Roadbed and method for controlling differential settlement of road-bridge transition section of high-speed railway

A technology for high-speed railways and transition sections, which is applied in the field of foundation treatment and high-speed railway subgrades. It can solve problems such as difficulty in rolling subgrade fillers in place, shortage of graded crushed stone materials, and increased foundation settlement, so as to increase driving safety, Good self-compactness and small foundation disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

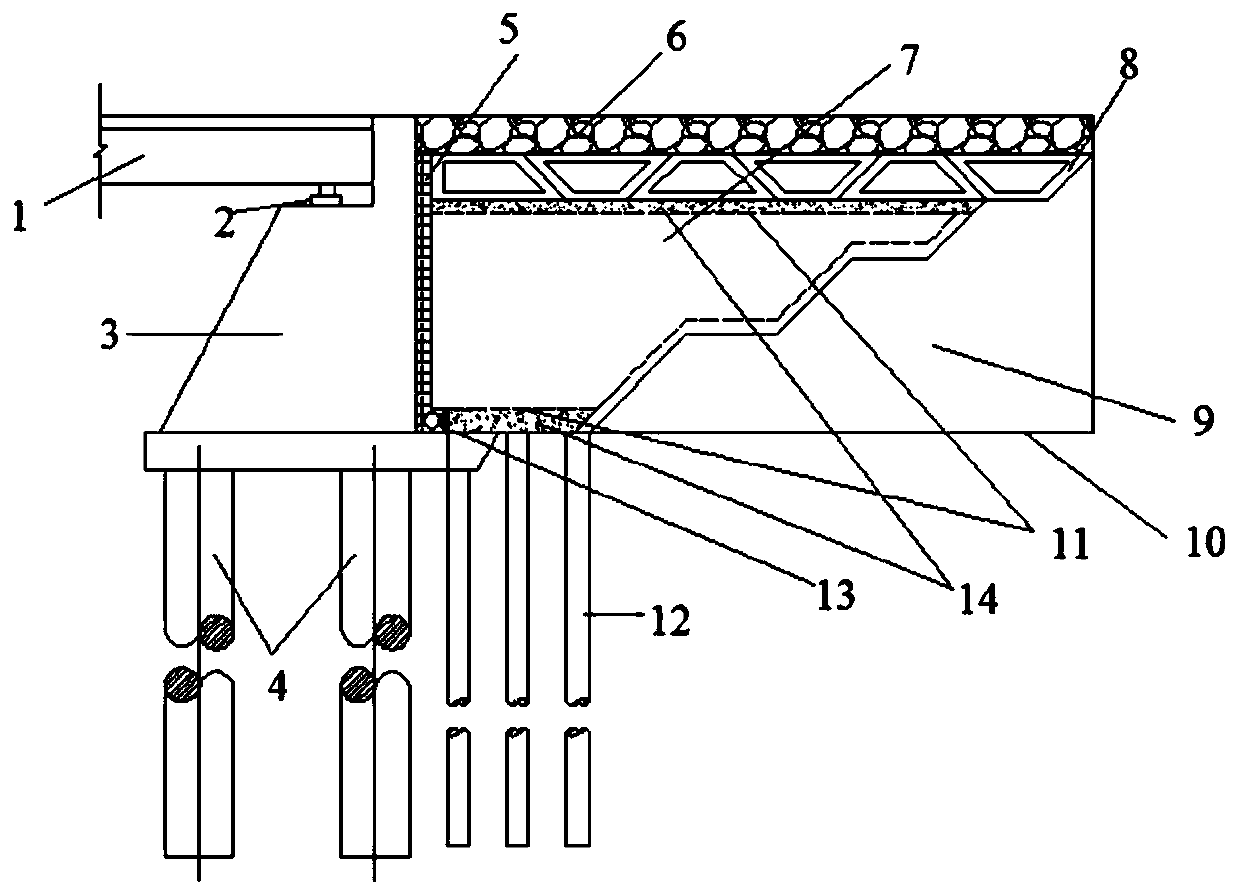

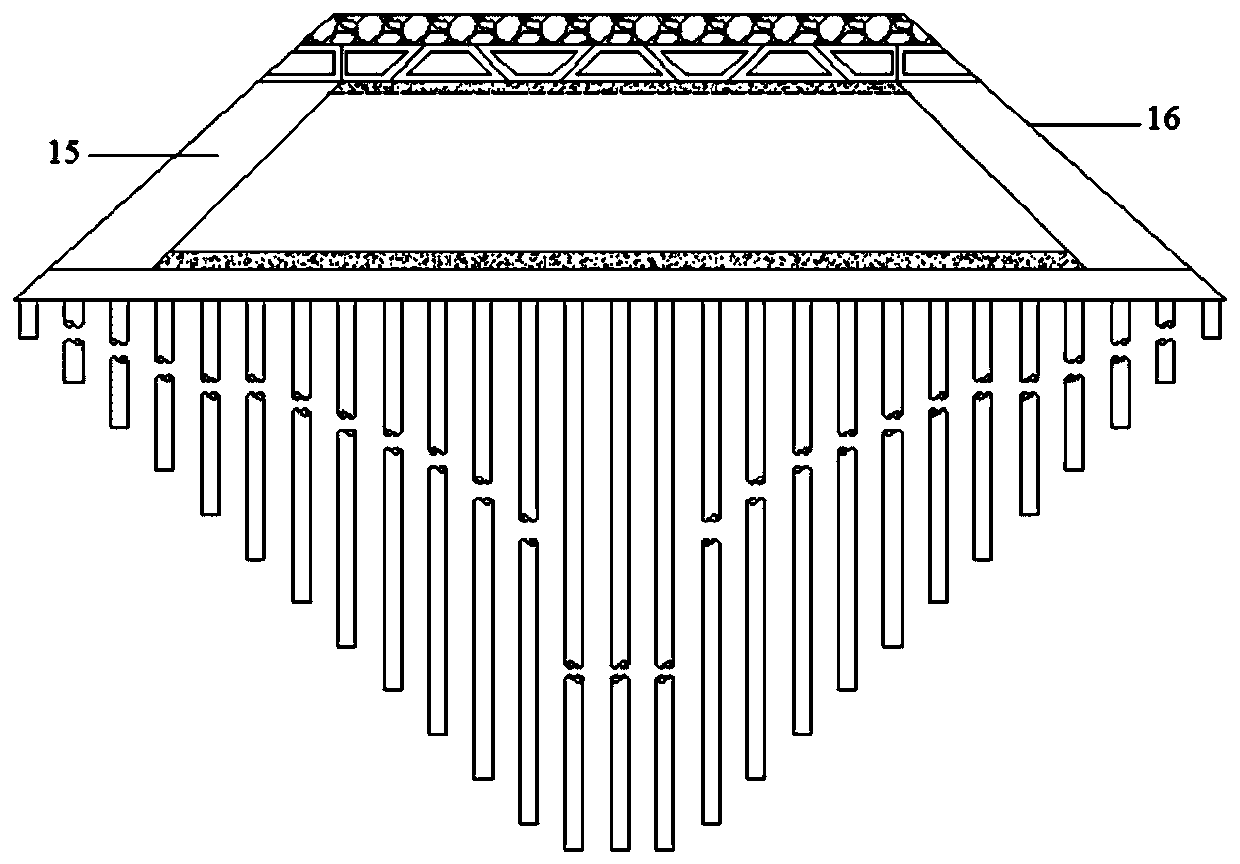

[0035] like figure 1 As shown, the present invention provides a subgrade for controlling the uneven settlement of the transition section of a high-speed railway road and bridge, including a subgrade body 9 and a transition subgrade arranged between the subgrade body 9 and the bridge abutment 3. The subgrade surface layer 6 is laid above the transition subgrade, and the bottom There are foundation reinforcement piles 12 arranged in the horizontal and vertical directions and extending into the underground soil layer.

[0036] The transition roadbed comprises a trapezoidal reinforced concrete body 8, a first foamed concrete body 7 and a second foamed concrete body 14 respectively laid on the upper top surface and the lower bottom surface of the first foamed concrete body 7, and the trapezoidal reinforced concrete body 8 is arranged on the first foamed concrete body 14. On top of the second foamed concrete body 14 on the top surface of the body 7 , the first foamed concrete body 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com