Valve timing control device

A control device and valve timing technology, applied in the direction of valve device, transmission device, engine control, etc., can solve expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, reference will be made to Figure 1 to Figure 8 Embodiments according to the present disclosure are explained.

[0037] [Schematic Configuration of Valve Timing Control Device]

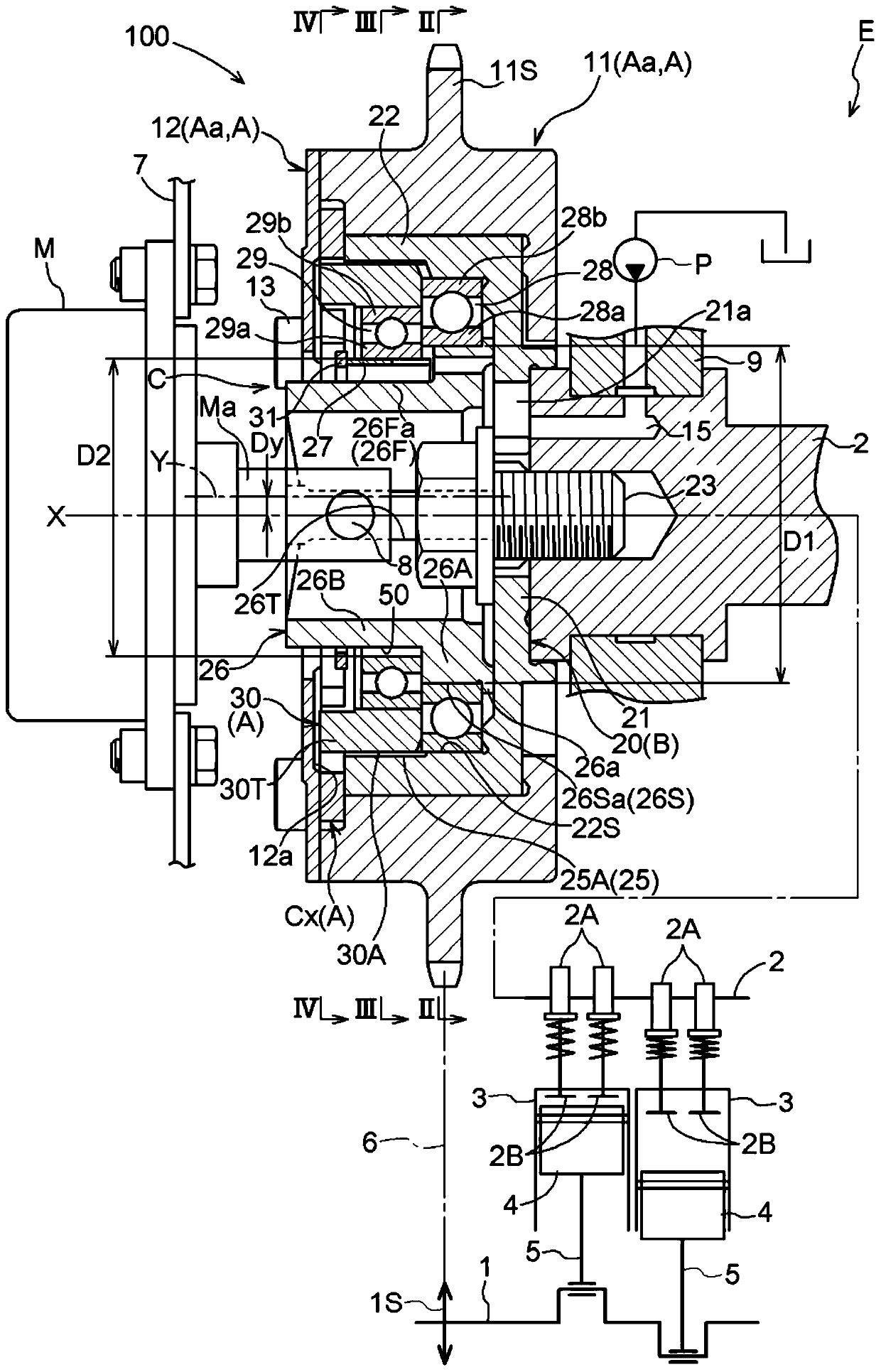

