Structural plane shear strength size effect sample mold manufacturing method based on large number decomposition algorithm

A technology of shear strength and size effect, applied in the field of indoor physical and mechanical testing, to reduce production costs, improve production efficiency, and avoid waste of steel materials and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

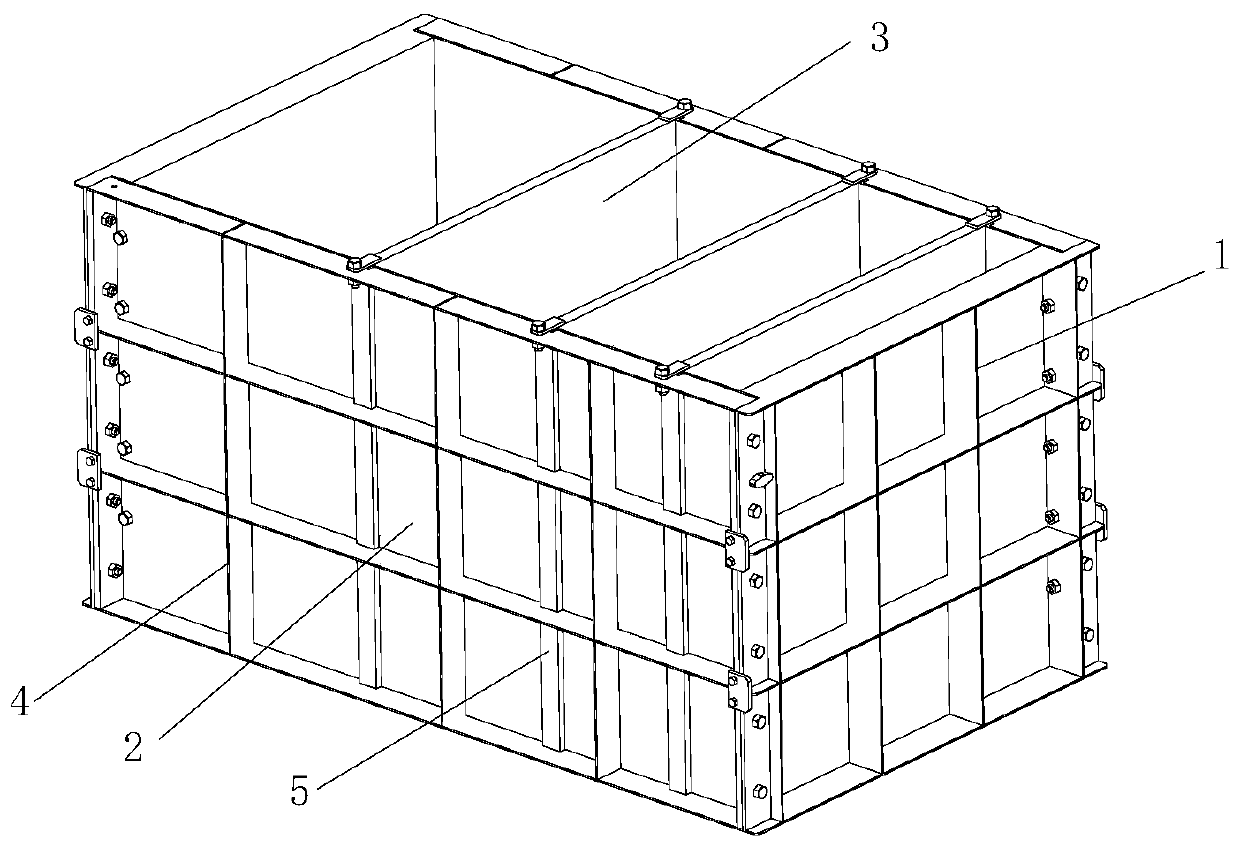

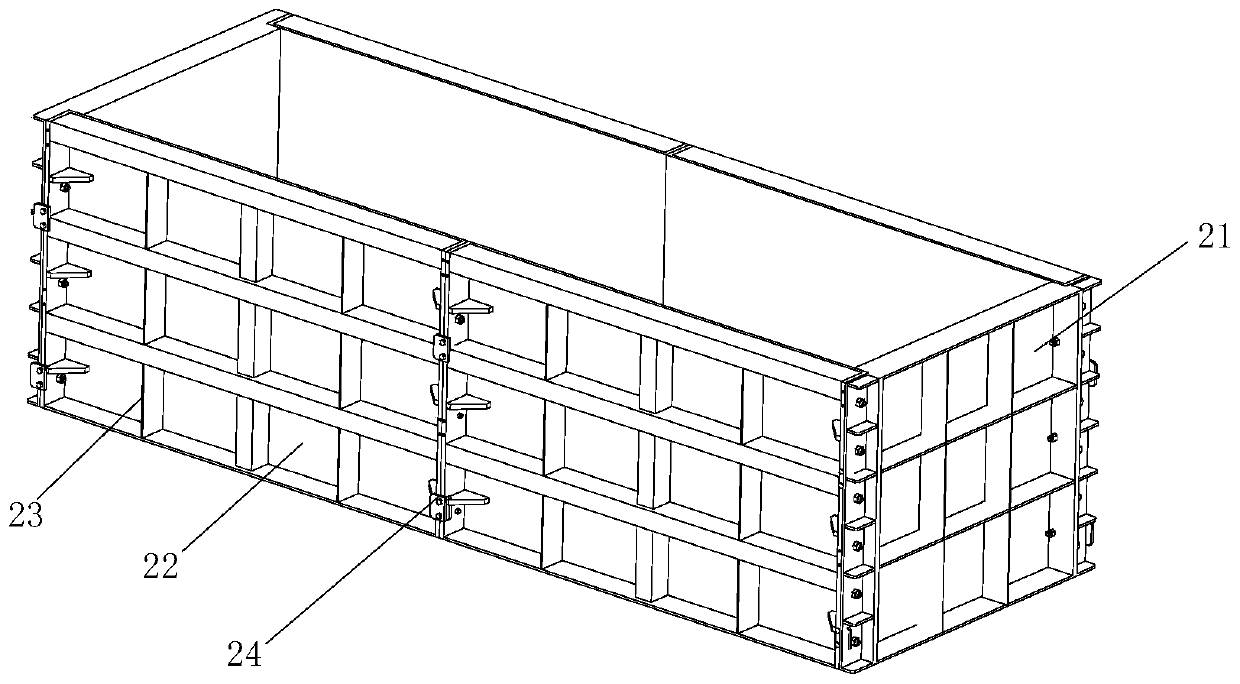

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to figure 1 and figure 2 , a method for making a sample mold based on a large number decomposition algorithm for the shear strength size effect of a structural surface, comprising the following steps:

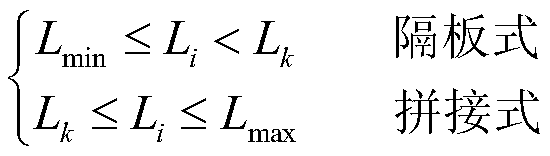

[0032] (1) According to the test requirements of the research on the size effect of the shear strength of the rock mass structural surface, the series sizes of the coiled concrete samples on the structural surface are obtained, forming a length matrix L, and the minimum length in the matrix is L min , the maximum length is L max , the length conforms to the arithmetic sequence as follows,

[0033] L i =L 0 +i×ΔL

[0034] In the formula, L i is the serial length of the i-th sample, cm; L 0 is the minimum length of the sample, cm; ΔL is the interval of the length of the sample series, cm;

[0035] (2) Select parameter L k =roundup(L max / 10), se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com