One-time enameling and low-temperature firing glass lining glaze for oil field pipeline corrosion prevention, as well as preparation method and applications

A low-temperature firing, glass-lined technology, applied in the field of glass-lined glaze, can solve the problems of slow production speed, high firing temperature, complicated production process, etc., and achieve the effect of saving energy, reducing high-temperature deformation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

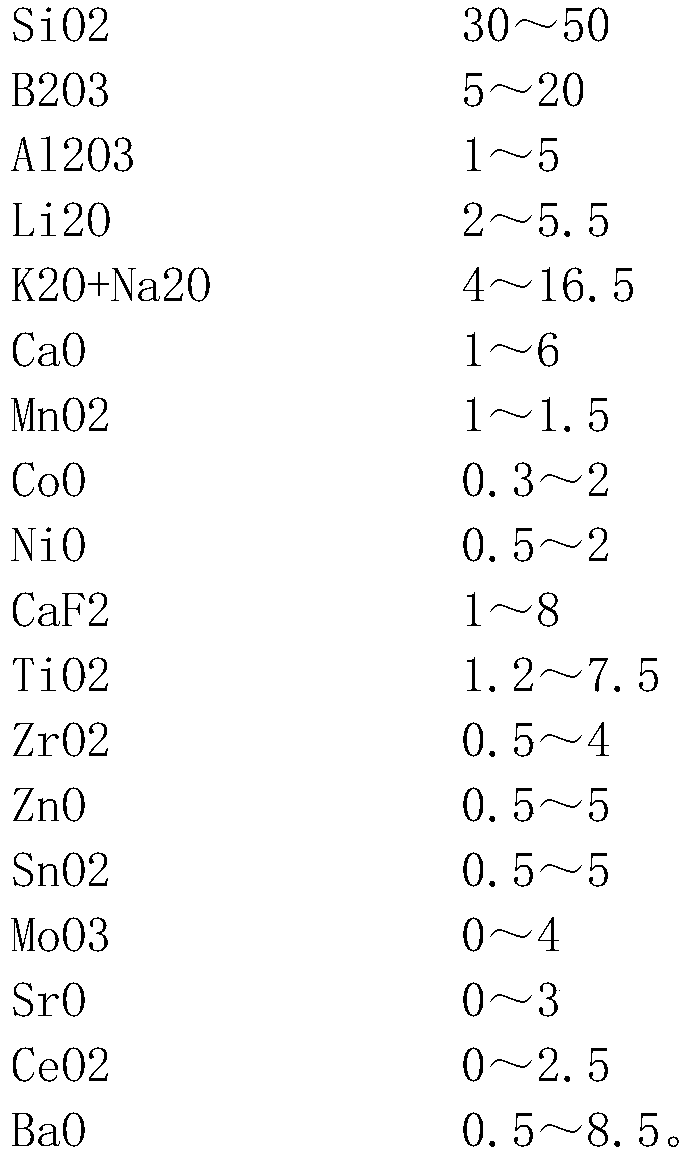

[0028] (1) Composition of glass-lined glaze (by weight):

[0029]

[0030] (2) Preparation method: Melt all the components of the glaze and water-quench into a material block, the melting temperature is 1335 ° C, the melting time is 2 hours, the material block is dried and ball-milled into powder, and the powder is The particle size is 50 mesh.

[0031] (3) How to use: Heat the pipeline after derusting treatment with intermediate frequency, spray the above glaze on the inner surface of the pipeline under the conveyance of compressed air, and then fire the anti-corrosion layer at one time.

