3D printer coaxial nozzle and 3D printer with the same

A 3D printer and coaxial nozzle technology, applied in the field of 3D printing, can solve the problem of no temperature control device and the inability to achieve temperature control of different materials, and achieve the effect of maintaining characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

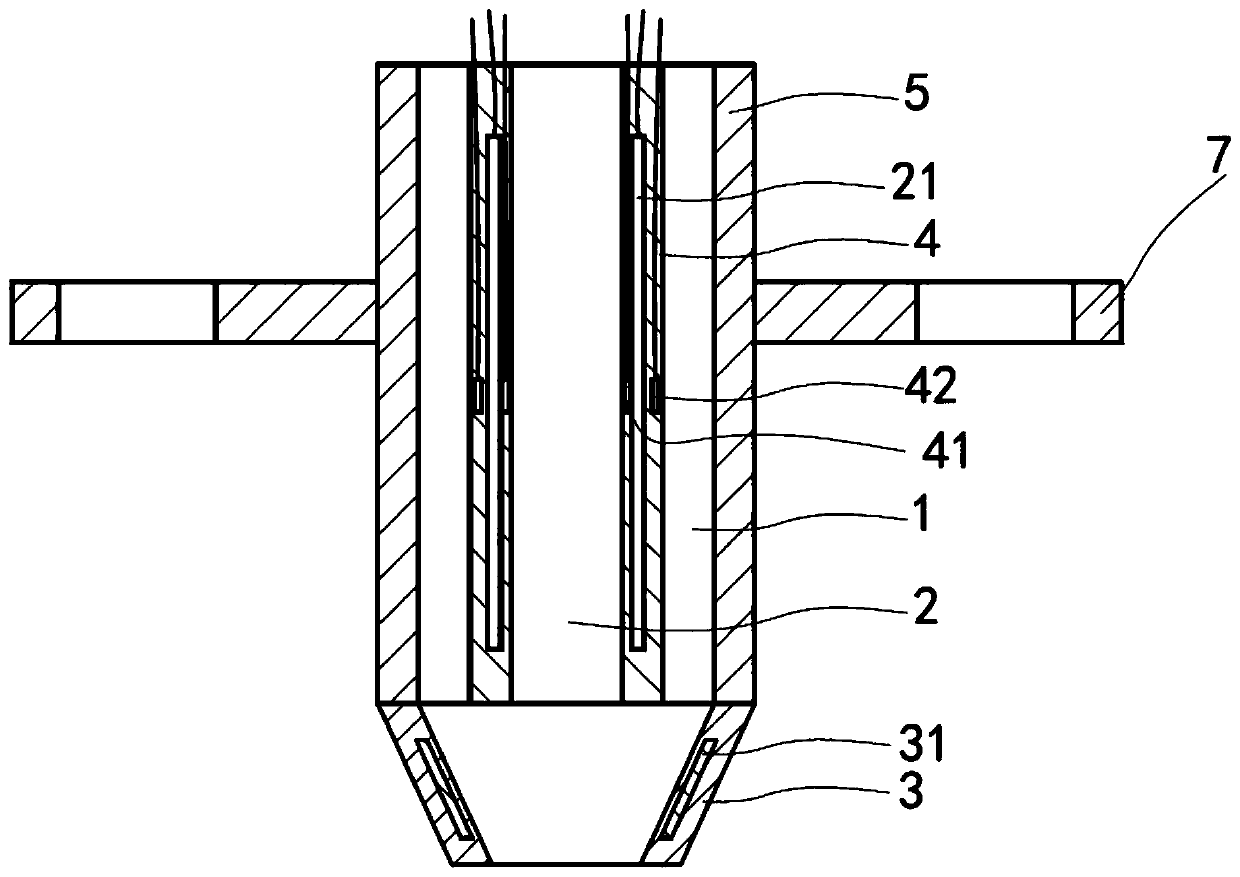

