Brazed plate heat exchanger fully-automatic sheet making system

A heat exchanger, fully automatic technology, applied in manufacturing tools, heat exchange equipment, other manufacturing equipment/tools, etc., can solve problems such as lack of synergy, unfavorable enterprise production capacity, and inability to smoothly reclaim materials, and achieve large-scale convenience. The effect of industrialized production, increasing physical blocking and induction, and improving the efficiency of demolding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

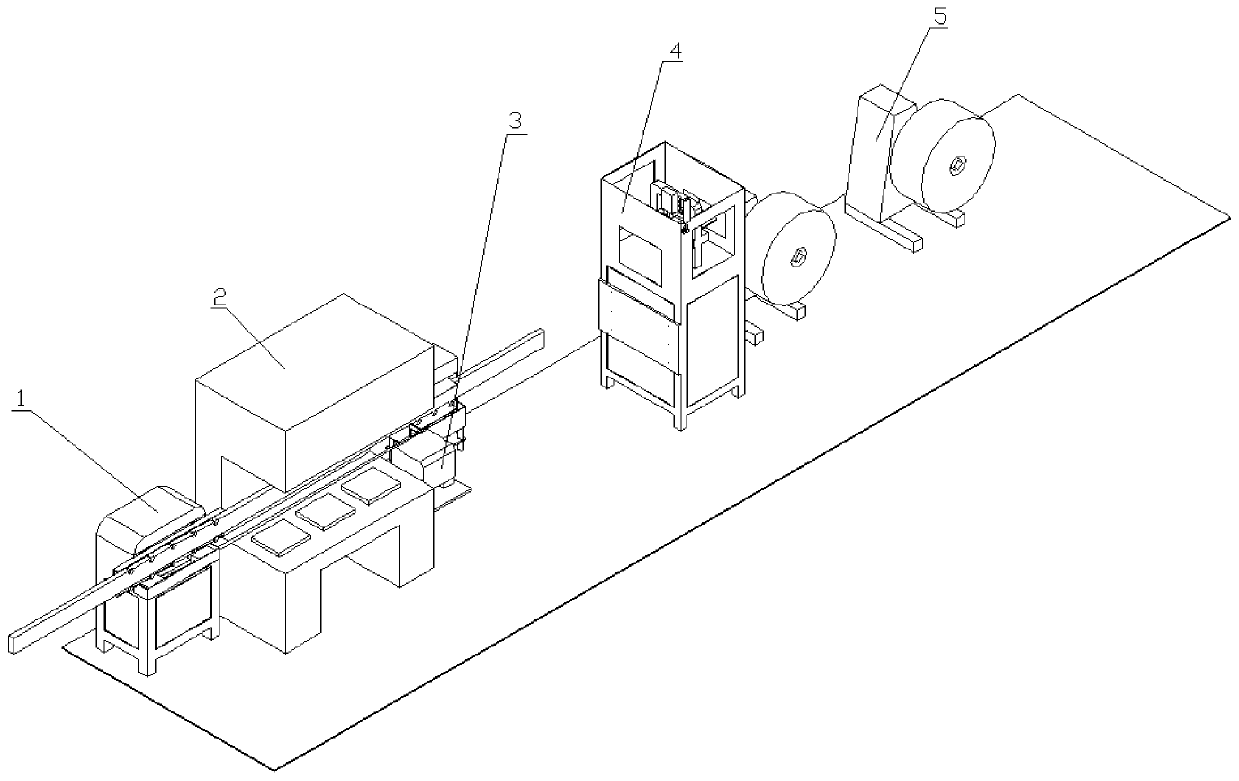

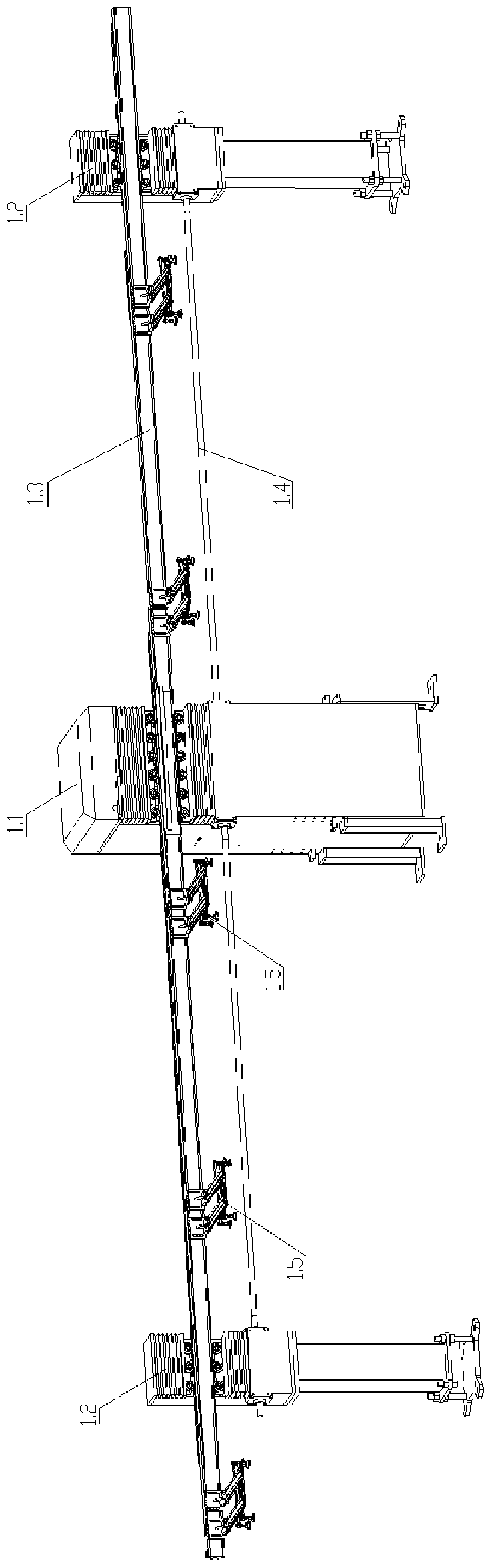

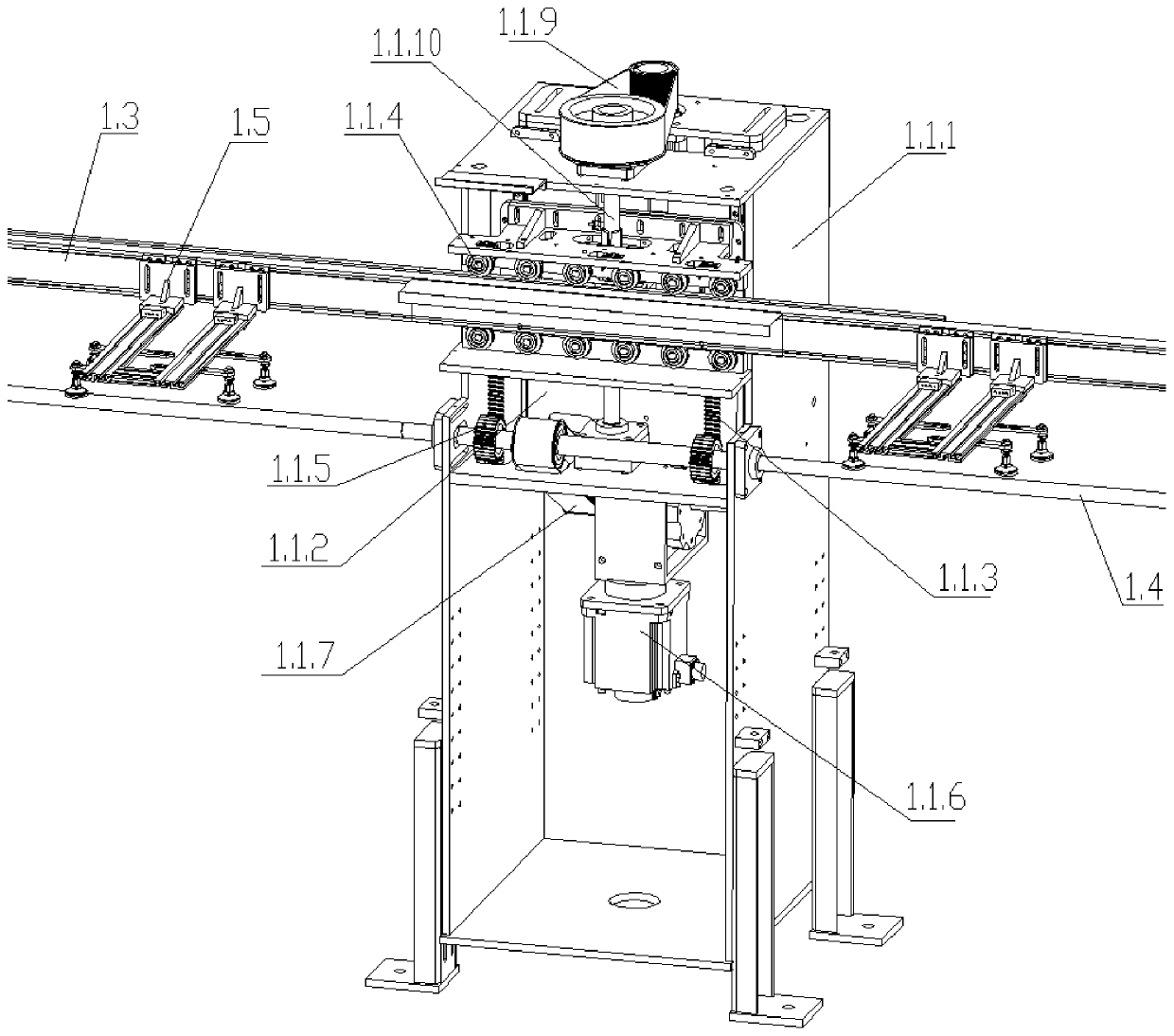

[0052] see Figure 1-11 , the present invention relates to a fully automatic sheet-making system for brazed plate heat exchangers, the system includes a manipulator assembly 1, a stamping and pressing device 2, an automatic length-fixing device 3, an intermediate frequency spot welding device 4 and two unwinding device 5;

[0053] Two unwinding devices 5 are respectively wound with stainless steel plate and copper foil, and the combined stainless steel plate and copper foil are guided into the automatic length-fixing device 3 after passing through the intermediate frequency spot welding device 4, and the manipulator assembly 1 is located between the stamping and pressing device 2 and the automatic Beside the fixed-length device 3;

[0054] The intermediate frequency spot welding device 4 includes an upper fixed plate 4.1, horizontal guide rails 4.7 are installed on both sides of the upper fixed plate 4.1, and the top surface of the upper wedge block 4.8 is slidingly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com