Embodiment 2

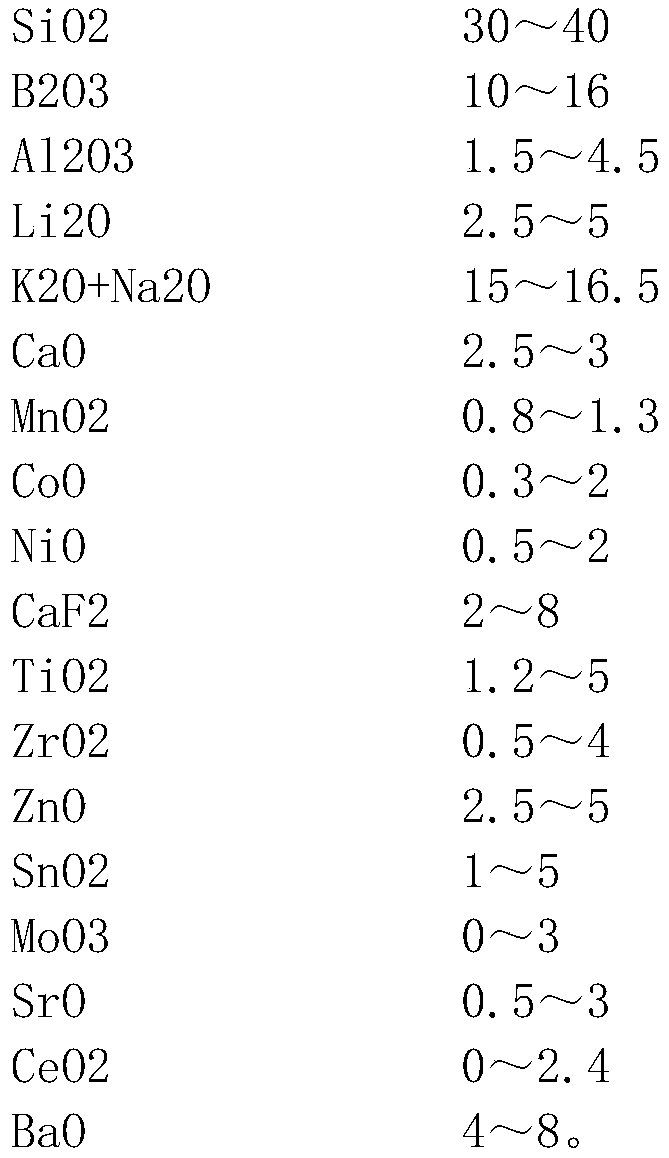

[0033] (1) Composition of glass-lined glaze (by weight):

[0034]

[0035] (2) Preparation method: Melt all the components of the glaze and water-quench into a material block. The melting temperature is 1325°C and the melting time is 3 hours. After the material block is dried, it is ball-milled into powder. The particle size is 150 mesh.

[0036] (3) How to use: Heat the pipeline after derusting treatment with intermediate frequency, transport the above-mentioned glaze under the action of compressed air, spray it on the inner surface of the pipeline, and then fire the anti-corrosion layer at one time.

Embodiment 3

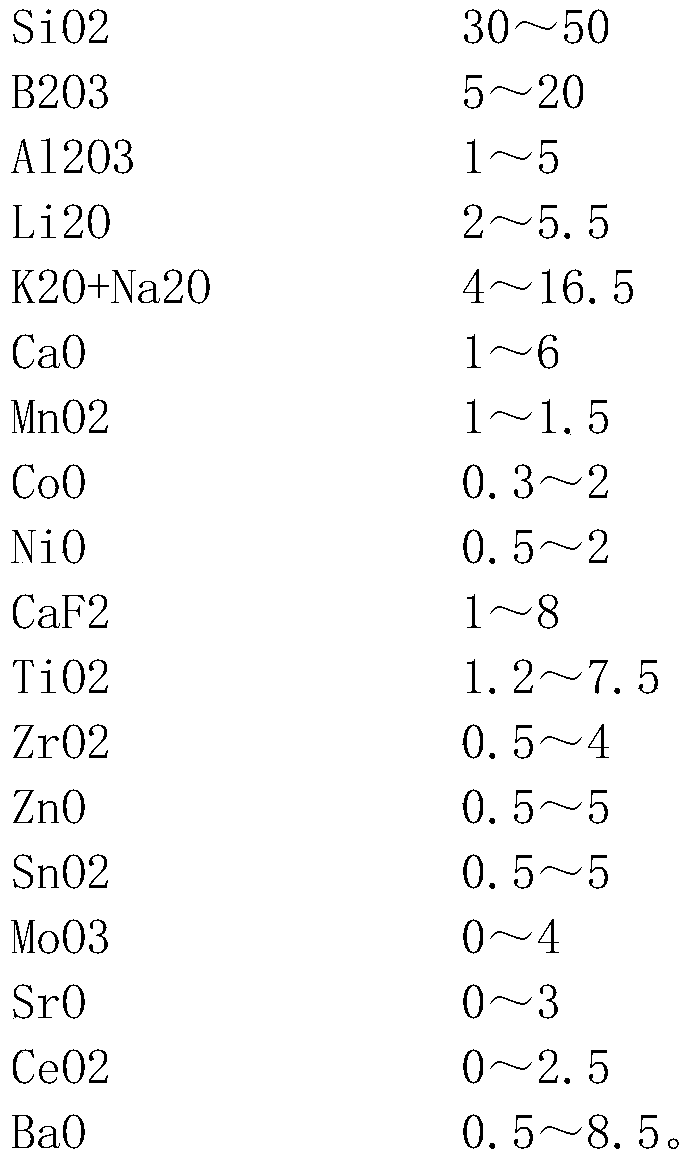

[0038] (1) Composition of glass-lined glaze (by weight):

[0039]

[0040]

[0041] (2) Preparation method: Melt all the components of the glaze and water-quench into a material block. The melting temperature is 1330°C and the melting time is 5 hours. After the material block is dried, it is ball-milled into powder. The particle size is 100 mesh.

[0042] (3) How to use: Heat the pipeline after derusting treatment with intermediate frequency, transport the above-mentioned glaze under the action of compressed air, spray it on the inner surface of the pipeline, and then fire the anti-corrosion layer at one time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com