Film-coated product cleaning mechanism for optical filter production

A cleaning mechanism and filter technology, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the overload operation of the working motor, the waste of cleaning liquid spilled, and the secondary pollution of the filter. and other problems to achieve the effect of reducing energy loss, avoiding spillage, and reducing vacancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as Figure 6-10 As shown, according to the size of the filter, increase or decrease the mounting seat 904 on the outside of the same ring frame 903. The mounting seat 904 slides freely on the outside of the ring frame 903 and is fixed by fastening bolts 907, thereby realizing the control of single cleaning filter. The number of optical sheets, respectively move the first slot 905 and the second slot 906, the first clamping rod 908 and the second clamping rod 909, and move the first clamping rod 908 and the second clamping rod 909 to the same position as the filter The size of the light sheet is roughly consistent with the setting, and then the filter is installed between the first clamping rod 908 and the second clamping rod 909, and the position of the first clamping rod 908 and the second clamping rod 909 is adjusted again, and Fix it by fastening the bolt 907, so that the clamping of the filter by the first clamping rod 908 and the second clamping rod 909 is mor...

Embodiment 2

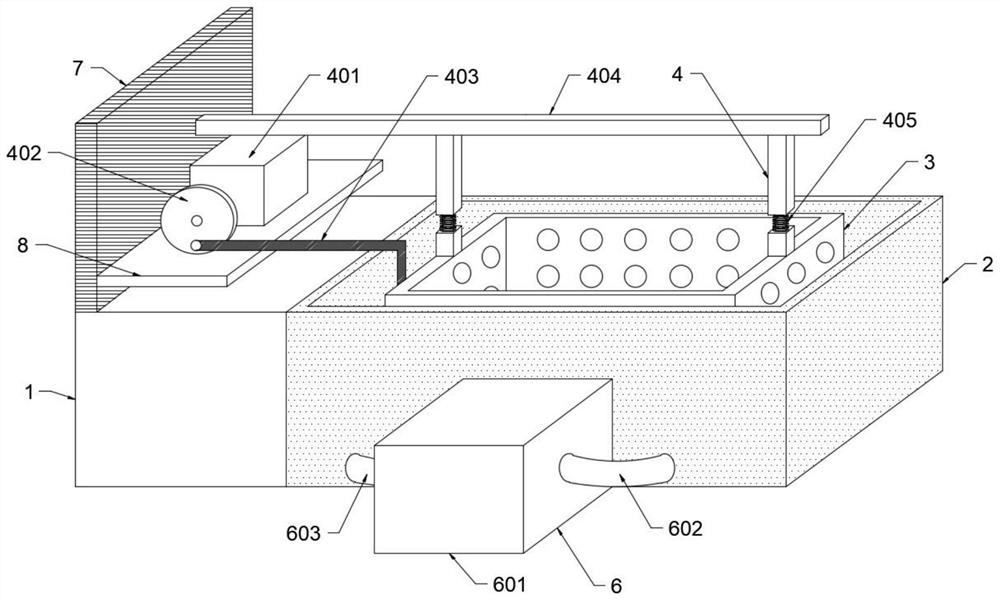

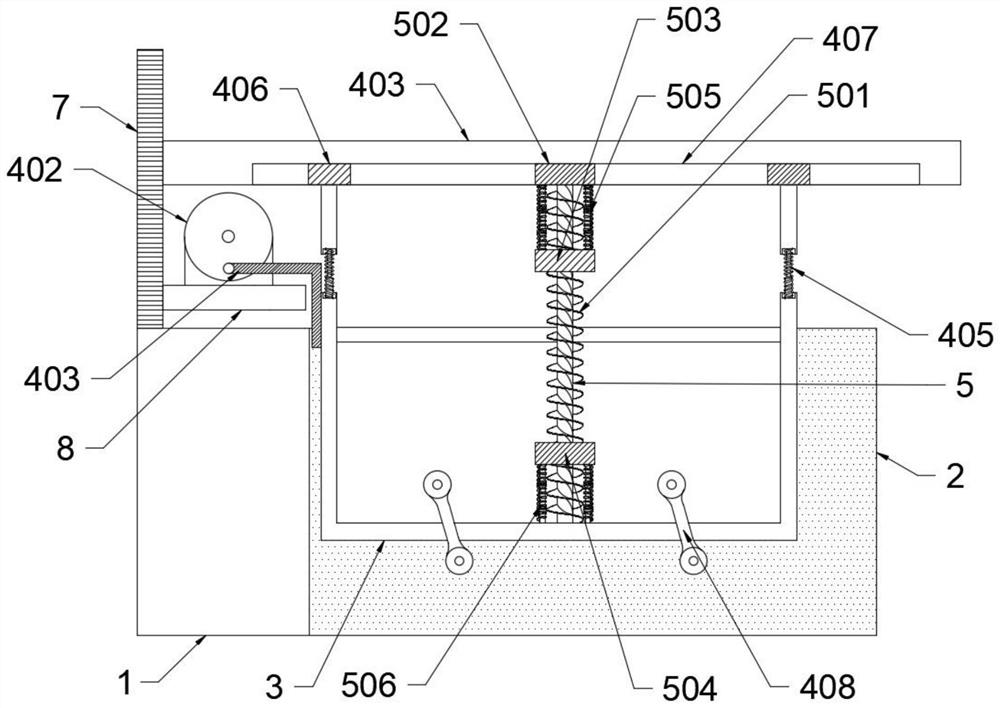

[0047] Such as Figure 1-5 As shown, the stirring assembly 5 includes a rotary blade rod 501, a second slide block 502, a first push block 503, a second push block 504, a second telescopic rod 505 and a third telescopic rod 506, and the quadrilateral rotating cylinder 901 is sleeved on the In the rotary vane rod 501, the top and bottom ends of the quadrilateral rotating cylinder 901 are detachably installed between the first push block 503 and the second push block 504, so that the first push block 503 and the second push block 504 cooperate , driving the quadrilateral rotating cylinder 901 to move up and down while realizing the rotation, increasing the fluidity of the cleaning liquid, so that the cleaning effect of the filter in the cleaning liquid is better. The inside is used to hold the cleaning liquid, which is convenient for cleaning the optical filter. The cleaning tank 2 is equipped with a cleaning basket 3, and the outside of the cleaning basket 3 is uniformly provid...

Embodiment 3

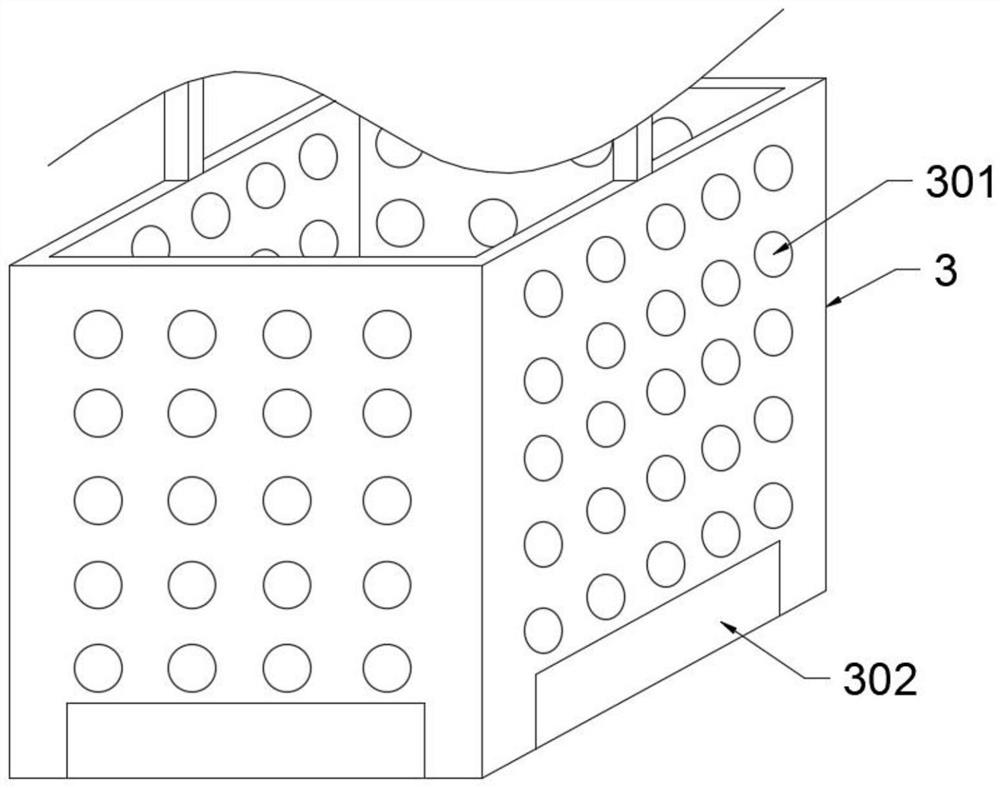

[0050] Such as Figure 1-5 As shown, the water pump 601 continuously filters the cleaning solution through the suction pipe 602 and the outlet pipe 603, the clamping assembly 9 moves up and down in the cleaning basket 3 and rotates, and the cleaned impurities are generated by the rotation of the clamping assembly 9 The vortex flow brings the impurities to the bottom of the washing basket 3, and the impurities are flushed into the filter water tank 604 through the water tank 302 by the water pump 601. The size of the water tank 302 is set to be large, so that the impurities can be washed to the filter water tank 604 in a short time In order to prevent impurities from being brought into the upper layer of the cleaning liquid by the rotation of the clamping assembly 9, the filter will be polluted twice, and the cleaning liquid will be transported to the cleaning tank 2 through the filter screen through the function of the filter water tank 604. 605 filters the impurities of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com