Arc panel and straight plate border line setting device for steam oven

A technology for steaming ovens and boundary lines, which is applied in the field of setting devices for arc panels and straight panels for steaming ovens. It can solve problems such as cracks, low welding strength of straight panels on arc panels, and inability to fully fit and contact. The effect of increasing welding strength and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

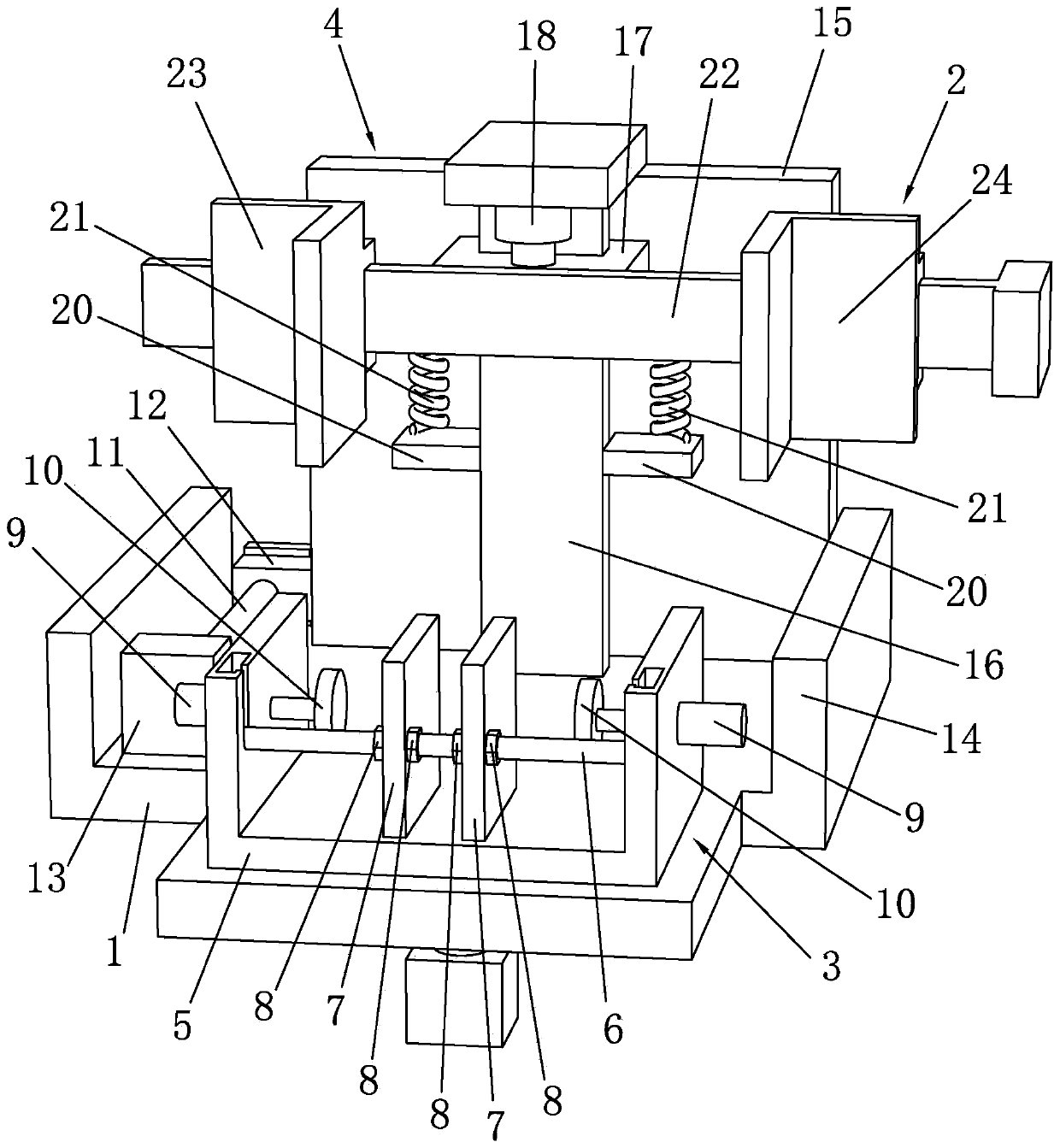

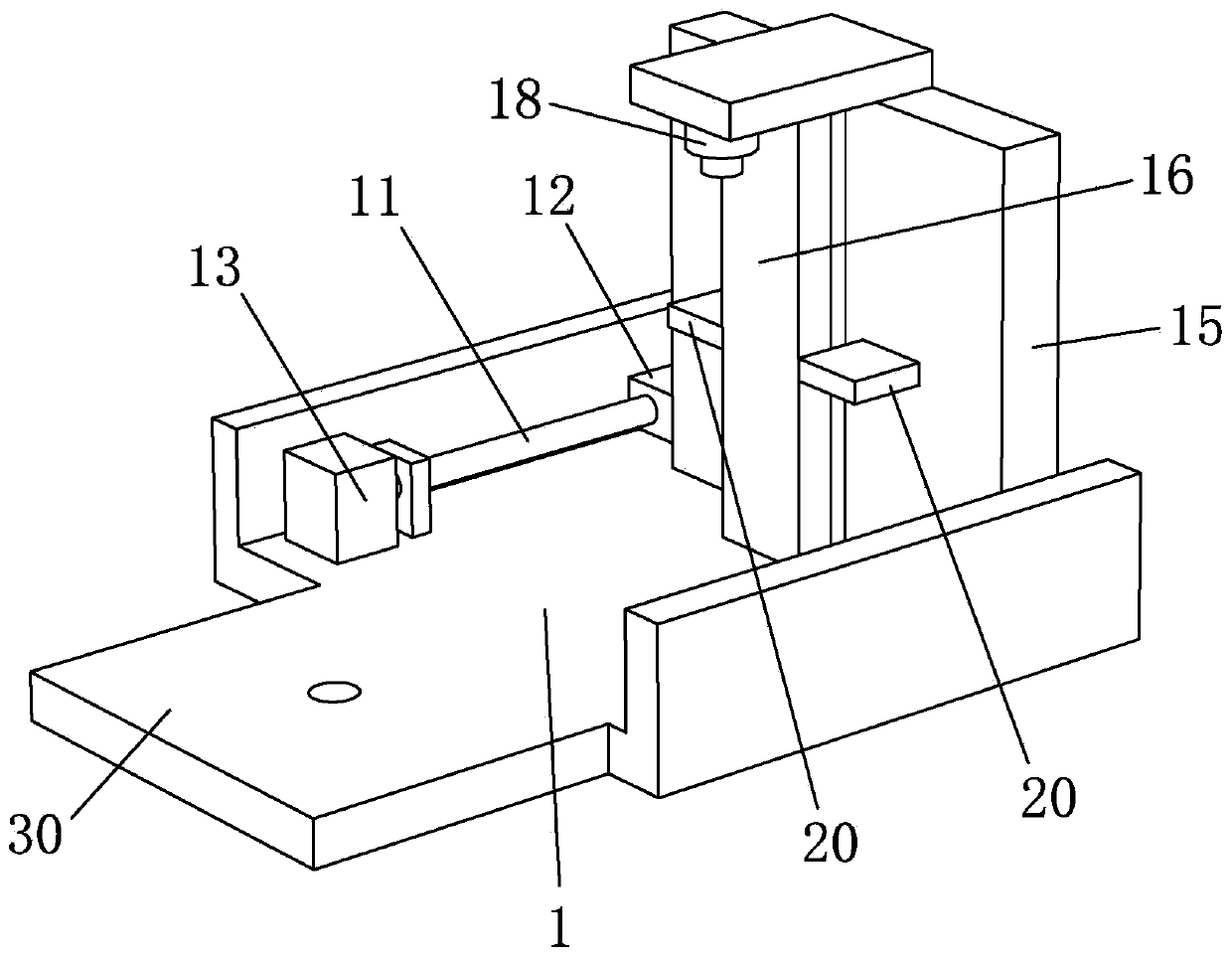

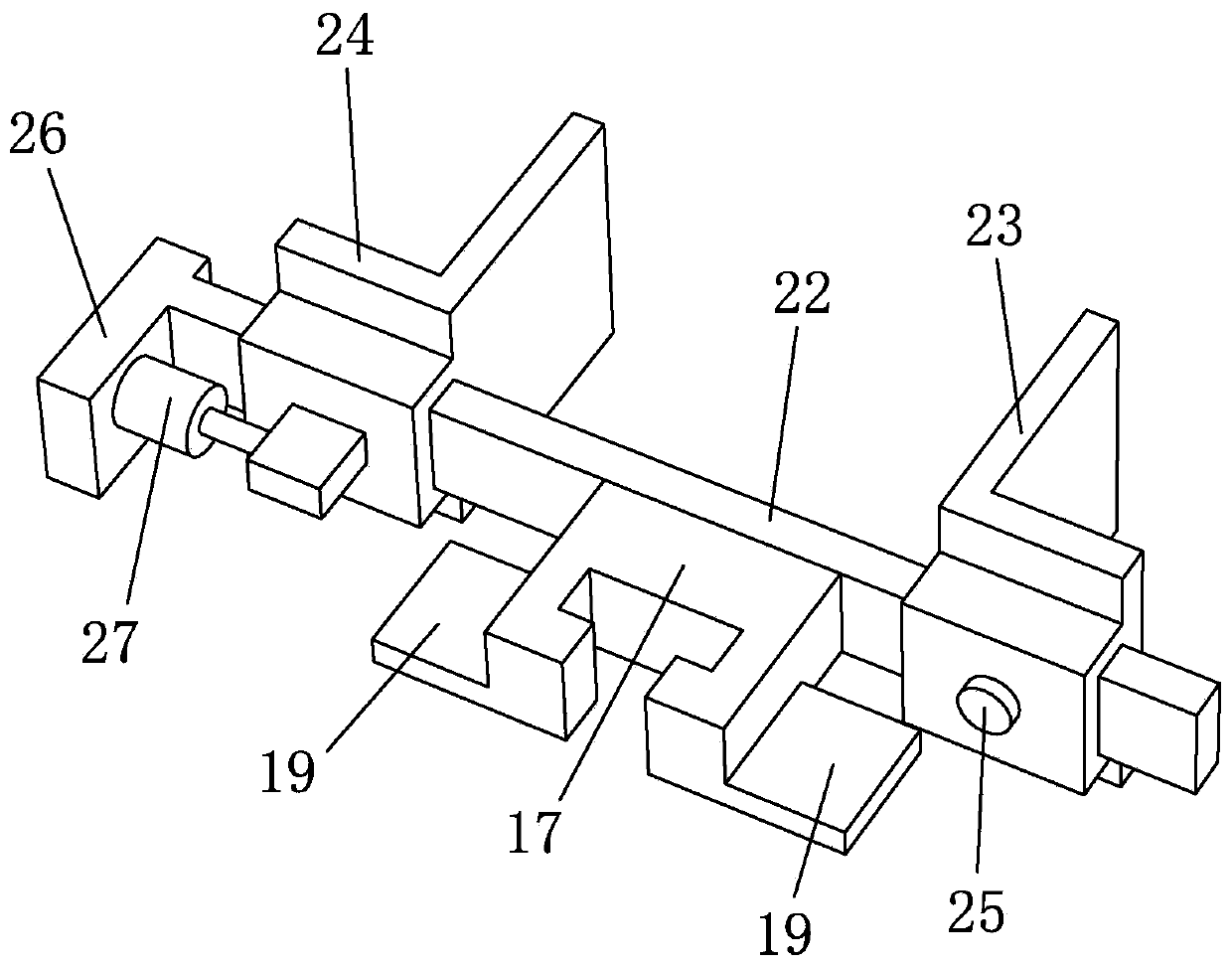

[0036] Such as Figure 1 to Figure 10 As shown, it is a device for setting the boundary line between arc panels and straight panels for steaming ovens of the present invention, including a workbench 1, a clamping device 2 for installing arc panels 33 and a loading device 3 for installing straight panels 34, and the clamping device 2 is located above the loading device 3. The worktable 1 is provided with an adjustment mechanism 4 , the adjustment mechanism 4 moves along the length direction of the workbench 1 , and the clamping device 2 moves along the height direction of the adjustment mechanism 4 .

[0037] The loading device 3 includes a loading casing 5, the loading casing 5 is provided with a threaded rod 6, the threaded rod 6 is provided with two loading plates 7, the threaded rod 6 is provided with an adjusting nut 8, and each loading plate 7 is provided with two corresponding Adjustment nut 8. Both sides of the loading shell 5 are provided with a first air cylinder 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com