Digital AB sheet box pasting machine front gauge automatic adjusting system

An automatic adjustment and pre-regulation technology, applied in container manufacturing machinery, paper/cardboard containers, box making operations, etc., can solve problems such as difficult to control precision, affecting production efficiency and product quality, and low pre-regulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

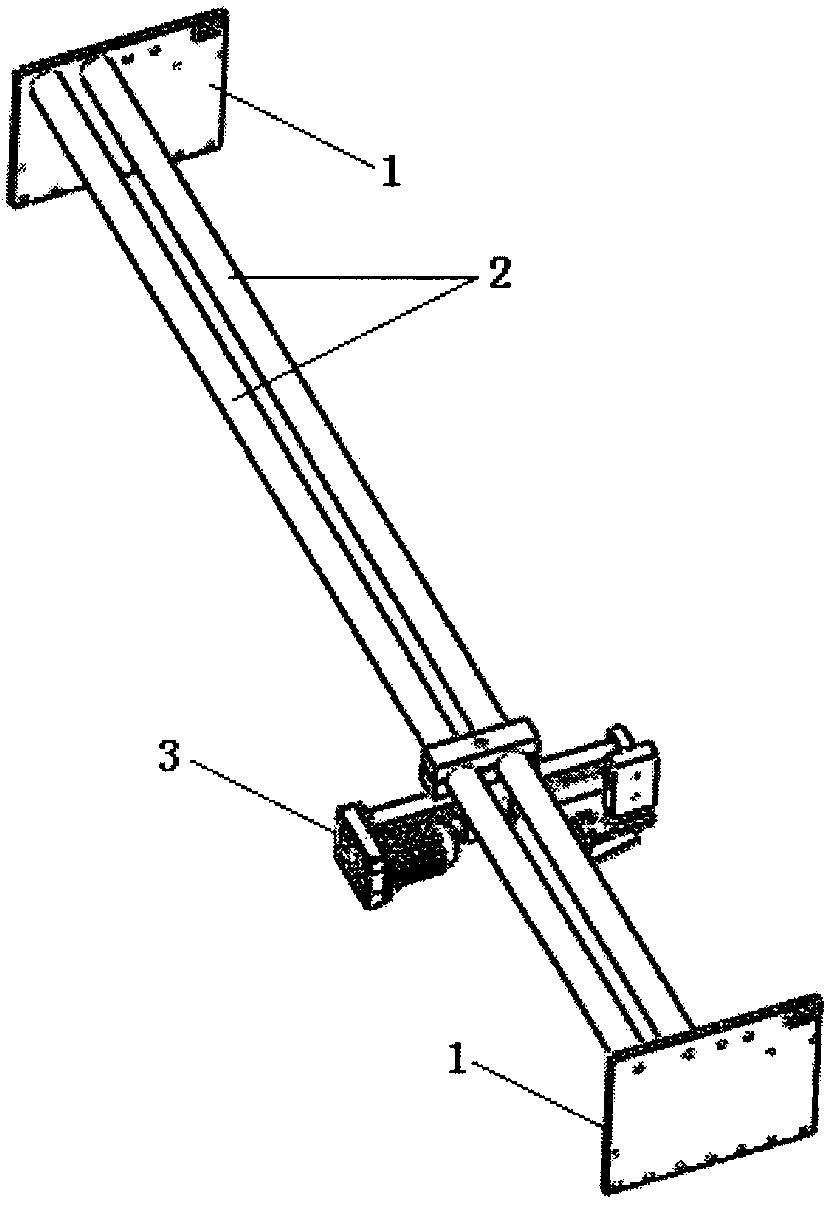

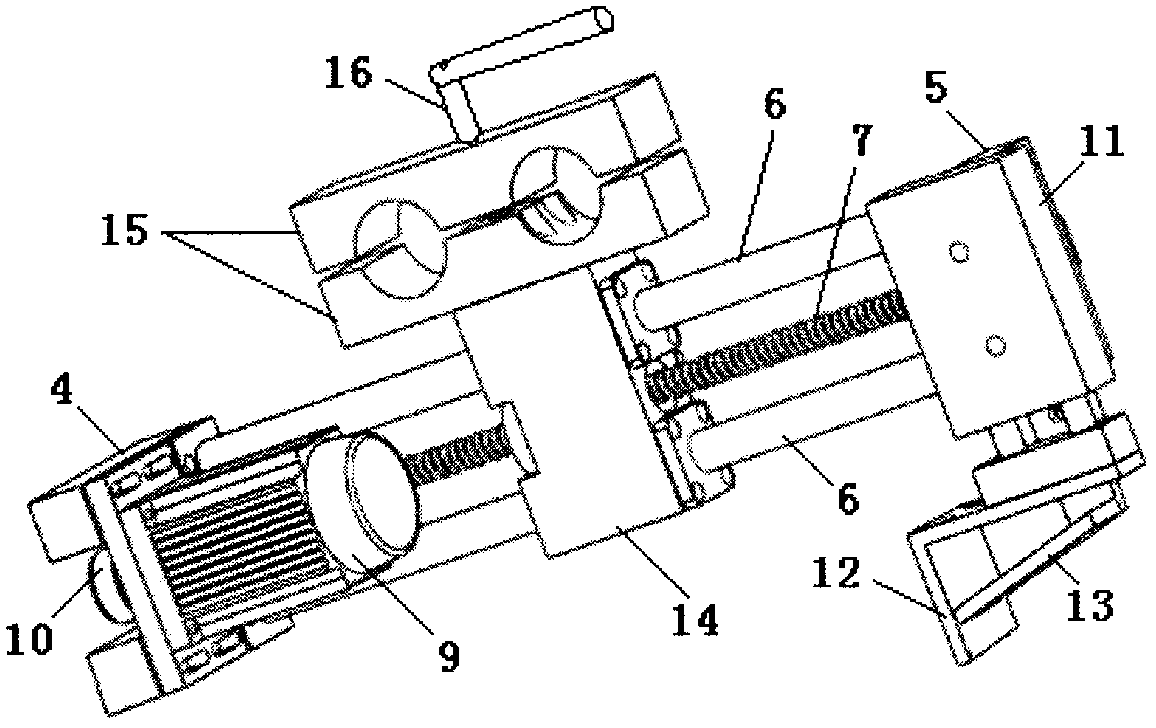

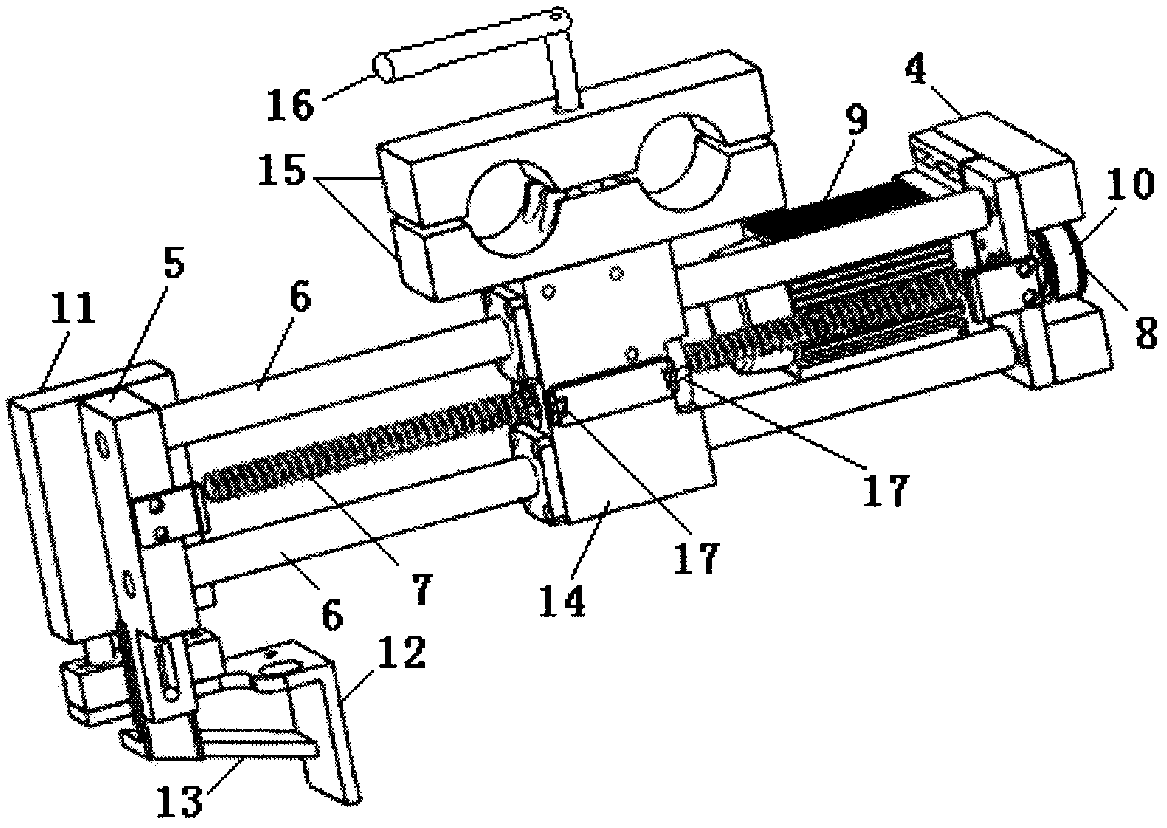

[0021] Embodiment 1: as Figure 1-3 As shown, the technical solution of the present invention is that the automatic adjustment system of the front gauge of the digitized AB sheet folder gluer includes a pair of left and right sliding beams 2 fixed in parallel between the fuselage wall panels 1 and an automatic automatic adjustment system arranged on the left and right sliding beams 2. The adjustment mechanism 3, the automatic adjustment mechanism includes a front fixing part 4, a rear fixing part 5, a pair of front and rear sliding beams 6, a screw 7, a screw wheel 8, a motor 9, a timing belt 10, a front gauge cylinder 11, a front gauge 12, Pressing plate 13, supporting block 14, locking block 15, locking handle 16, limit switch 17, two front and rear sliding beams 6 are vertically fixed between front fixing part 4 and rear fixing part 5, and leading screw 7 is positioned at two Between the front and rear sliding beams 6, one end of the leading screw 7 is installed in the shaf...

Embodiment 2

[0026] Embodiment 2: Control Figure 1-3 , taking the use of 4 sets of automatic adjustment mechanisms 3 as an example, the working process is:

[0027] Determine the number of automatic adjustment mechanisms 3 according to the specifications of the carton sheet and the shape characteristics of the front edge, unscrew the locking handle 16 to move each automatic adjustment mechanism 3 to the corresponding station on the left and right sliding beams 2, and then tighten the lock The handle 16 locks and positions the left and right positions of the automatic adjustment mechanism 3, and inputs the digital information of the shape characteristics of the front edge of the carton piece into the PLC control system of the machine. The driver controls the servo motor or stepper motor to drive the screw 7 to rotate through the synchronous belt 10 and the screw wheel 8, and the rotation of the screw 7 makes the front and rear sliding beams 6 move back from the initial position (zero posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com