Pressure-controlled flat plating equipment for base ring

A pedestal ring and pedestal technology, used in electrolytic components, electrolytic processes, circuits, etc., can solve the problems of high rework rate, uneven thickness and unevenness of welding marks, and achieve the effect of reducing rework rate and optimizing screening process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] as attached figure 1 to attach Figure 8 Shown:

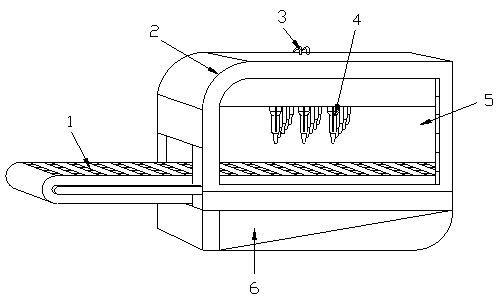

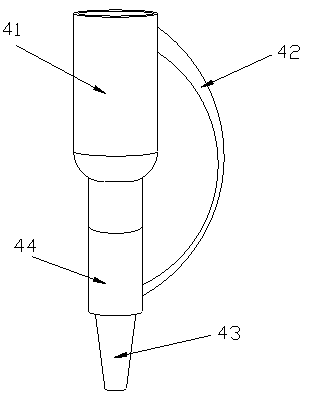

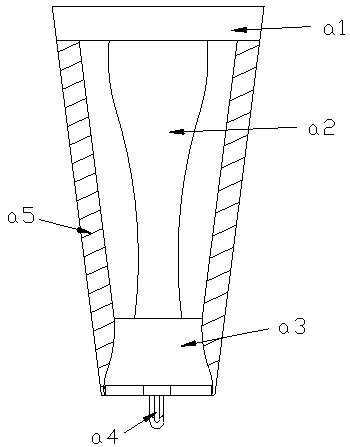

[0028] The invention provides a base circle control pressure flat plating equipment, its structure includes a conveyor belt 1, a base circle electroplating machine 2, an electroplating solution input pipe 3, a base circle control pressure flat plating device 4, a transparent protective baffle 5, a base 6. The conveyor belt 1 is movably connected with the base ring electroplating machine 2, the electroplating solution input pipe 3 is embedded in the top of the base ring electroplating machine 2 and fixedly connected with the base ring control pressure flat plating device 4, and the transparent protection The baffle plate 5 is installed on the positive end face of the base ring electroplating machine 2 by embedding, the top of the base 6 is welded to the bottom end of the base ring electroplating machine 2, and the base ring control pressure flat plating device 4 includes a fixed plating Liquid cylinder 41, conductive w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com