Low-silicon transfer silica gel pressure-sensitive adhesive protective film

A silicone pressure-sensitive adhesive protective film and transfer layer technology, used in adhesives, epoxy resin adhesives, printing and other directions, can solve problems such as silicon pollution, and achieve strong ink adhesion, excellent adhesion, and good transfer firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

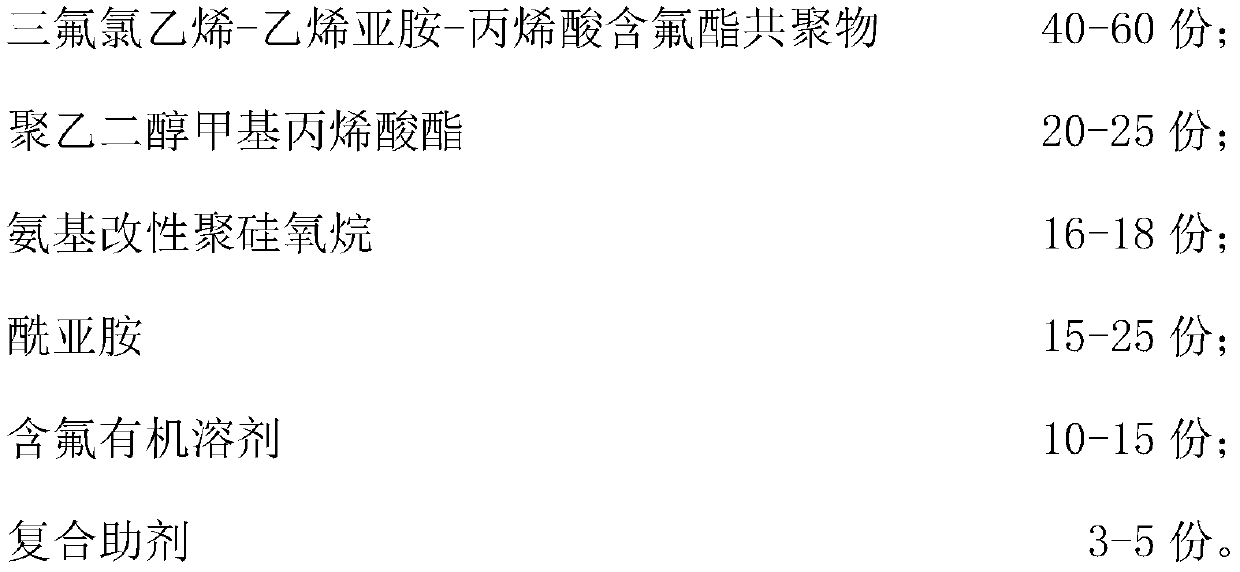

[0021] A low-silicon transfer silicone pressure-sensitive adhesive protective film, the low-silicon transfer silicone pressure-sensitive adhesive protective film sequentially includes a low-silicon transfer layer, an adhesive layer, and a substrate layer from top to bottom, wherein the low-silicon transfer layer is by weight Contains the following ingredients:

[0022]

[0023] Among them, the preparation method of chlorotrifluoroethylene-ethyleneimine-acrylic acid fluorine-containing ester copolymer is: add 100 parts by weight of water and 150 parts by weight of fluorine-containing organic solvent to the autoclave under vacuum conditions, and then add 75 parts by weight Acrylic fluorine-containing ester monomer, 40 parts by weight of imide monomer and 1.2 parts by weight of molecular weight regulator tetrachloromethane, while stirring to raise the temperature to 60 ° C, then import 25 parts by weight of chlorotrifluoroethylene monomer, adjust After the polymerization press...

