Elastic Clay Buffer for Metro Vehicles

A technology of elastic clay and buffer, which is applied in the direction of buffer, railway car body parts, solid shock absorber, etc., can solve the problems of steep characteristic curve, high static impedance, high initial resistance, etc., to meet performance requirements, The effect of high sealing reliability and low initial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

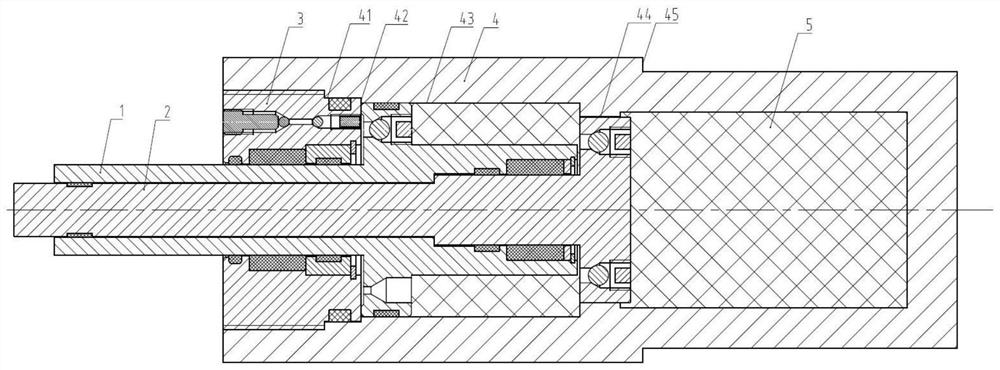

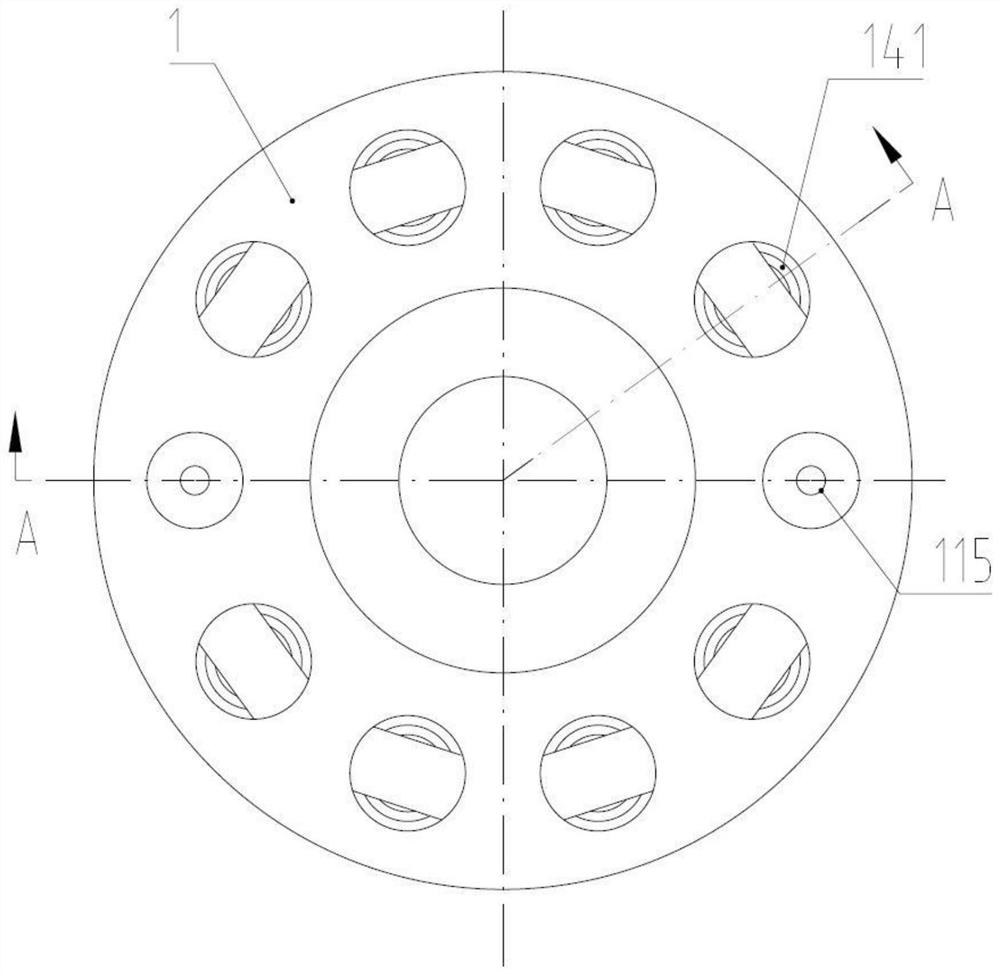

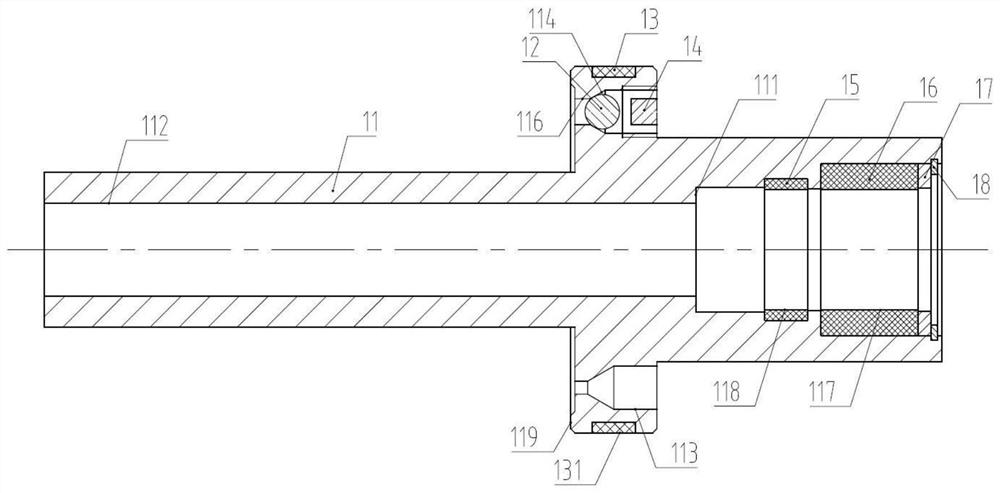

[0032] refer to figure 1 As shown, the patented product of the present invention includes an outer piston rod component 1 coaxially installed together, an inner piston rod component 2, a cylinder head component 3, a cylinder body 4 and an elastic cement material 5 that is pressure-packed inside the cylinder body 4 . A damping slit flow 44 is set between the inner piston rod component 2 and the cylinder body 4, the fourth guide belt 13 installed on the outer piston rod component 1 slides and fits with the inner wall 43 of the cylinder body 4, and the cylinder head component 3 Axial positioning is realized with the cylinder body 4 through the positioning surface 42. The radial positioning of the cylinder head component 3 and the cylinder body 4 is realized through the positioning surface 41. The outer diameter of the cylinder body 4 is provided with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com