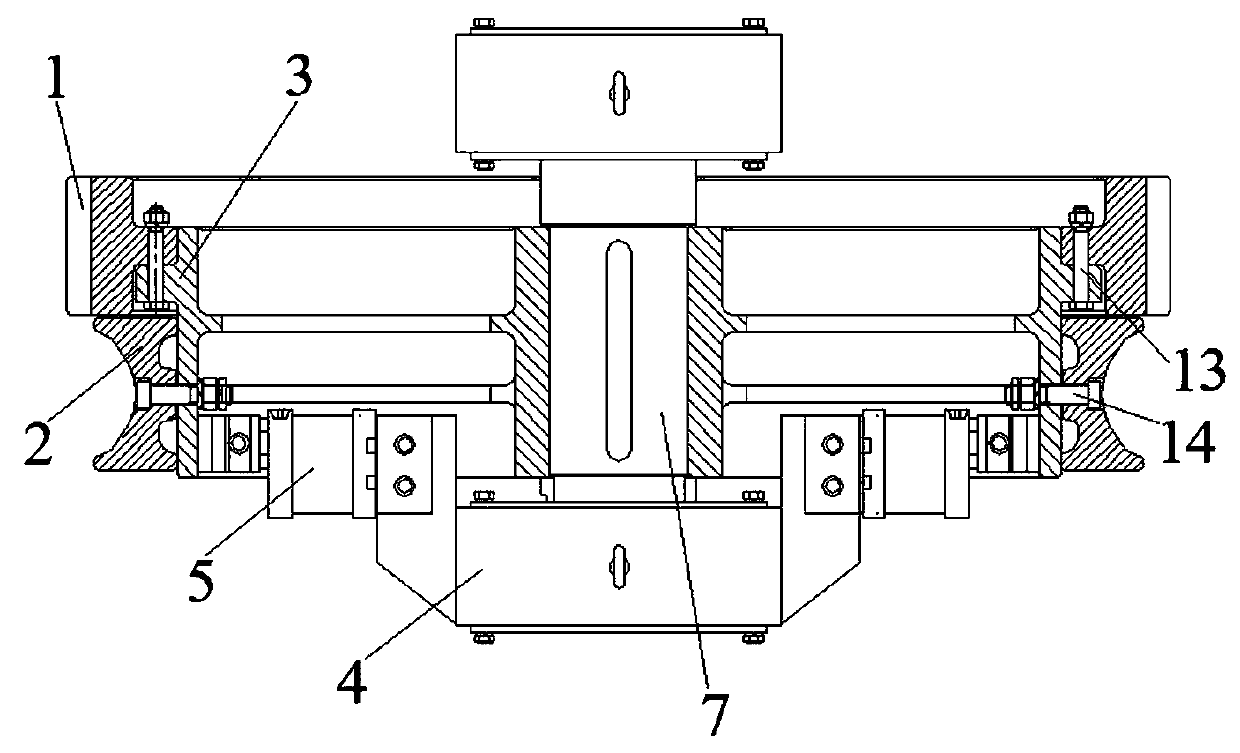

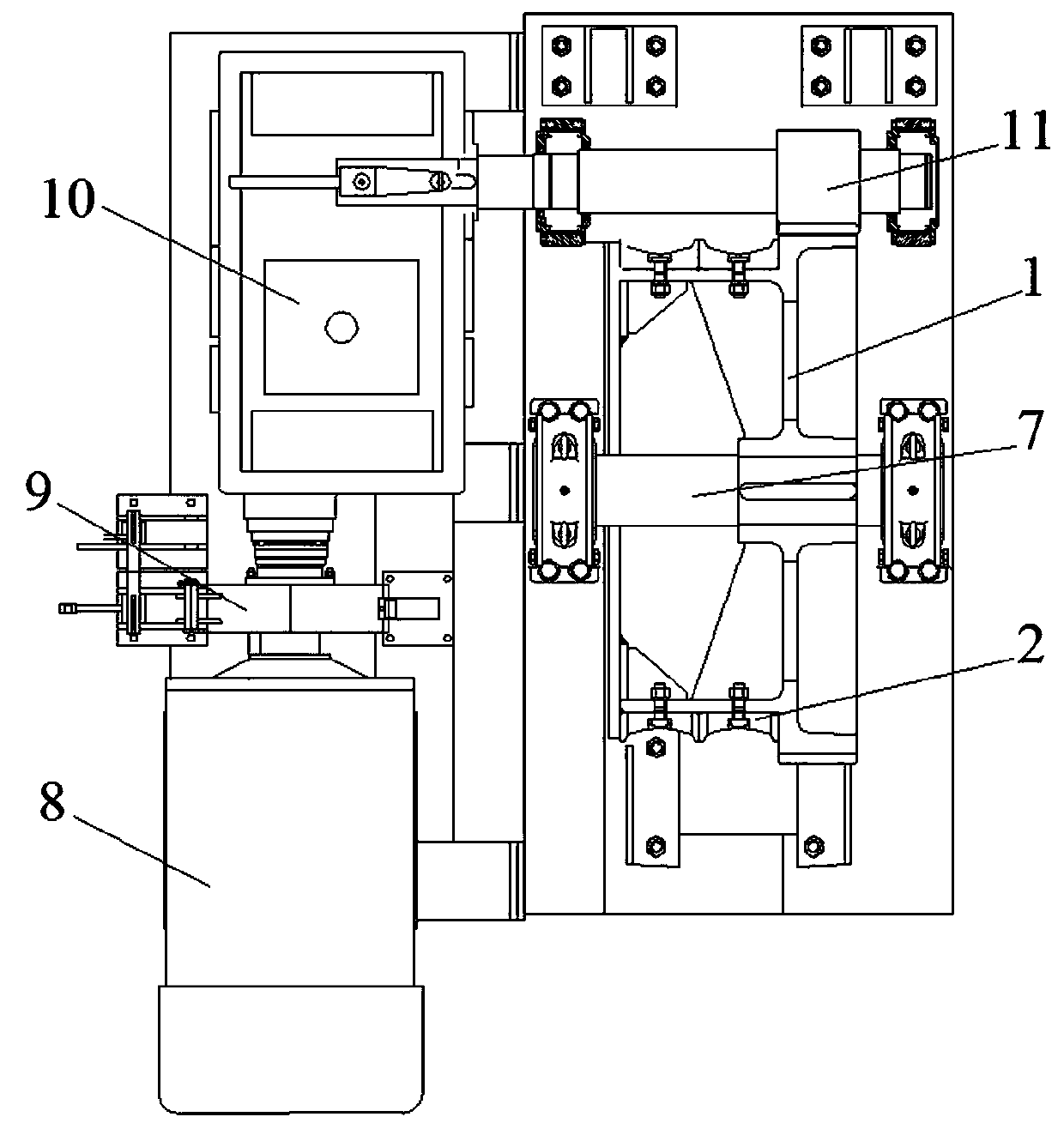

[0015] As shown in the drawings, a winch drum brake device includes two fixed supports 4 with bearings installed at the front and rear, and a rotating shaft 7 is installed through the bearings between the two fixed supports 4, and the rotating shaft 7 is passed through a positioning key. A wheel-shaped winch drum 3 is fixed, and the rear side of the outer ring of the winch drum 3 is fixed with a large ring gear 1 by four transverse bolts 13, and the front side of the outer ring of the winch drum 3 is fixed by four longitudinal bolts. The friction drum 2 of the ring gear 1, the left and right sides of the fixed support 4 on the front side are fixed with horizontally outward brake cylinders 5, and the two brake cylinders 5 are located on the horizontal center line of the circle formed by the winch drum 3, The end of the piston rod of the brake c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com