Embodiment 2

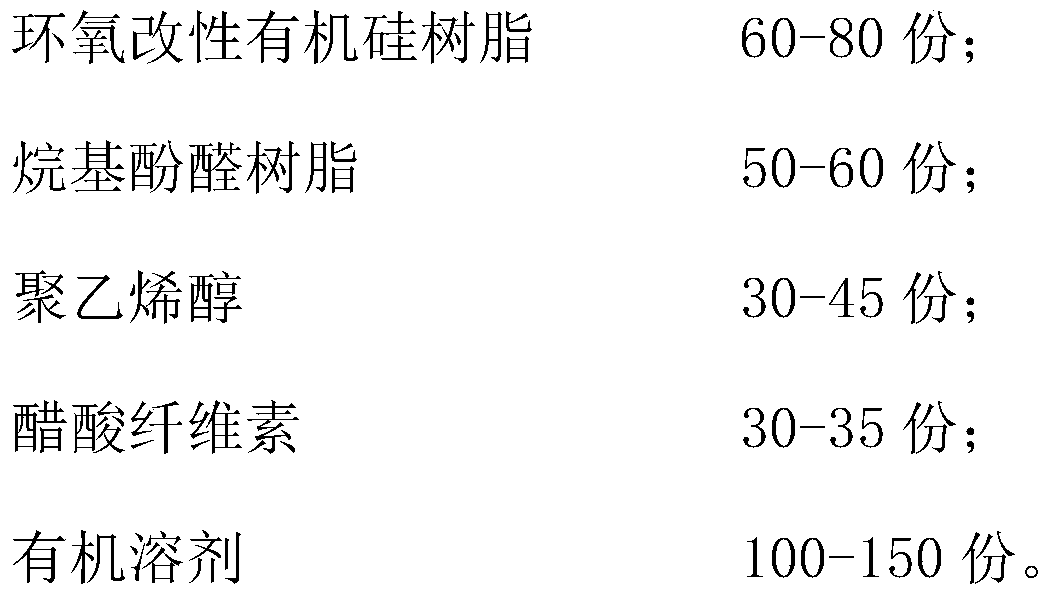

[0031] A low-silicon transfer silicone pressure-sensitive adhesive protective film, the low-silicon transfer silicone pressure-sensitive adhesive protective film sequentially includes a low-silicon transfer layer, an adhesive layer, and a substrate layer from top to bottom, wherein the low-silicon transfer layer includes by weight The following ingredients:

[0032]

[0033]

[0034] Among them, the preparation method of chlorotrifluoroethylene-ethyleneimine-acrylic acid fluorine-containing ester copolymer is: add 100 parts by weight of water and 150 parts by weight of fluorine-containing organic solvent to the autoclave under vacuum conditions, and then add 75 parts by weight Acrylic fluorine-containing ester monomer, 40 parts by weight of imide monomer and 1.2 parts by weight of molecular weight regulator tetrachloromethane, while stirring to raise the temperature to 60 ° C, then import 25 parts by weight of chlorotrifluoroethylene monomer, adjust After the polymerizat...

Embodiment 3

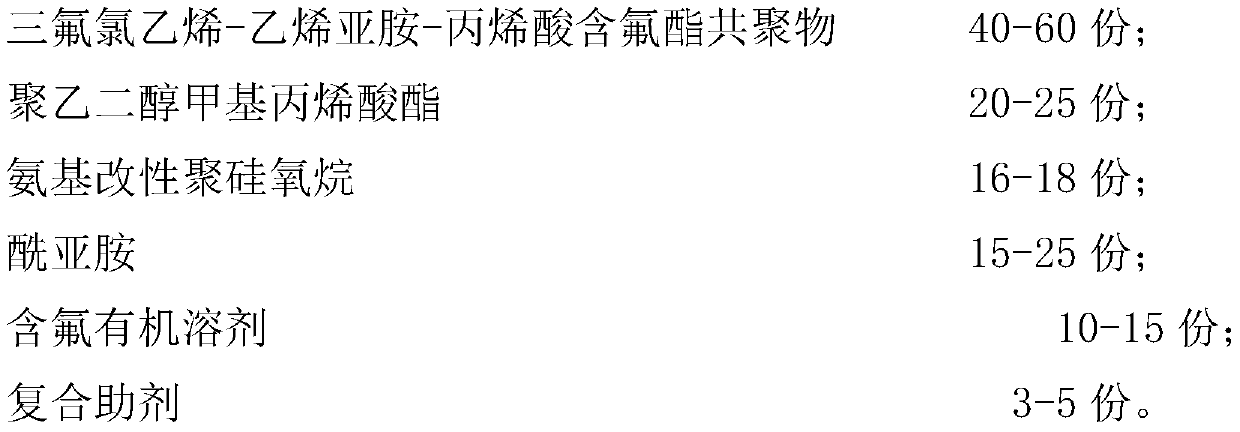

[0042] The raw materials and process of this embodiment are basically the same as those of Embodiment 1, the only difference is that the low-silicon transfer layer includes the following components in parts by weight:

[0043]

[0044]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap