Auxiliary shaping technology method for completely cured aramid fiber honeycombs

A technology of aramid honeycomb and process method, which is applied to other household appliances, household appliances, household components, etc., which can solve the problems of high resilience of fully cured honeycomb, poor secondary molding effect, and inability to effectively shape the shape, so as to reduce honeycomb deterioration risk, reduce storage costs, and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

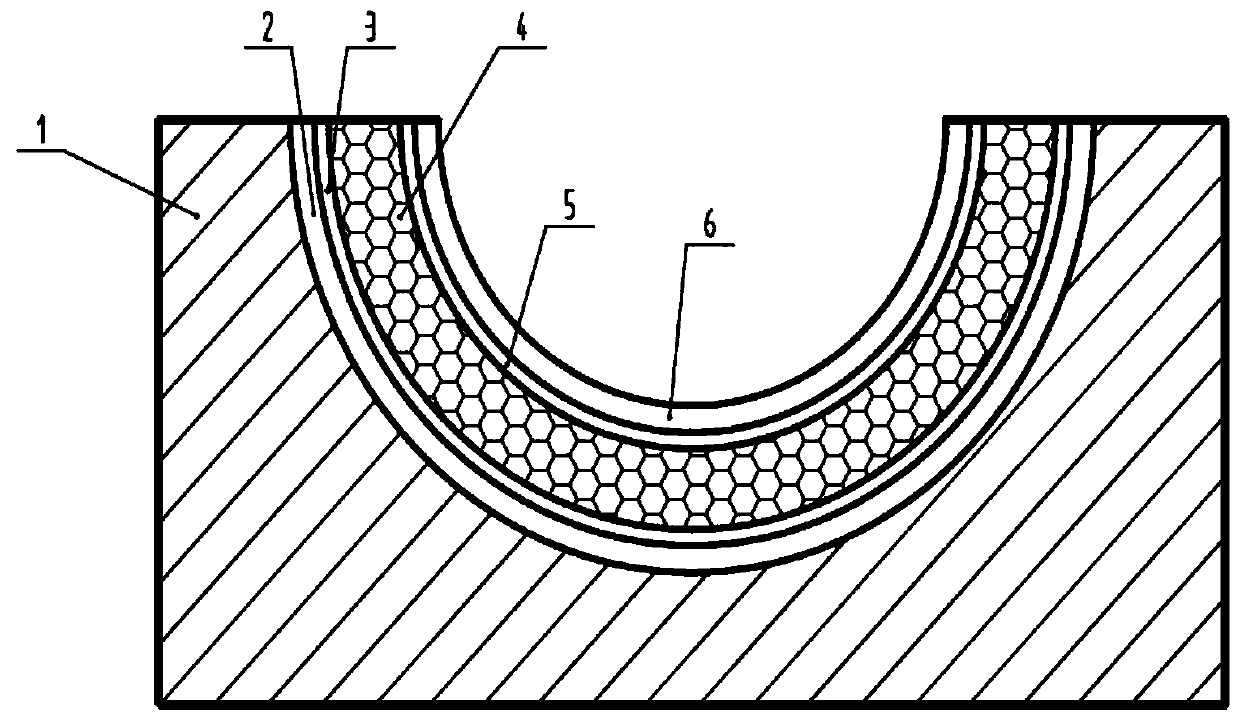

[0023] Below, combine figure 1 , the present invention will be further described.

[0024] A process method for fully curing aramid honeycomb assisted shaping, comprising steps:

[0025] S1. Prepare a mold, preset a semicircular configuration with curvature, and open a required configuration groove on the surface of the mold, and the surface shape of the configuration groove is consistent with the semicircular configuration;

[0026] S2. Prepare the front skin, pave the composite material prepreg in the configuration groove, and use an autoclave to perform hot pressing after paving to obtain the front skin;

[0027] S3. Prepare the sandwich core and cut the fully cured honeycomb. After cutting, the honeycomb is just completely fitted into the configuration groove, and the vertical pressure is always provided on the surface of the fully cured honeycomb, and the fully cured honeycomb is continuously pressed. In the configuration groove, the bottom surface of the honeycomb is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com