Digital twin driven numerically-controlled machine tool cutter monitoring system

A monitoring system and cutting tool technology, which is applied in the fields of electronic engineering and computer science, can solve problems such as the inability to accurately grasp the wear status of cutting tools, and achieve the effects of rich types, avoiding broken and blunt knives, and comprehensive information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

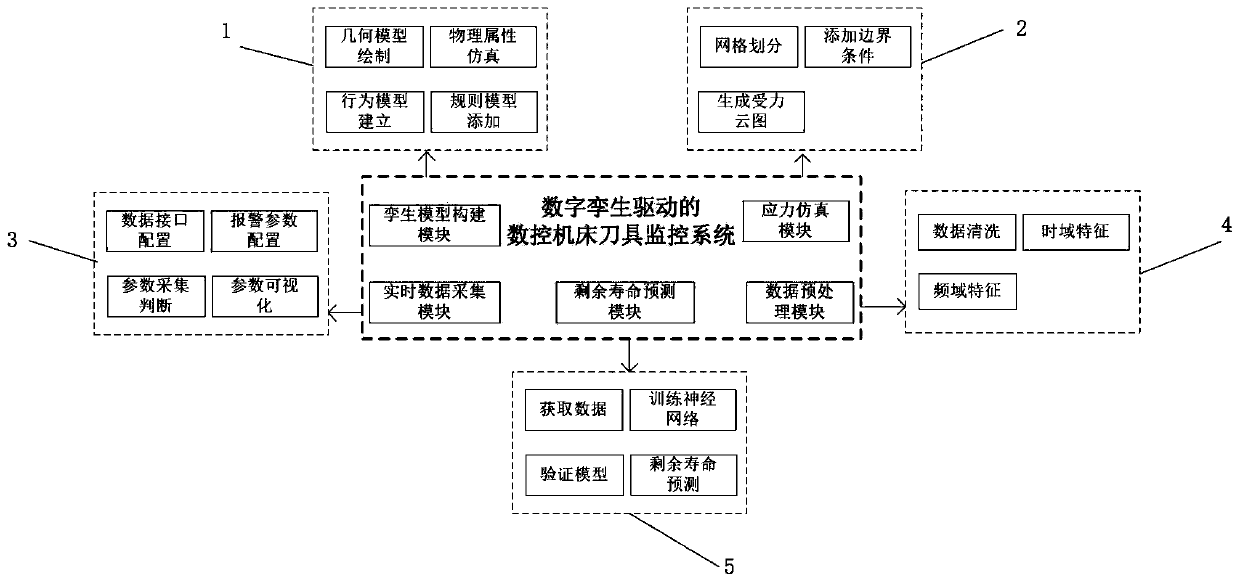

[0043] The invention relates to a digital twin-driven CNC machine tool tool monitoring system. The system aims at the problem that the tool wear state of the CNC machine tool cannot be accurately grasped during the cutting process of the CNC machine tool, and uses digital twin technology to analyze and simulate the data of the tool itself and the entire cutting process. Simulation, and ultimately improve the efficiency of tool control.

[0044] The structural diagram of the present invention is as figure 1 As shown, the specific implementation is as follows:

[0045] (1) figure 1 The twin model building block 1 in is implemented as follows:

[0046] The geometric model drawing module uses software tools to establish the geometric model of the tool, which reflects its shape, size, structural composition and assembly relationship, and obtains the geometric m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com