Discontinuous spiral baffle plate heat exchanger for cooling compressed air

A technology of spiral baffles and compressed air, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of difficult processing, low heat transfer efficiency in the central area, leakage, etc., to achieve The difficulty of assembly is small, the effect of ensuring heat transfer performance and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

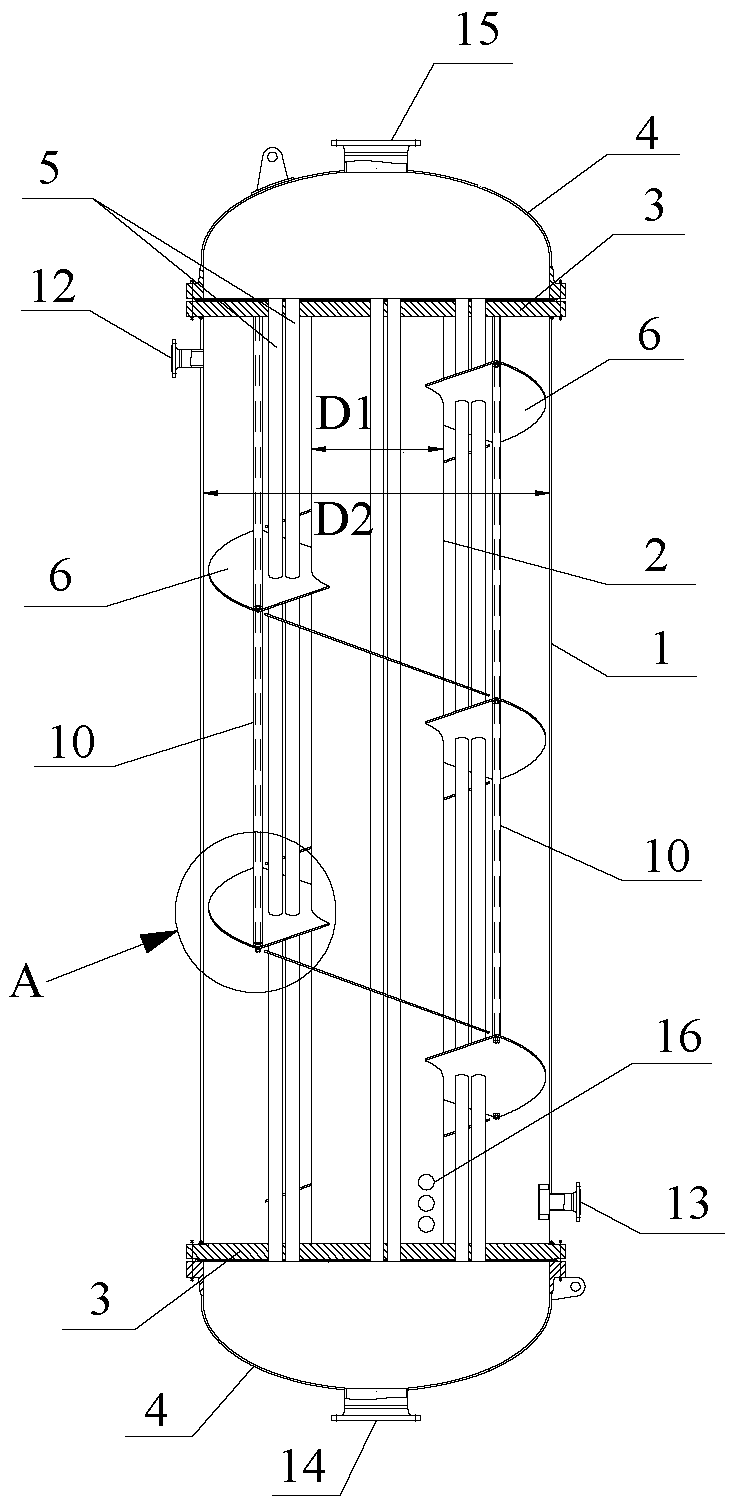

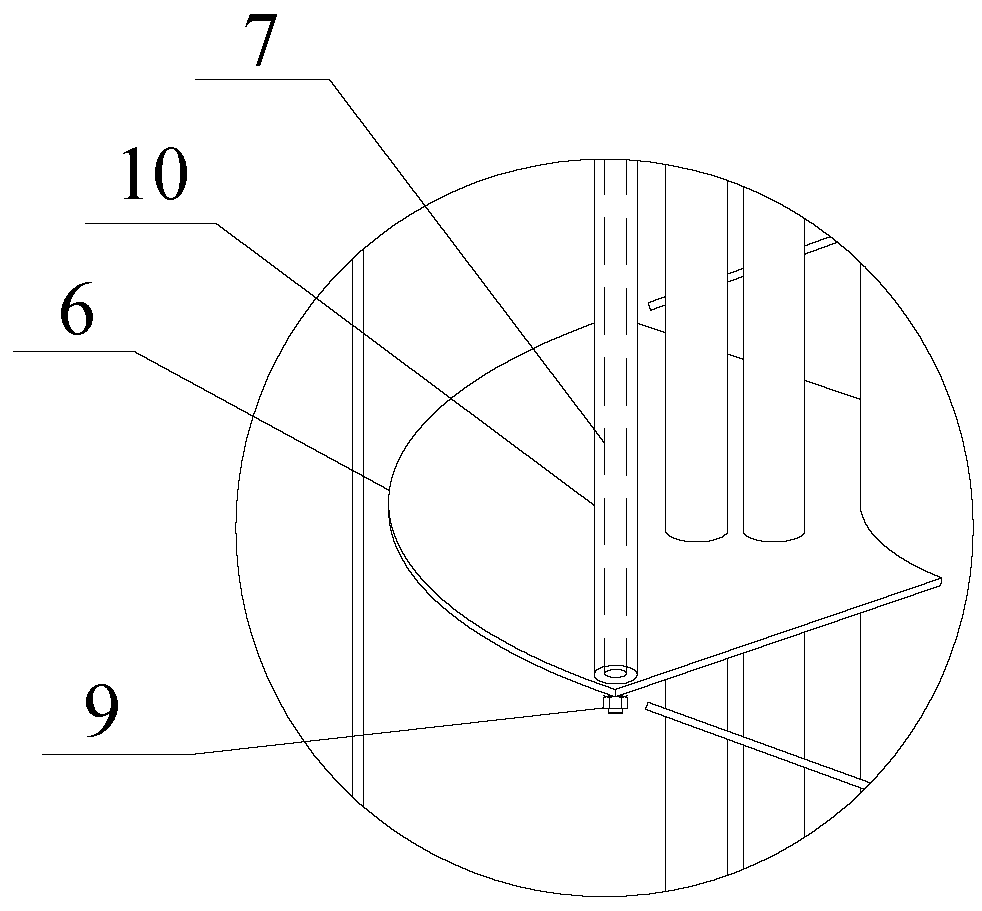

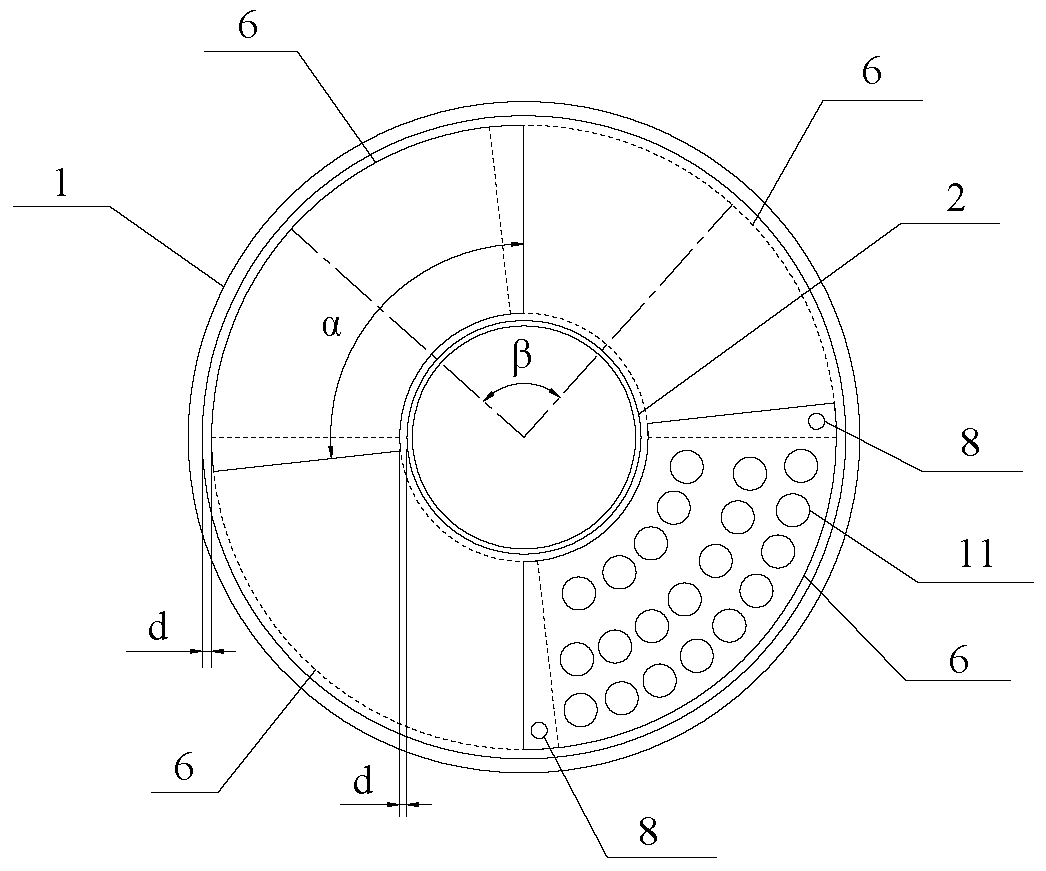

[0024] See Figure 1 to Figure 3 , a discontinuous spiral baffle heat exchanger for compressed air cooling according to the present invention, which includes an outer shell 1 and an inner shell 2 that are coaxially arranged and both are cylindrical, and the outer shell 1 and the inner shell 2 Tube sheets 3 are welded and fixed at both ends, tube boxes 4 are connected to the outside of tube sheets 3, spiral baffles and heat exchange tube bundles 5 are arranged in the outer shell 1 along the axial direction, and heat exchange tube bundles 5 pass through the spiral baffles and tubes. The plate 3 communicates with the pipe box 4; the diameter ratio of the outer shell 1 to the inner shell 2 is D1:D2=2:1~5:1; the spiral baffle is fixedly installed between the outer shell 1 and the inner shell 2, and the spiral The baffle is formed by at least four fan-shaped flat plates 6 arranged helically at a helix angle of 20°~30°, and two adjacent fan-shaped flat plates 6 overlap along the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com