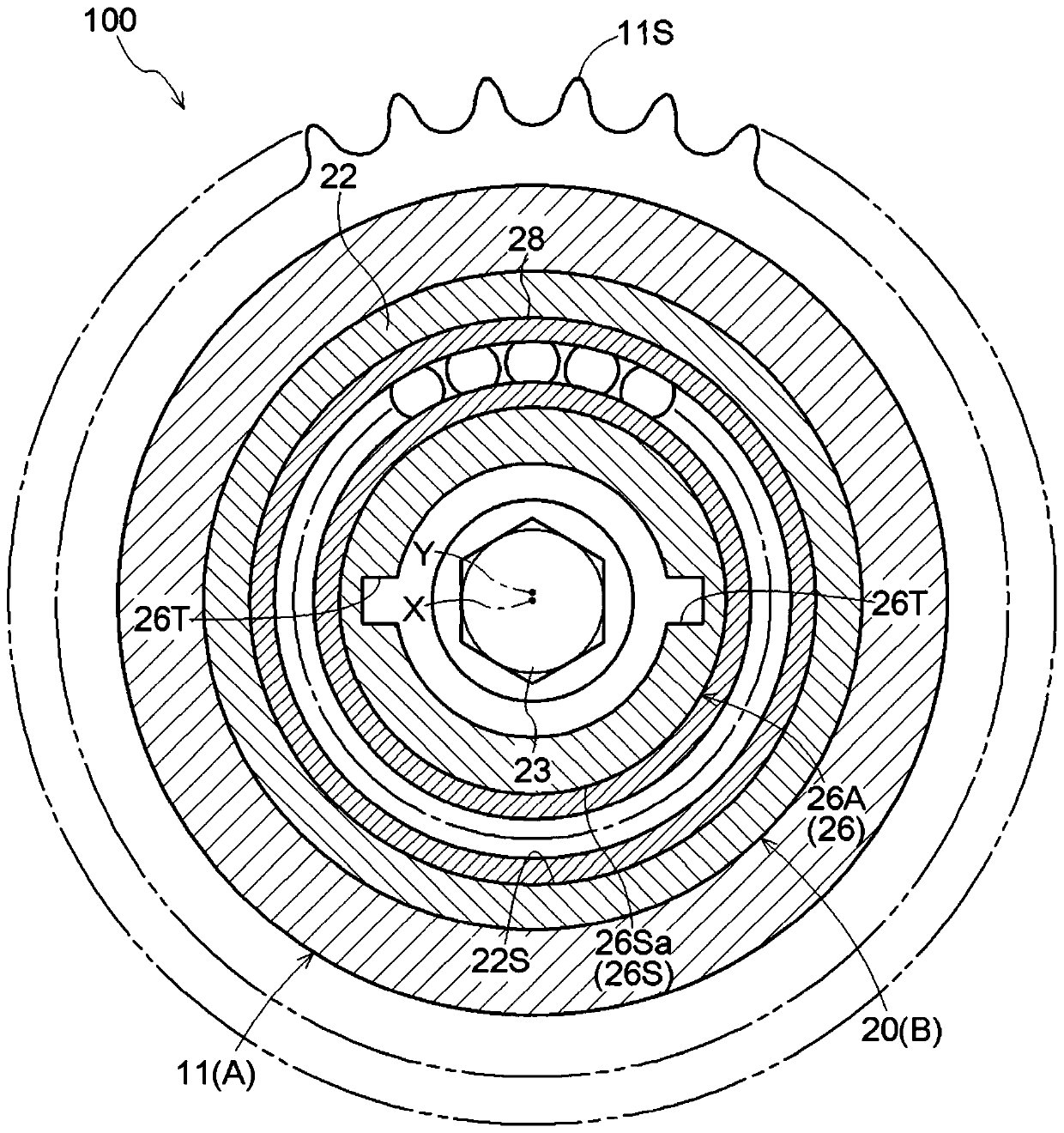

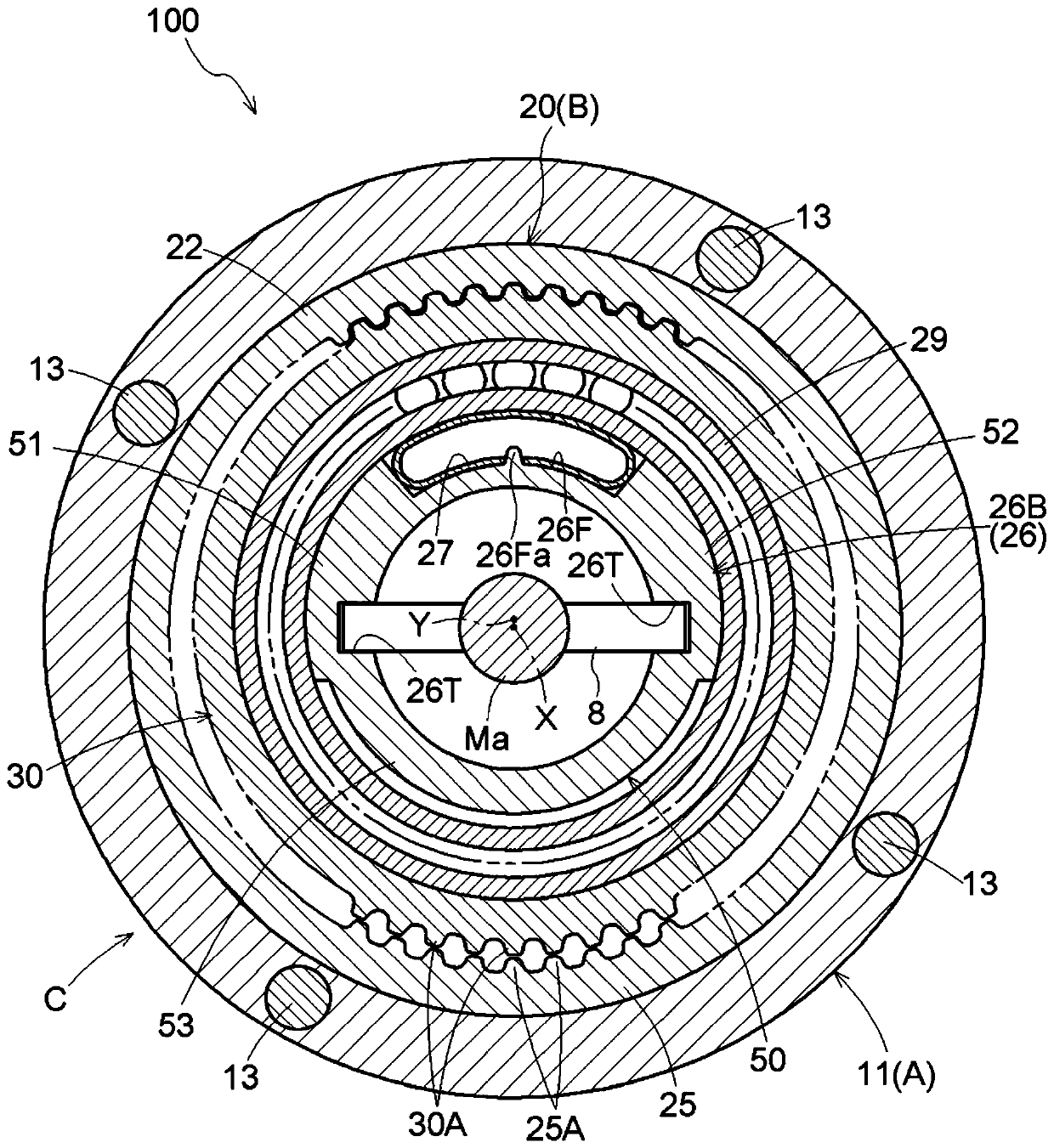

[0038] figure 1 A cross section of the valve timing control device 100 according to this embodiment is shown. Figure 5 An exploded perspective view of the valve timing control device 100 is shown.

[0039] Such as figure 1 As shown, the valve timing control device 100 includes a driving side rotary body A configured to rotate around a rotation axis X in synchronization with a crankshaft 1 of an engine E serving as an internal combustion engine; A member 20 (an example of a first gear) that is provided radially inside the drive side rotary body A and is configured to be integrated with a valve opening and closing intake camshaft 2 (an example of a camshaft) of the engine E centering on the rotary axis X and a phase adjustment mechanism C configured to set the relative rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com