Production equipment for paper bag handle module

A production equipment and paper bag technology, applied in the field of paper bag handle module production equipment, can solve the problems of large output of paper bags, difficulty in ensuring efficiency and quality, and achieve the effect of low equipment cost and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

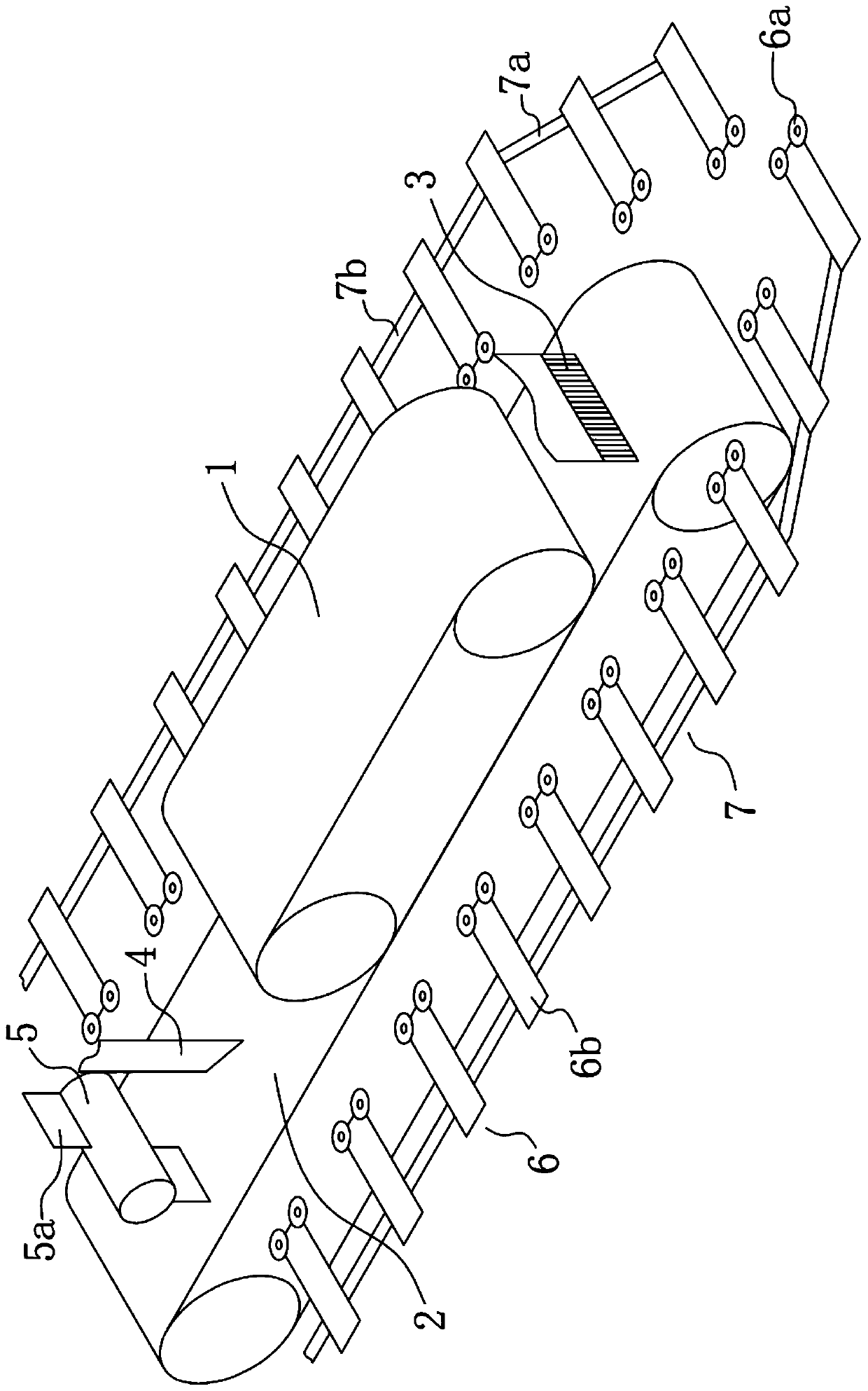

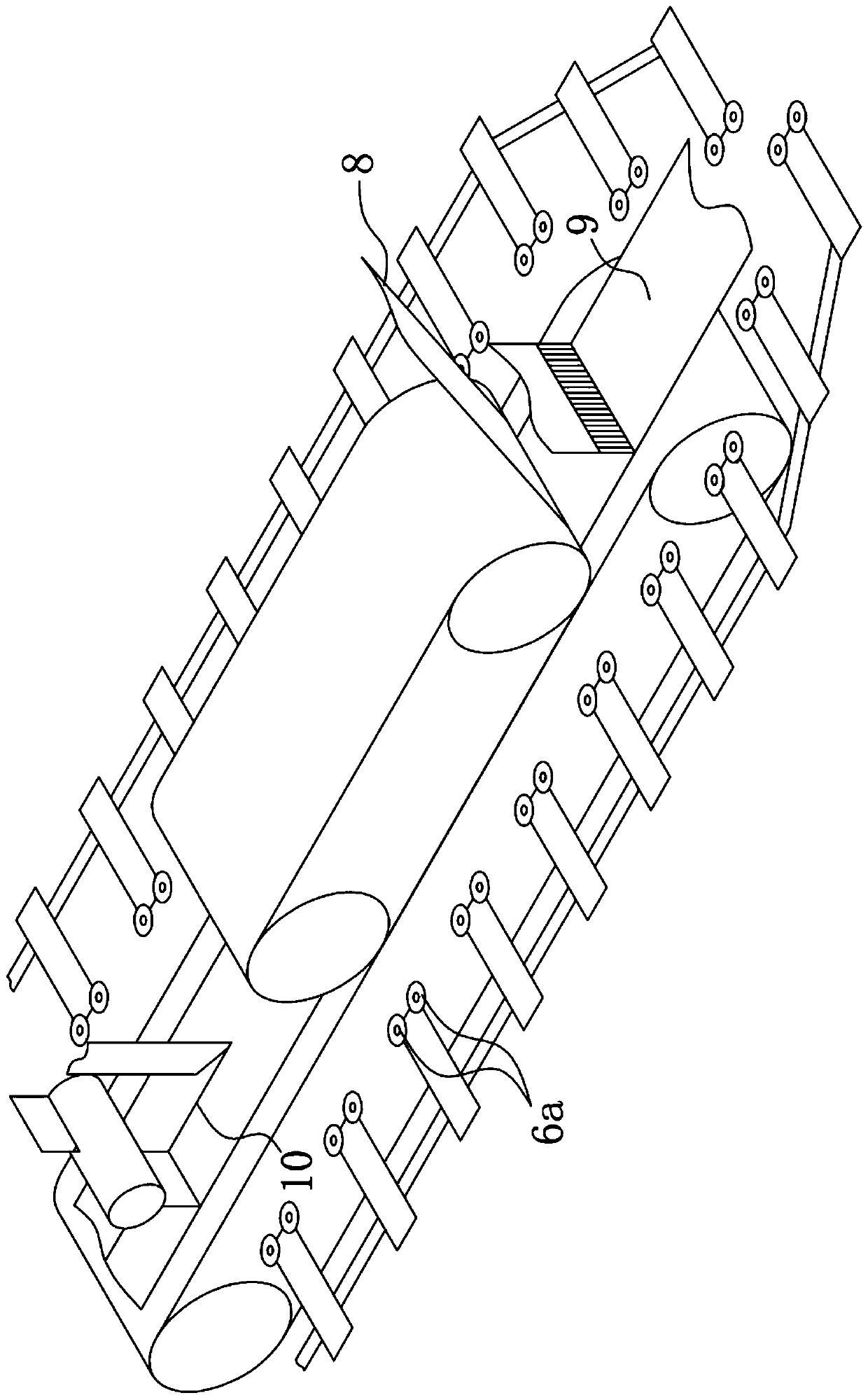

