Blasting dust decreasing device for building construction

A dust suppression device and construction technology, applied in the direction of blasting, liquid separation agent, dispersed particle separation, etc., can solve the problems of debris splashing, device damage, debris and device collision, etc., to improve stability, facilitate fixing, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

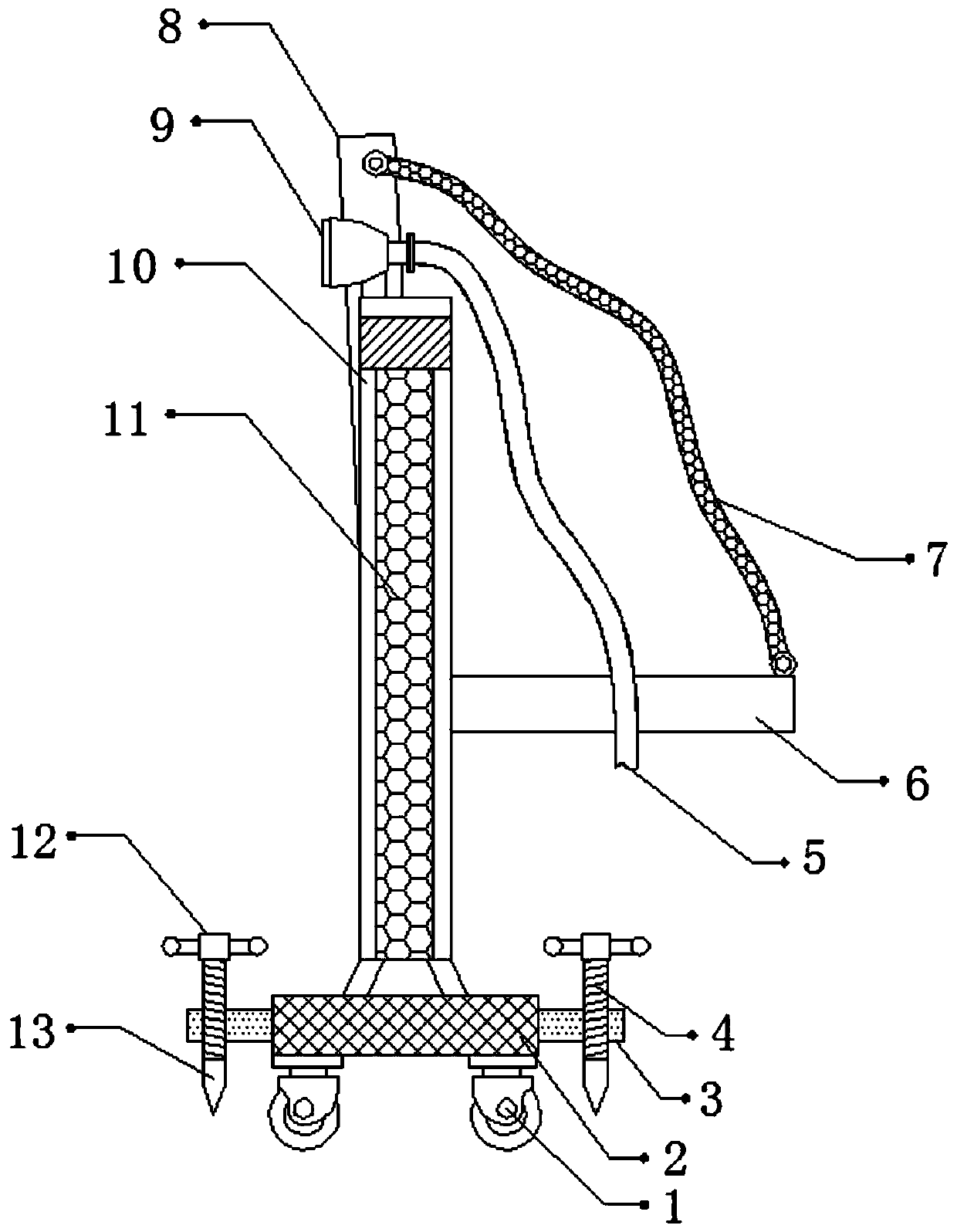

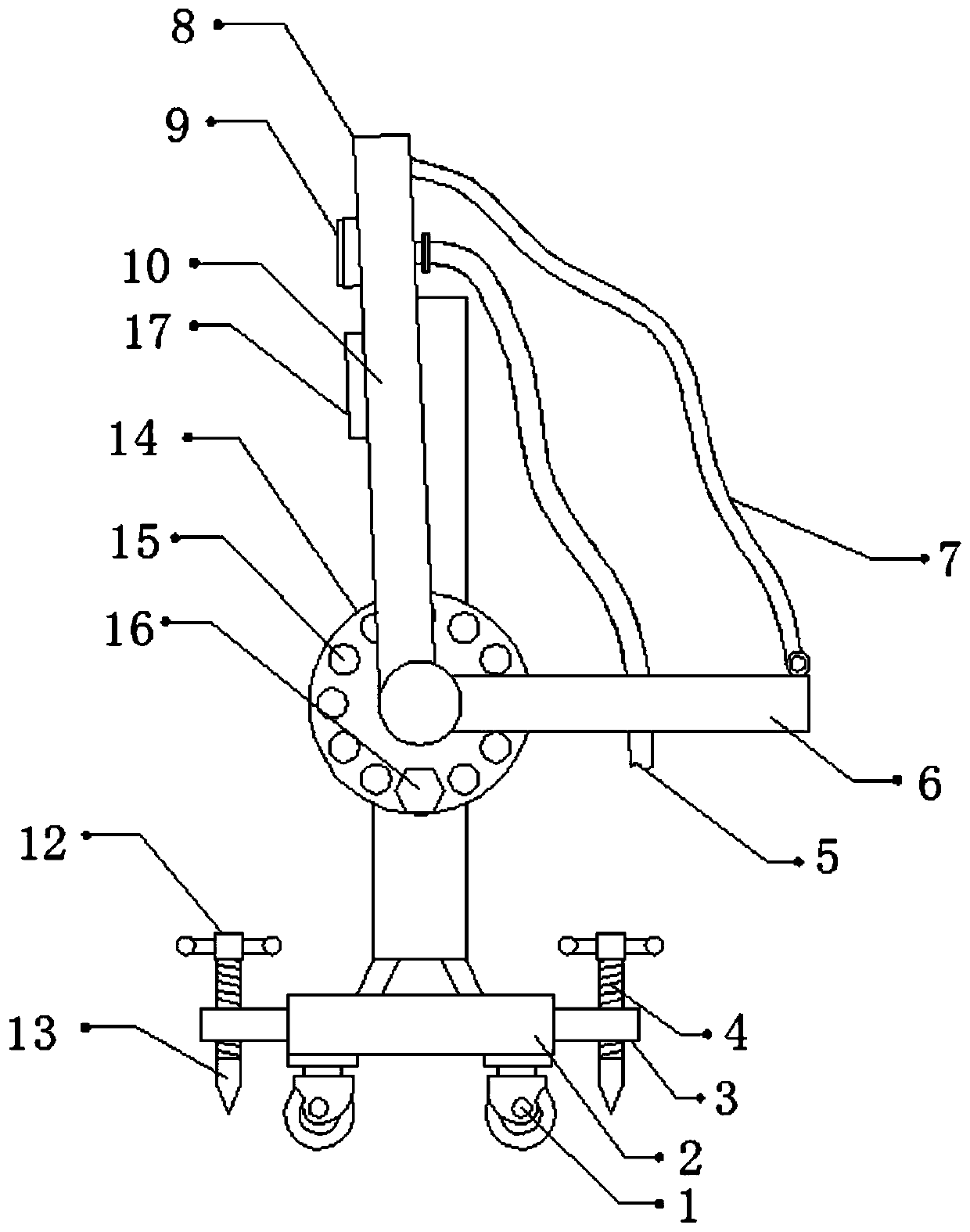

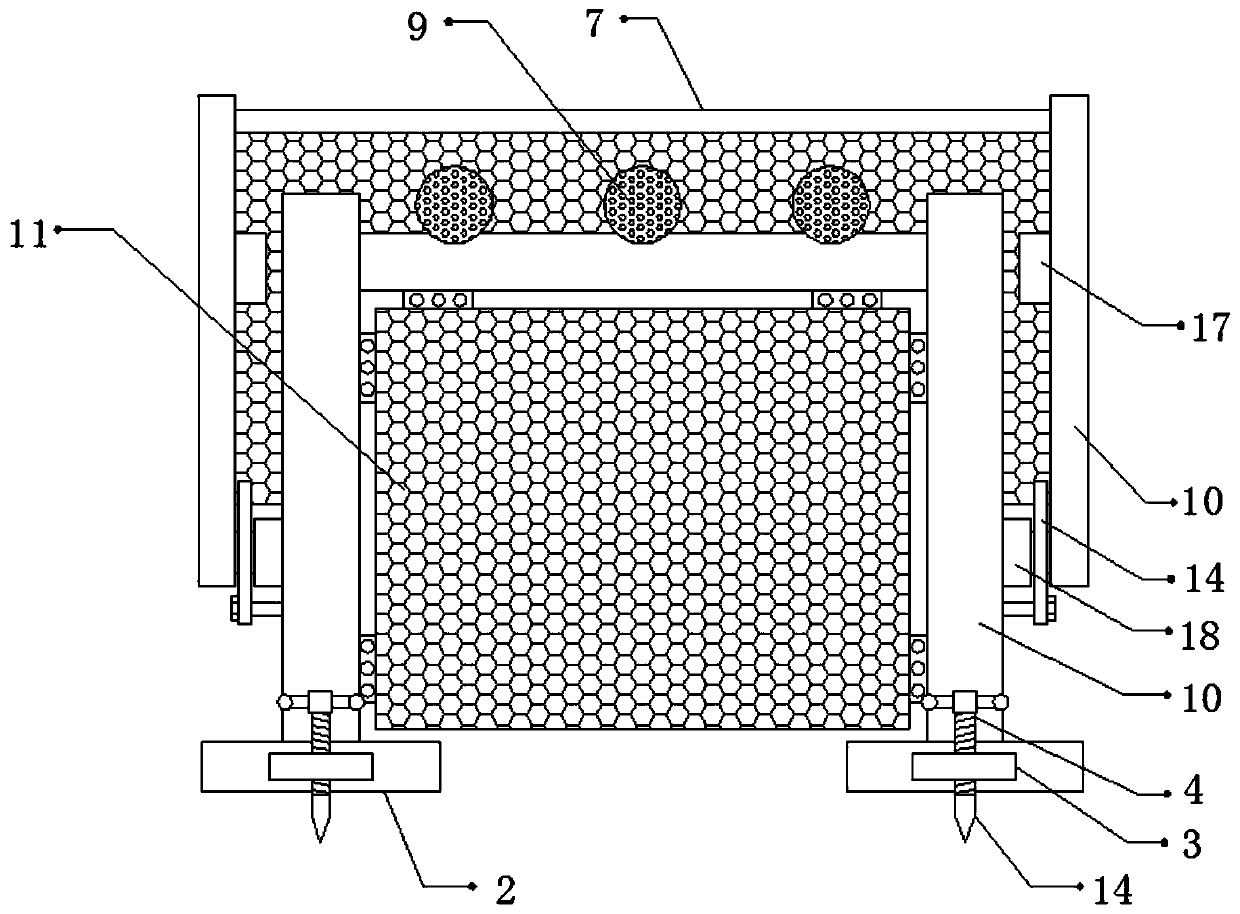

Embodiment 1

[0027] refer to Figure 1-4 , a blasting dust suppression device for building construction, comprising two fixed seats 2, the top outer walls of the two fixed seats 2 are connected with a fixed frame 10 by bolts, and the inner wall of the fixed frame 10 is connected with a steel wire mesh 11 through a hinge, the fixed