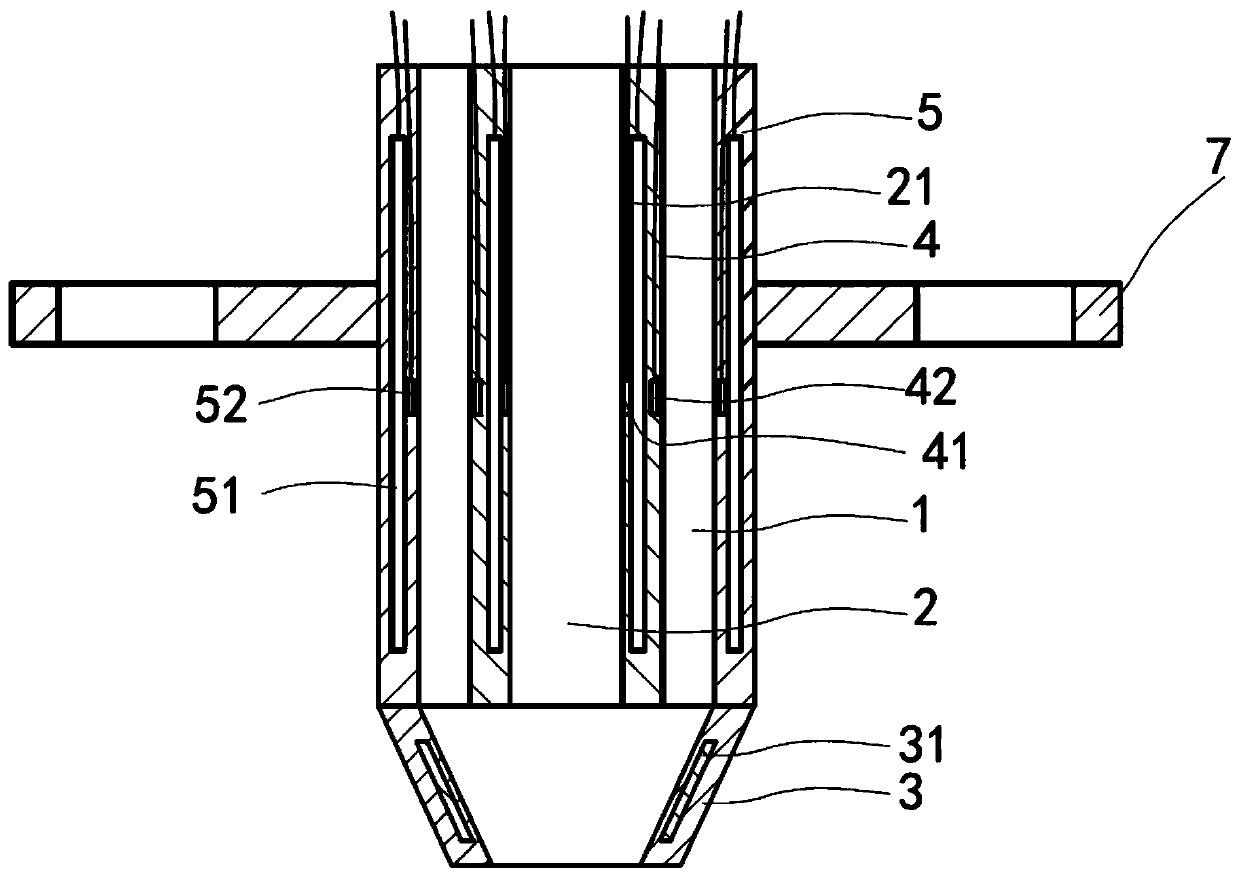

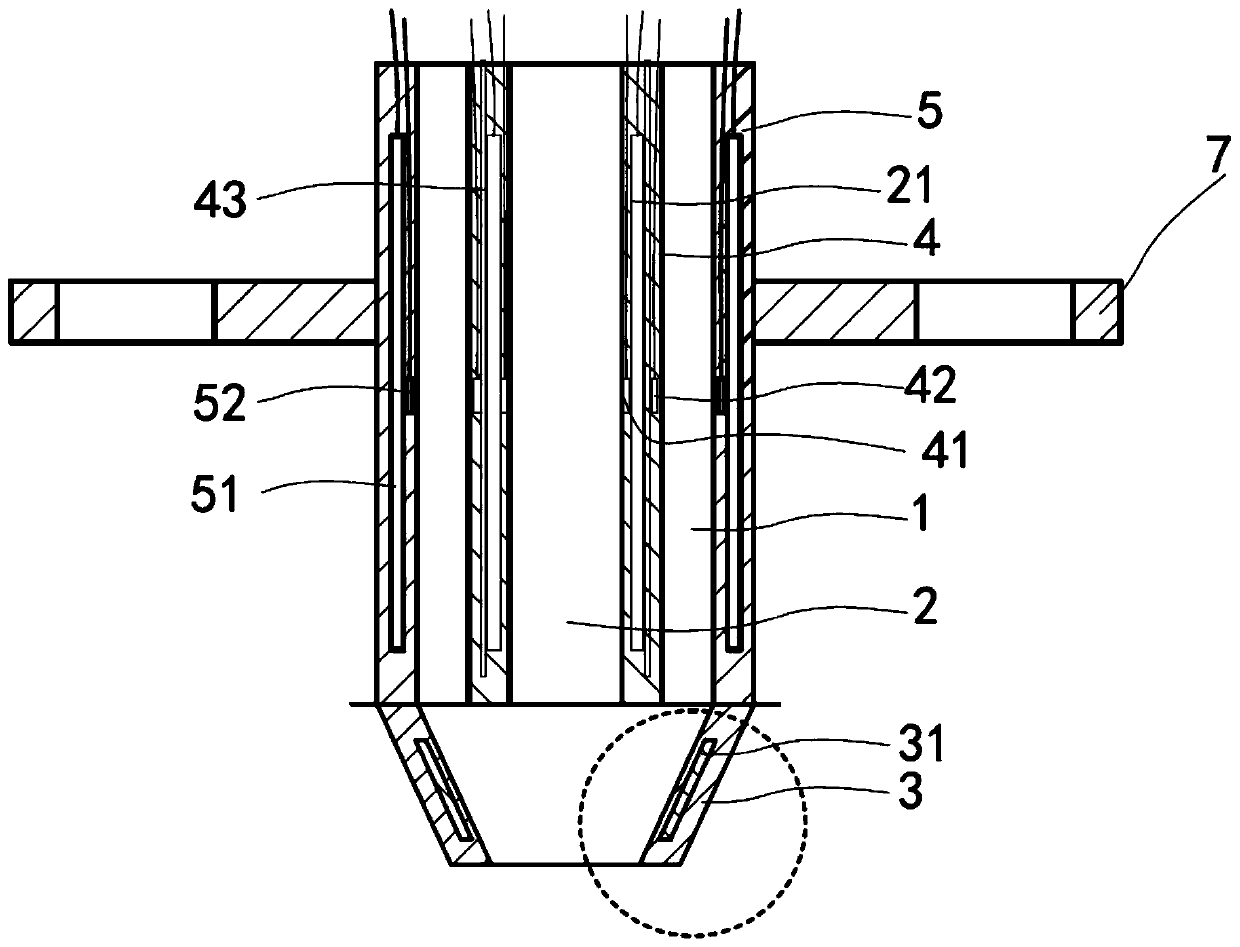

[0046] Embodiment of the present invention one 3D printer coaxial spray head sectional view see figure 1 .

[0047]A 3D printer coaxial nozzle, comprising an outer tube 1, an inner tube 2 and a nozzle 3, the inner tube 2 is nested in the outer tube 1, the nozzle is arranged at the lower end of the outer tube 1, and the first tube wall 4 of the inner tube 2 is provided with In the semiconductor refrigerator 21, a first temperature sensor 41 is embedded in the inner side of the first tube wall 4, and a second temperature sensor 42 is embedded in the outer side of the first tube wall 4. The semiconductor refrigerator 21 is connected with a power supply device, and is connected with the first A temperature sensor 41 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com