Three-structure-layer diffusion-free plate type laminating film for liquid crystal display

A technology of liquid crystal display and structural layer, which is applied in the field of optical films, can solve the problems of high cost, achieve the effects of reduced packaging and transportation costs of finished products, reduced assembly costs, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

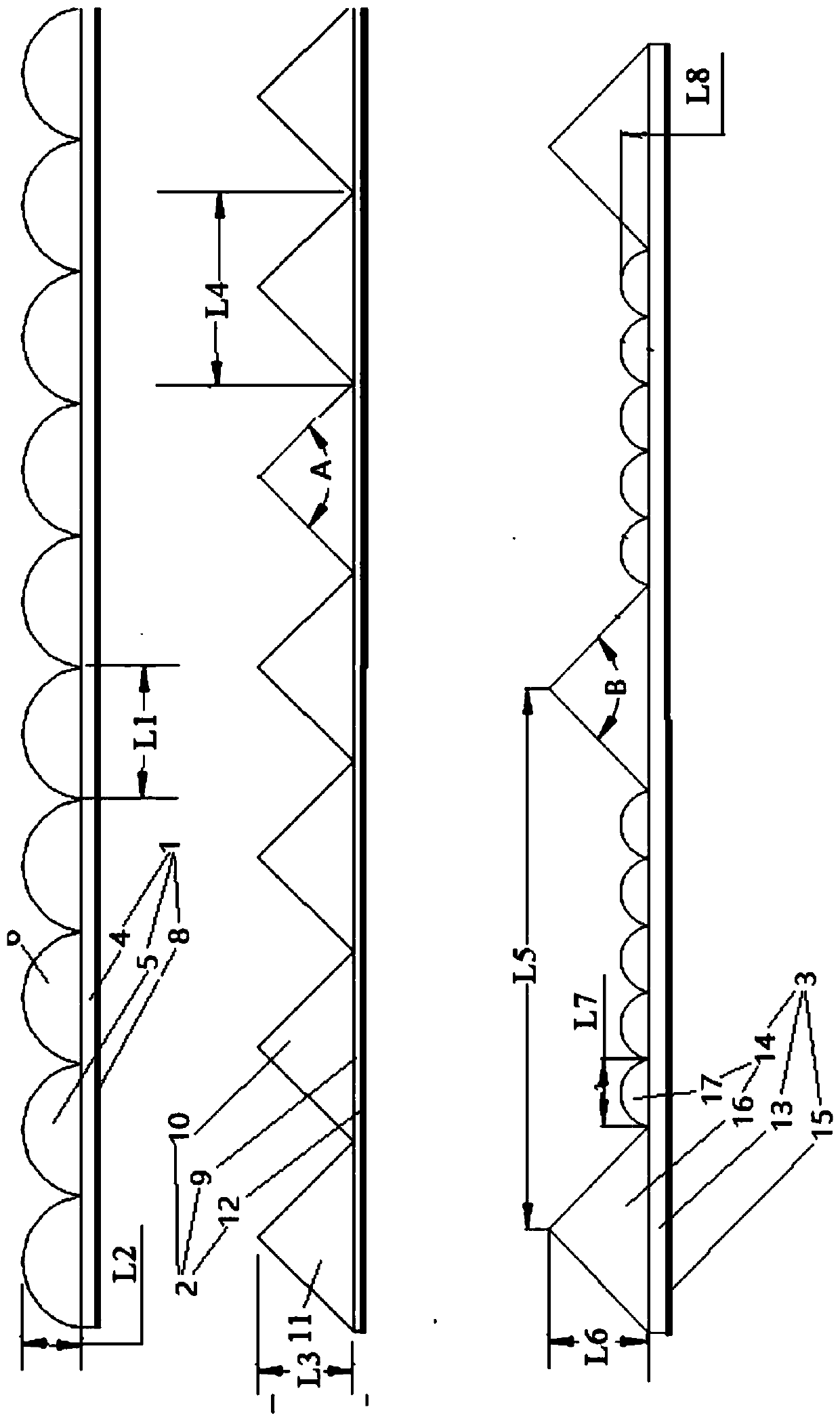

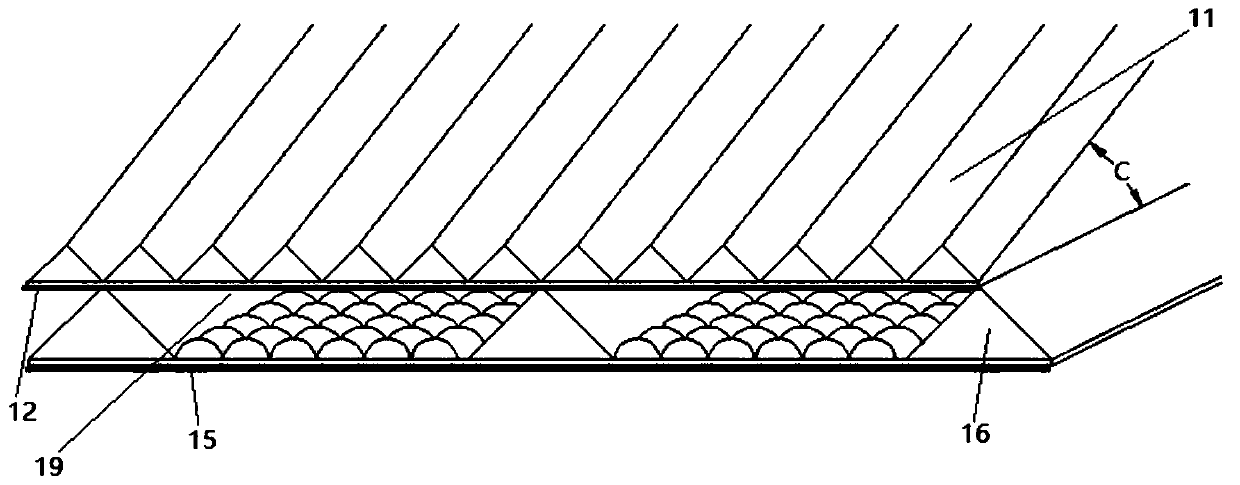

[0022] see figure 1 , figure 2 and image 3 , a three-layer diffusion-free laminated film for liquid crystal displays, comprising a first structural layer film 1, a second structural layer film 2 and a third structural layer film 3 arranged in sequence from top to bottom.