frame The outer walls on both sides of 10 are connected with fixed plates 6 by bolts, and the outer walls of one side of the two fixed plates 6 are connected with damping bearings 18 by bolts, and the inner walls of the two damping bearings 18 are all rotatably connected with rotating shafts, and the two One side outer wall of the rotating shaft is connected with a rotating rod 8 by bolts, and the opposite side outer walls of the two rotating rods 8 are connected with a protective net 7 by bolts, and the top inner wall of the fixed frame 10 is connected with a support seat by bolts, and The top outer wall of the support seat is connected with an atomizing nozzle ...

Embodiment 2

[0035] refer to Figure 5 , a blasting dust suppression device for building construction. Compared with Embodiment 1, the outer walls of the bottom of the two fixing seats 2 are provided with U-shaped grooves 22, and the top inner walls of the two U-shaped grooves 22 are connected by bolts. There are hydraulic rods 19, the bottom outer walls of the two hydraulic rods 19 are connected with support plates 21 by bolts, and the bottom outer walls of the two support plates 21 are provided with a plurality of fixed teeth 20 distributed equidistantly.

[0036] Working principle: when in use, the device is moved to a suitable position through the moving wheel 1. After the movement is completed, the handle 12 is turned to make the threaded rod 4 drive the insertion rod 13 to rotate, so that the insertion rod 13 is inserted into the soil for convenience. Fix the device to prevent the device from falling due to the impact force generated during blasting and thus affect the dust fall. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com