Multi-cavity independent safety test box, temperature control box and cold plate box

A safety testing, independent technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as reduced work efficiency, complicated wiring, equipment damage, etc., to prevent the expansion of losses, improve test efficiency, and improve wiring. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

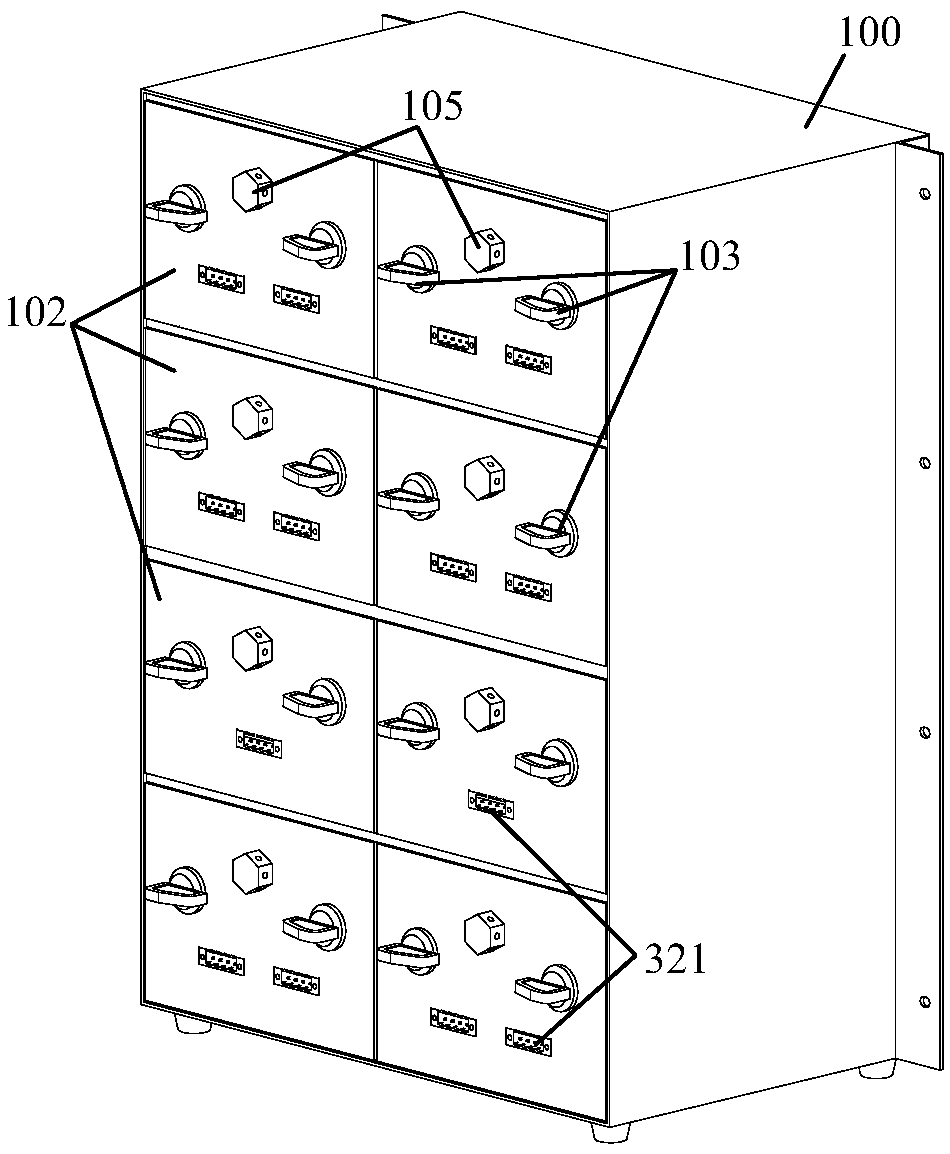

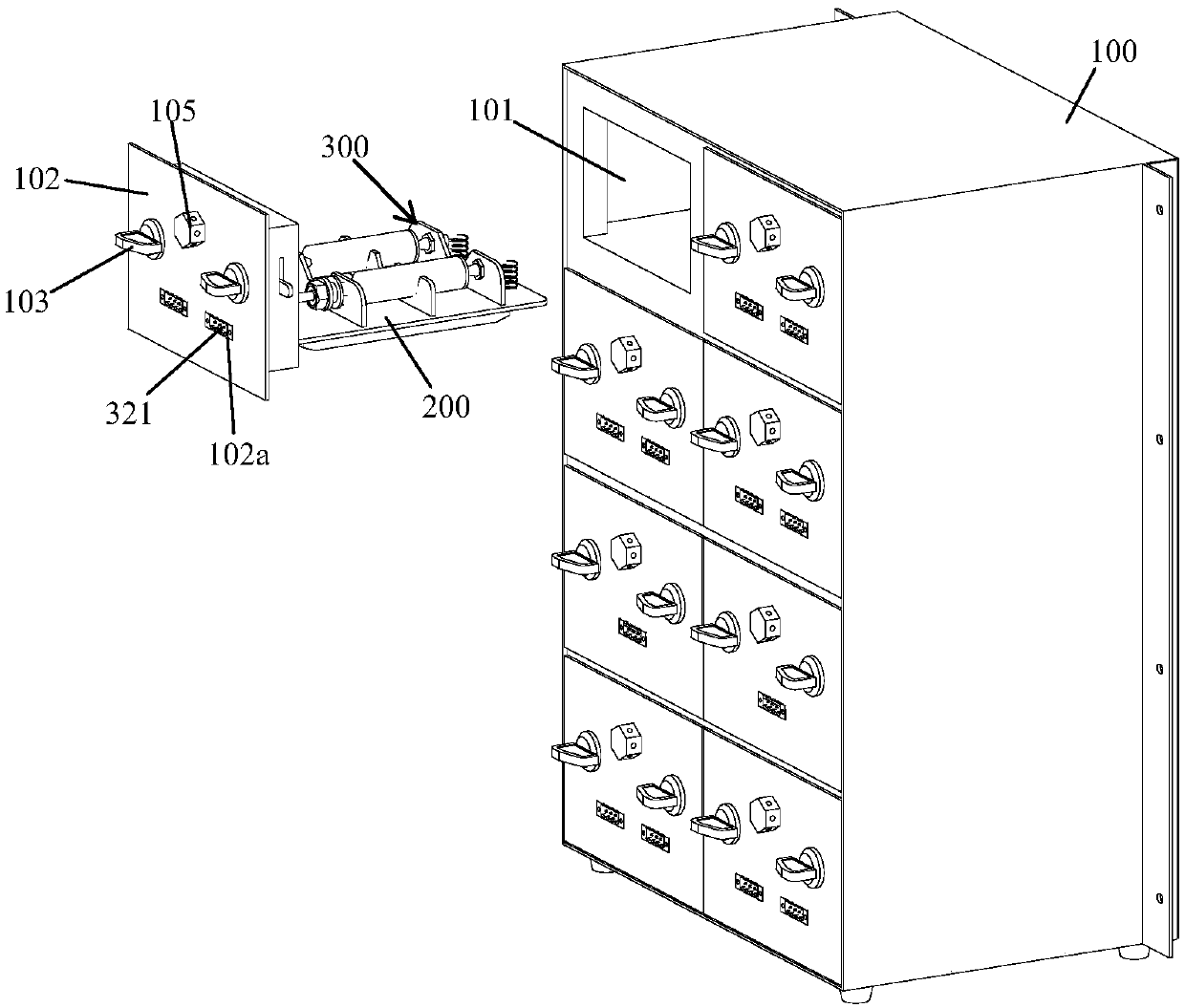

