Equipment and method for recovering volatile organic compounds

A volatile organic compound and equipment technology, which is applied in the field of volatile organic compound recovery equipment, can solve the problems of complex equipment structure and processing process, low work efficiency, and many components, and achieve improved resource utilization, low cost, and high purification. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

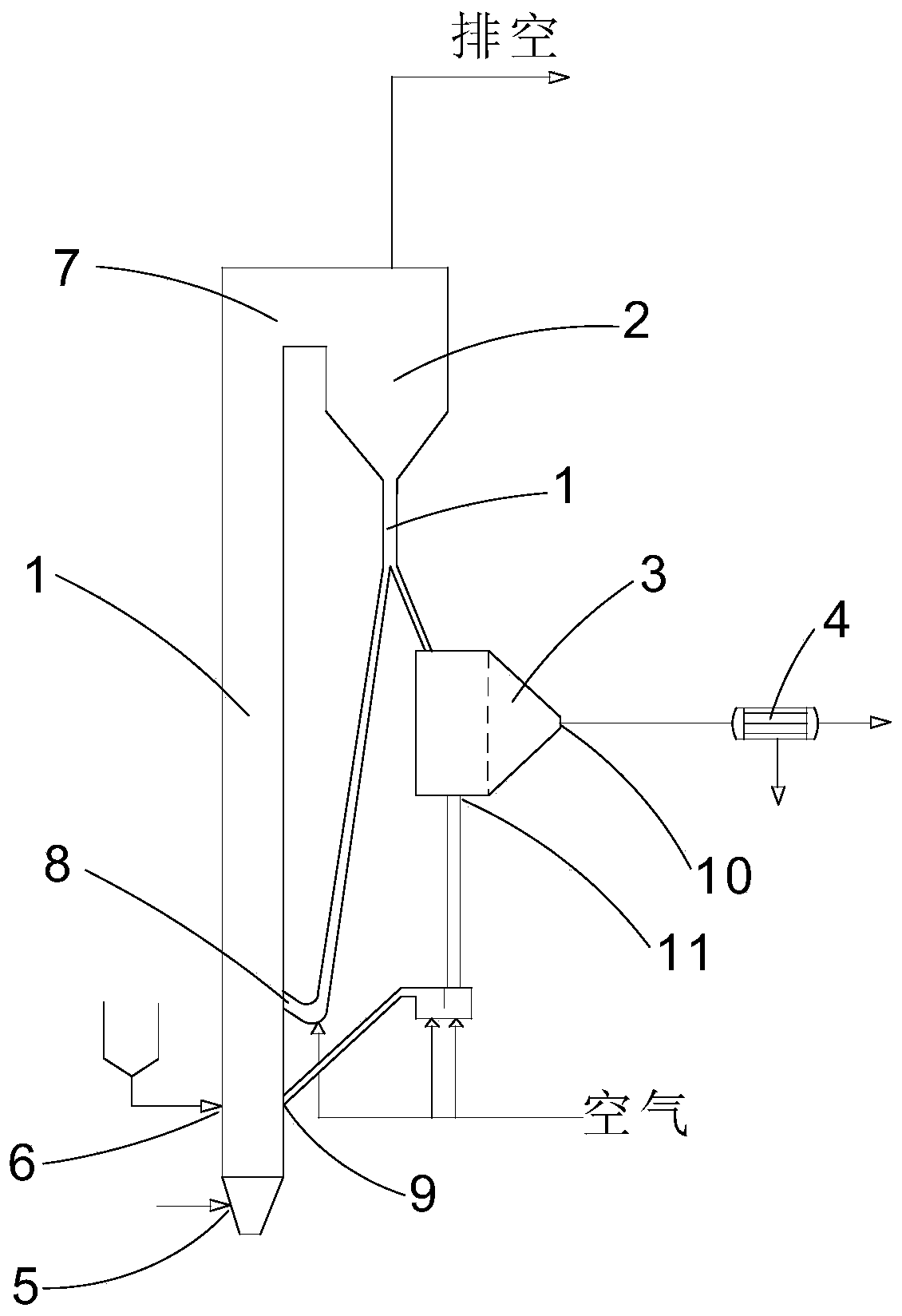

[0049] like figure 1 As shown, a device for recovering volatile organic compounds includes a circulating fluidized bed 1, a primary cyclone separator 2, a desorber 3 and a condenser 4; the circulating fluidized bed 1 is provided with a bottom inlet 5 and a lower inlet 6. The top outlet 7, the first lower return port 8 and the second lower return port 9, the bottom inlet 5 is used to input VOCs-containing gas, the lower inlet 6 is used to input adsorbent, the top outlet 7 is connected with the first stage The inlet of the cyclone separator 2 is connected, and the first lower return port 8 and the inlet of the desorber 3 are all connected with the solid outlet of the primary cyclone separator 2; the desorber 3 is provided with a first outlet 10 and a second outlet 11. The first outlet 10 communicates with the condenser 4, and the second outlet 11 communicates with the second lower return port 9.

[0050] Industrial emissions containing 500mg / m 3 Toluene gas, exhaust gas temper...

Embodiment 2

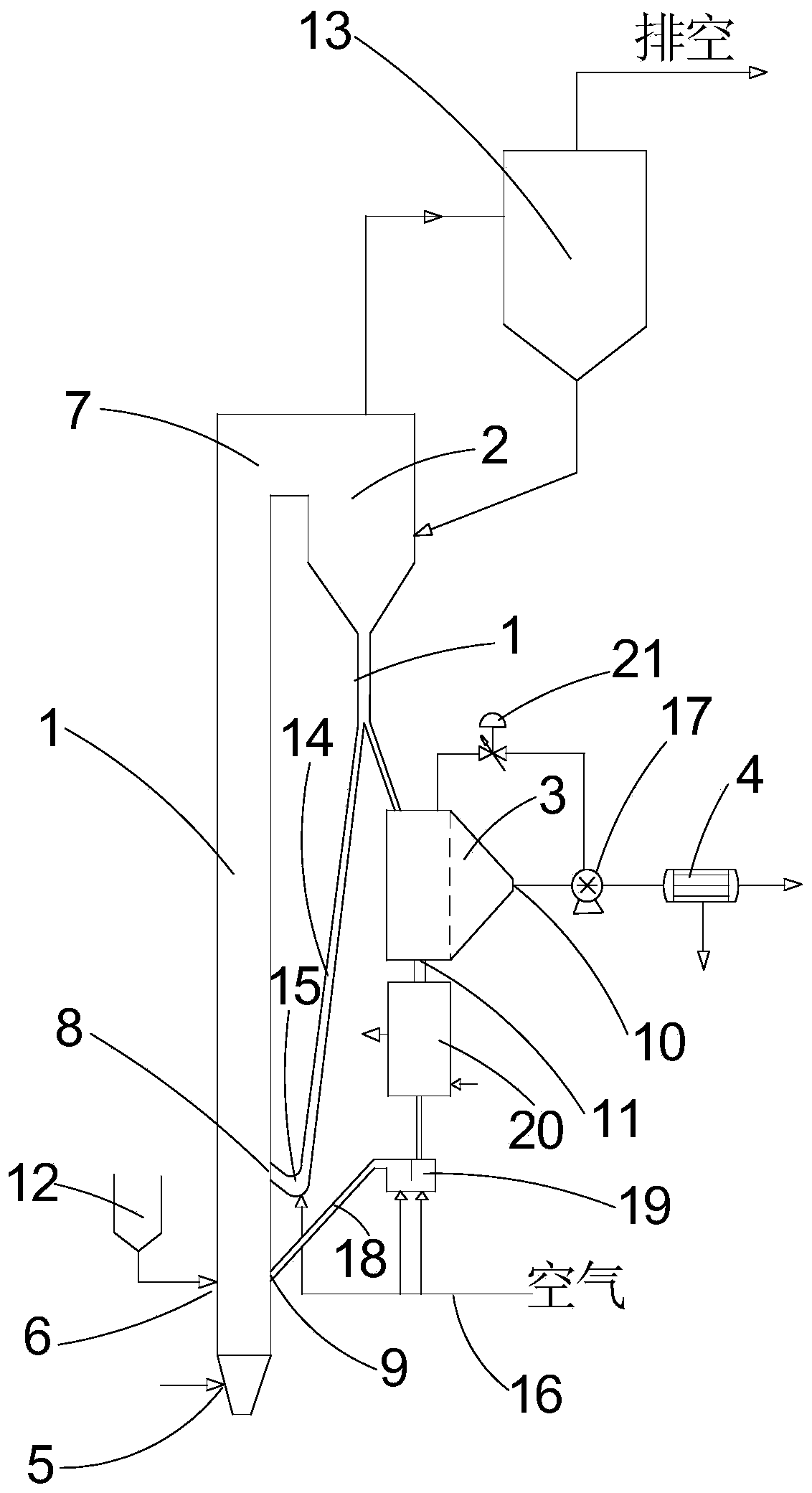

[0052] like figure 2 As shown, a device for recovering volatile organic compounds includes a circulating fluidized bed 1, a primary cyclone separator 2, a desorber 3 and a condenser 4; the circulating fluidized bed 1 is provided with a bottom inlet 5 and a lower inlet 6. The top outlet 7, the first lower material return port 8 and the second lower material return port 9, the bottom inlet 5 is used to input VOCs-containing gas, the lower material inlet 6 and the adsorbent storage tank 12 (considering the wear of the adsorbent loss, the adsorbent storage tank 12 regularly replenishes fresh adsorbent to maintain the system circulation) is communicated for inputting the adsorbent, and the top outlet 7 is communicated with the inlet of the primary cyclone separator 2; the gas outlet of the primary cyclone separator 2 is connected with the The inlet of the secondary cyclone separator 13 is communicated, the solid outlet of the secondary cyclone separator 13 is communicated with the...

Embodiment 3

[0055] The equipment for recovering volatile organic compounds is the same as in Example 2.

[0056] Divinyl styrene ethyl spherical resin with a particle size of 0.6 mm is used as an adsorbent to purify industrial emissions containing 200 mg / m 3 The exhaust gas of butyl acetate, the temperature is 25°C, the relative humidity is 60%, enters from the bottom of the circulating fluidized bed 1, and the air volume is 25000m 3 / h. The flow ratio of the first return pipe 14 and the desorber 3 is adjusted to 5:1, and the temperature of the desorber 3 is 150°C. The desorbed butyl acetate gas enters the condenser 4 under the action of the induced draft fan 17 and is condensed into a liquid state without producing noncondensables. Measured by gas chromatography, the butyl acetate content in the evacuated gas above the secondary cyclone separator 13 is lower than 10 mg / m 3 , The purification efficiency of butyl acetate reaches more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com