Gantry type full-automatic pure static pressing brick machine

A fully automatic, gantry-type technology, applied in the directions of forming indenters, manufacturing tools, unloading devices, etc., can solve the problems of inconvenient demoulding, inconvenient fabrics, poor automation effect, etc., to solve the problem of poor automation effect and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

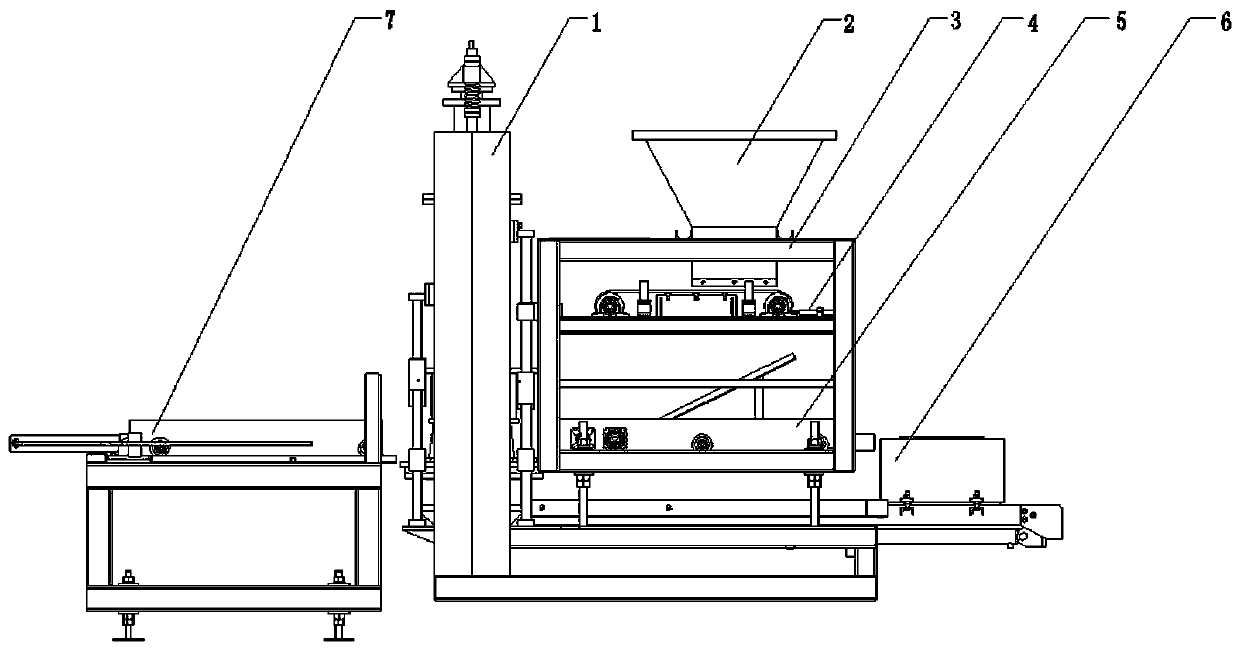

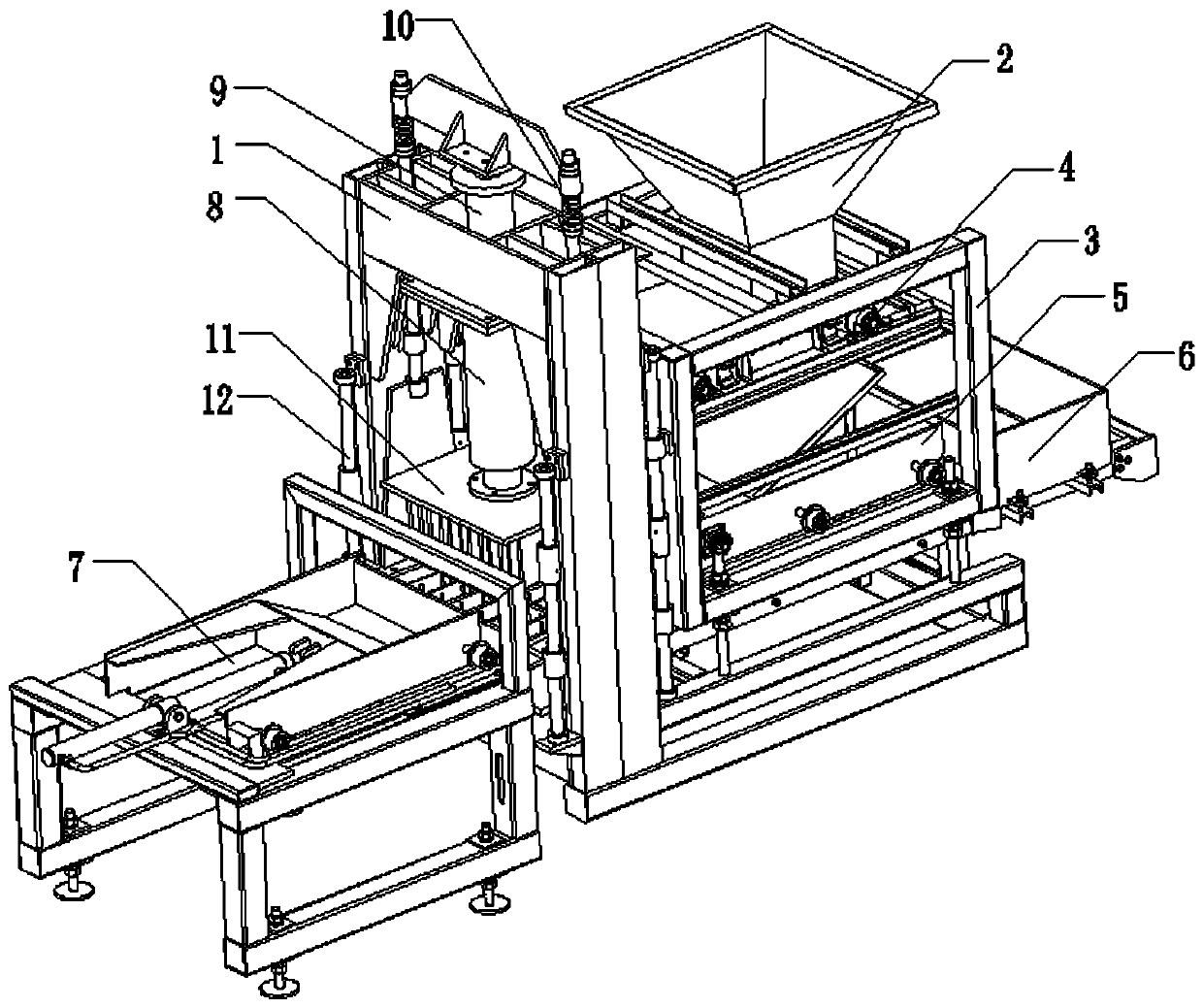

[0017] Embodiment 1: According to figure 1 and figure 2 , a gantry-type fully automatic pure static pressing brick machine, which includes a gantry main frame 1 composed of beams and columns; a sub-frame 3 is provided behind the gantry main frame; a hopper 2 is provided in the sub-frame; the hopper Conveyor belt 4 and distributor 5 are provided below; the back of the distributor is provided with plate feeder 6; the front of the main frame of the gantry is provided with a fabric device 7; A mold 11 composed of a mold cover; the top of the mold is provided with a pressing top 8; the top of the beam of the gantry machine is provided with a stripping top 9; the column of the main frame of the gantry is provided with two vertically distributed balance shaft 10; the balance shaft is connected with the stripping top through a cross brace; the four corners of the mold are respectively provided with vertically connected guide posts 12; the columns of the main frame of the gantry are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com