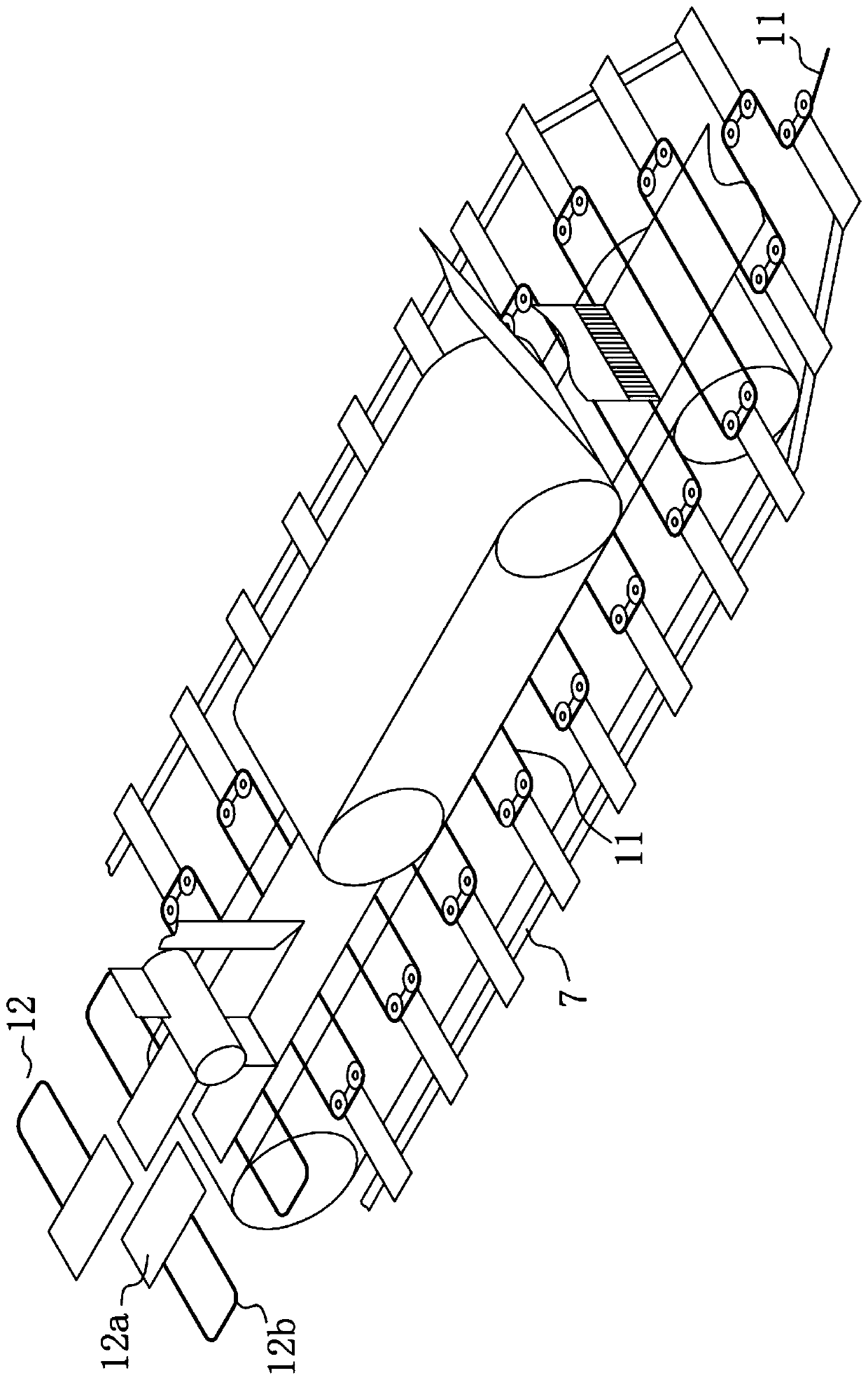

[0031] In order to achieve the purpose of the present invention, a production equipment for paper bag handle modules includes: a transmission mechanism, including an upper conveyor belt 1 and a lower conveyor belt 2 arranged horizontally and parallelly up and down, and the upper conveyor belt 1 and the lower conveyor belt 2 are in contact with each other. The gap for conveying the paper strips, the paper strips include the upper and lower paper strips 8 and the lower paper strips 9 respectively; The two sides of the mechanism are staggered with each other. The pull cord block 6 is provided with a roller 6a for guiding the paper rope 11. The pull cord block 6 has a degree of freedom of horizontal translation parallel to the length direction of the upper conveyor belt 1 and the lower conveyor belt 2. The pull cord block 6 moves the paper The rope 11 is pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com