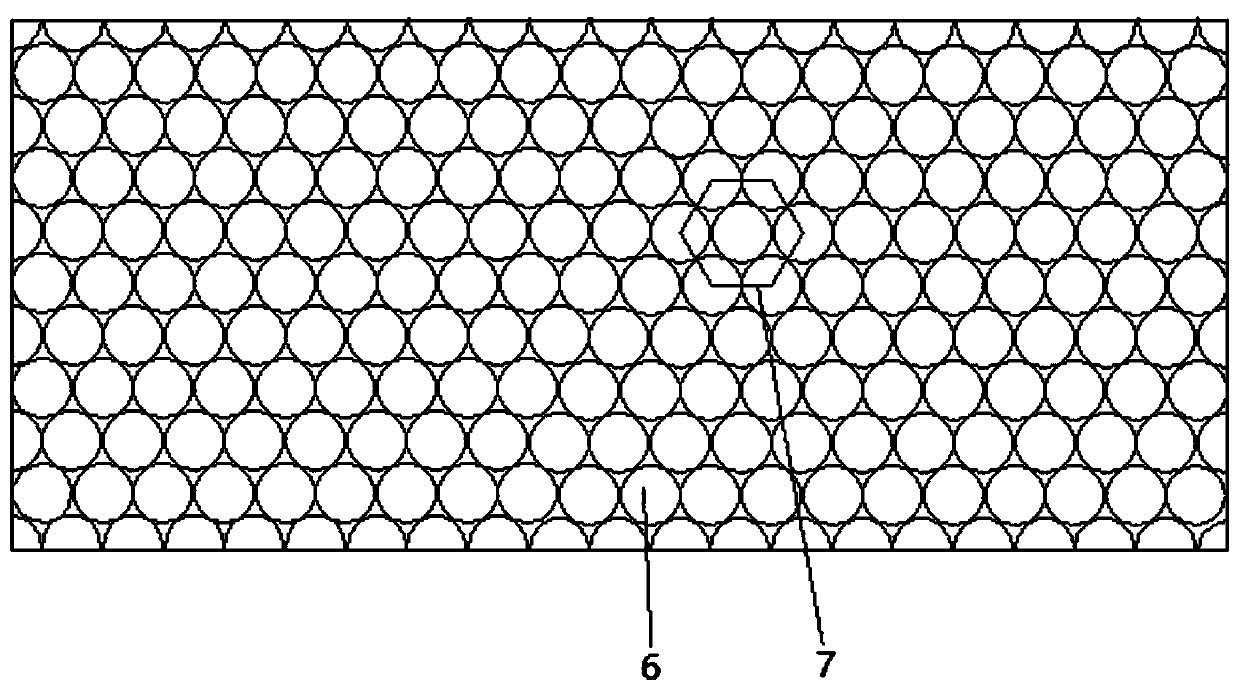

[0023] The first structural layer film includes a first structural layer film part base film 4 and a first structural layer film part micro-convex structure layer 5 arranged on the upper surface of the first structural layer film part base film. The base film of the film portion of the first structural layer has a thickness of 123 microns to 127 microns, preferably 125 microns. The base film of the film portion of the first structural layer is an optical grade PET film. The micro-convex structure layer of the first structural layer is formed by a continuous arrangement of severa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com