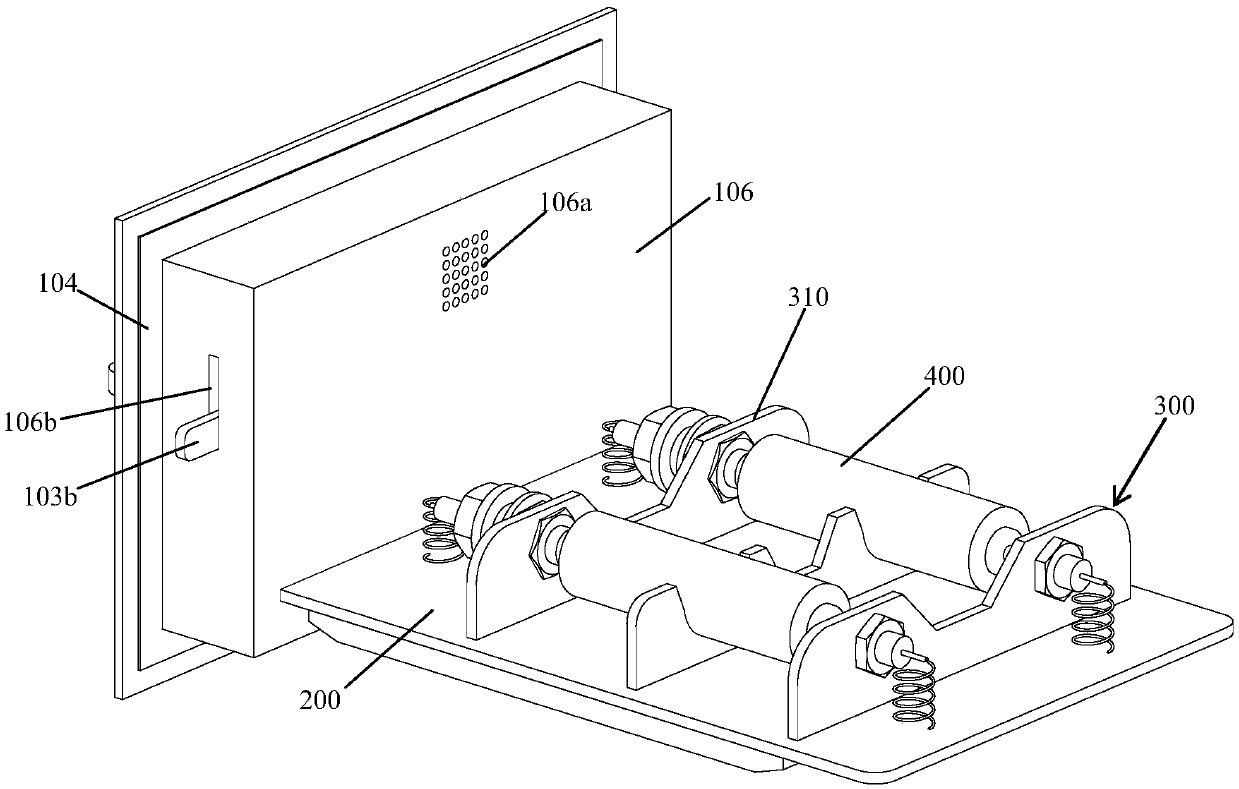

[0036] Such as figure 1 , 2As shown, the present embodiment provides a multi-chamber independent safety test box, including a box body 100, in which a number of independent explosion-proof chambers 101 are arranged, and each of the explosion-proof chambers 101 is respectively provided with The explosion-proof door 102 is provided with two left and right rotary locks 103 on the explosion-proof door 102. The rotary lock 103 includes a main part 103a and a rotating plate 103b. The main part 103a is installed on the explosion-proof door 102. By rotating the main part 103a The rotating handle on the top can control the rotation of the rotating plate part 103b, so that the rotating plate part 103b can be stuck on the inner side wall of the explosion-proof chamber 101 door position.

[0037] The box body 100 is made of thin metal plate, which has good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com