Ultrasonic method for real-time detection of uniform hoop binding force of circular concrete filled steel tube columns

A concrete column, real-time detection technology, applied in the direction of measuring force, column, pillar, etc., can solve the problems of reduced sensitivity, unintuitive reading, difficult to promote, etc., to achieve the effect of high sensitivity, real-time monitoring of safety and health, and intuitive measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

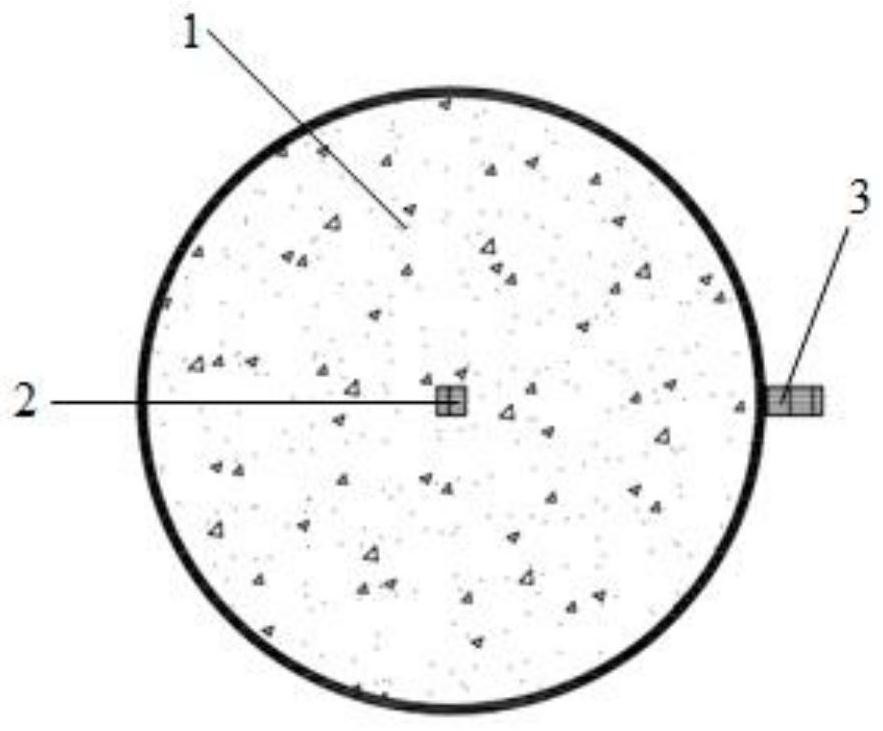

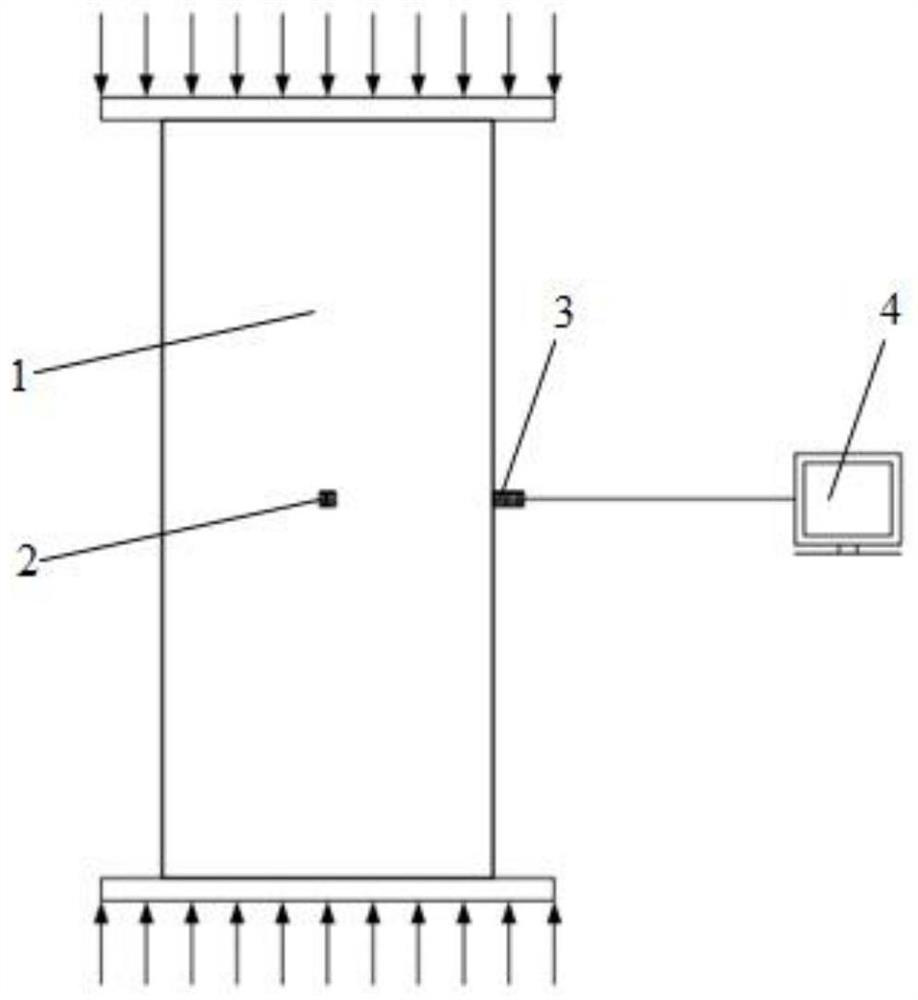

[0022] See figure 2 , Is a schematic structural diagram of a detection device corresponding to a method for ultrasonic real-time detection of the uniform hoop restraint force of a circular steel tube concrete column provided by an embodiment of the present invention. The detection device includes a concrete-filled steel tube column to be tested 1, an ultrasonic transmitting sensor 2, a signal amplifier device, an ultrasonic receiving device 3 and a computer 4. Wherein, the concrete-filled circular steel tube column 1 to be tested is preferably self-compacting concrete pouring, the ultrasonic transmitting sensor 2 is embedded in the center of the cross section of the column before the core concrete is poured, and the ultrasonic receiving device 3 is closely attached to the circular steel tube to be tested The outer surface of the cross-section steel pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com