Garbage compressing and packaging integrated machine

A technology of garbage compression and integrated machine, which is applied in the direction of press, garbage conveying, garbage collection, etc., can solve the problems of high compression stability, inability to pack garbage, etc., so as to reduce the occupied area, be less prone to failure, and reduce garbage removal and transportation. the effect of the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

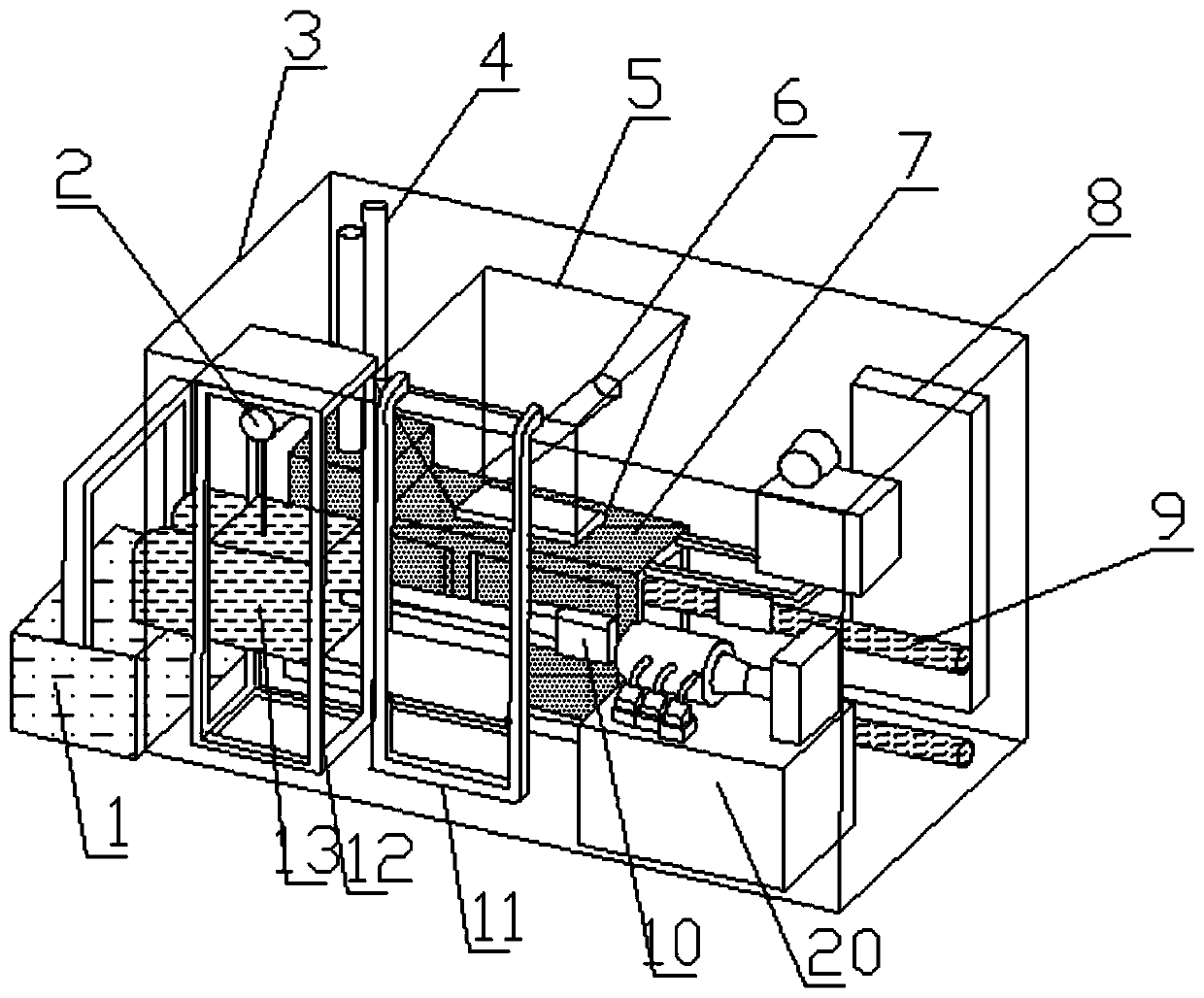

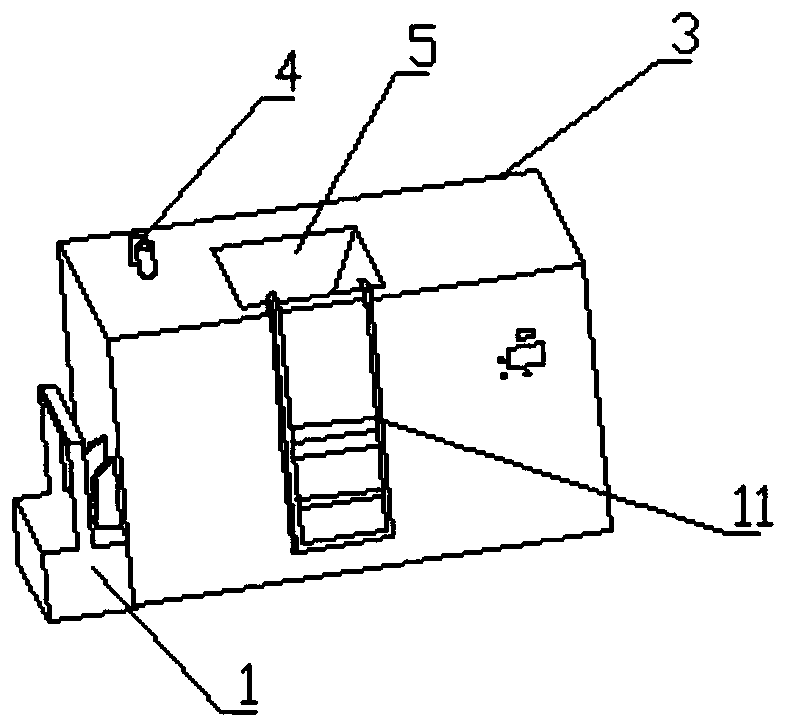

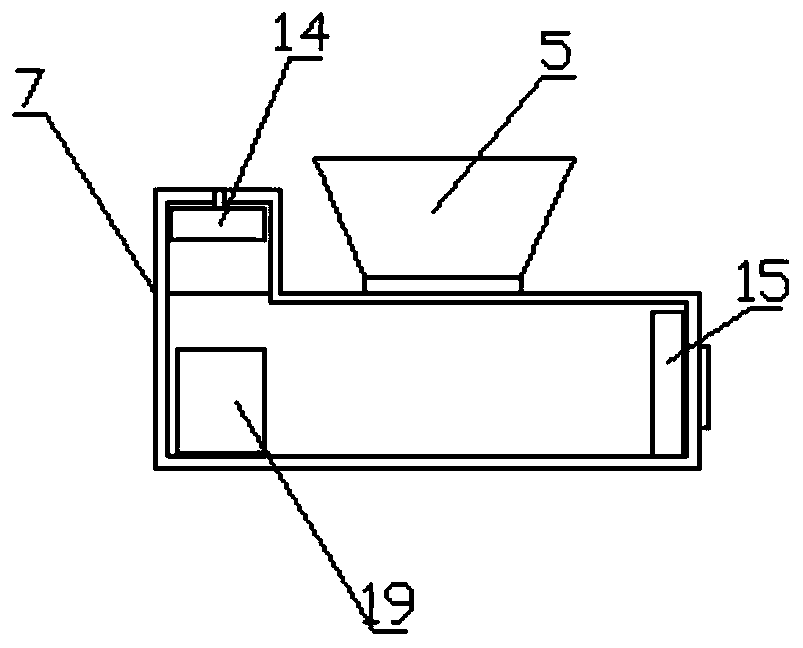

[0026] Such as Figure 1-5 As shown, a garbage compression and packaging machine includes a casing 3, a baler 1 and a compression box 7, one side of the casing 3 is provided with a hoist 11 through a mounting frame, and one end of the casing 3 is connected by a bolt A baler 1 is installed, and a compression box 7 is installed through bolts in the casing 3, and a discharge hydraulic cylinder 6 is installed on one side of the compression box 7 through a mounting seat, and one end of the compression box 7 is set through a fixing seat There is a horizontal hydraulic cylinder 9, one end of the compression box 7 is equipped with a discharge lifting frame 12 through a bolt, and the inner top of the discharge lifting frame 12 is provided with a hoist 2 through a limit plate, and the lower end of the hoist 2 is provided with a discharge Material box 13, the inner side of the bracket of the discharge lifting frame 12 is embedded with a slide groove 16 through screws, and the two ends of...

Embodiment 2

[0038] Such as Figure 1-5As shown, a garbage compression and packaging machine includes a casing 3, a baler 1 and a compression box 7, one side of the casing 3 is provided with a hoist 11 through a mounting frame, and one end of the casing 3 is connected by a bolt A baler 1 is installed, and a compression box 7 is installed through bolts in the casing 3, and a discharge hydraulic cylinder 6 is installed on one side of the compression box 7 through a mounting seat, and one end of the compression box 7 is set through a fixing seat There is a horizontal hydraulic cylinder 9, one end of the compression box 7 is equipped with a discharge lifting frame 12 through a bolt, and the inner top of the discharge lifting frame 12 is provided with a hoist 2 through a limit plate, and the lower end of the hoist 2 is provided with a discharge Material box 13, the inner side of the bracket of the discharge lifting frame 12 is embedded with a slide groove 16 through screws, and the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com