Ultrasonic-based method for non-destructive measurement of active and passive confinement forces in frp-confined concrete columns

A technology for confining concrete and concrete columns, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, and applying stable tension/compression to test material strength, etc. It can solve the unsafe and axial compressive strength of FRP-confined concrete in calculation results The model cannot directly use FRP to constrain concrete and other issues, achieving real-time monitoring of safety and health, intuitive measurement results, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

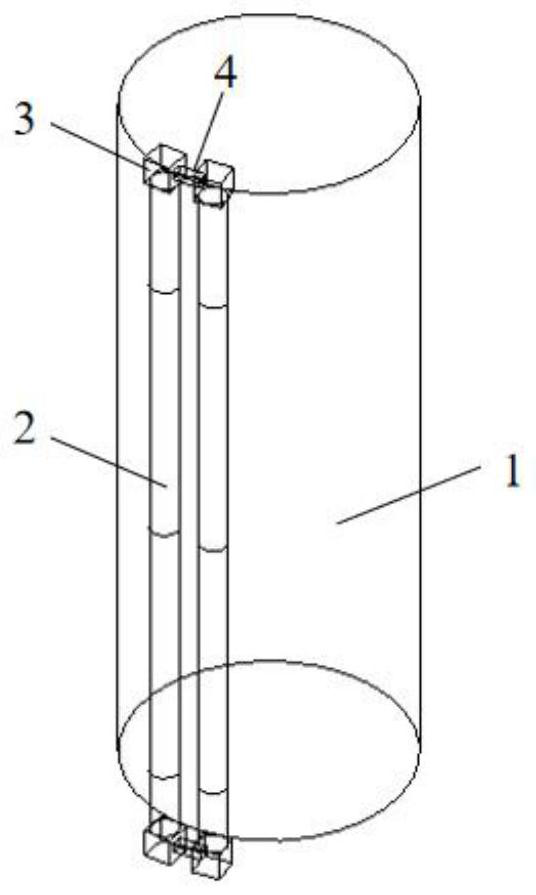

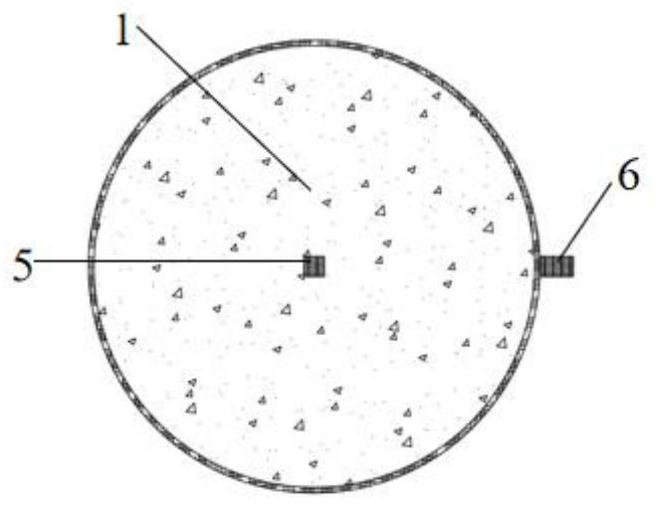

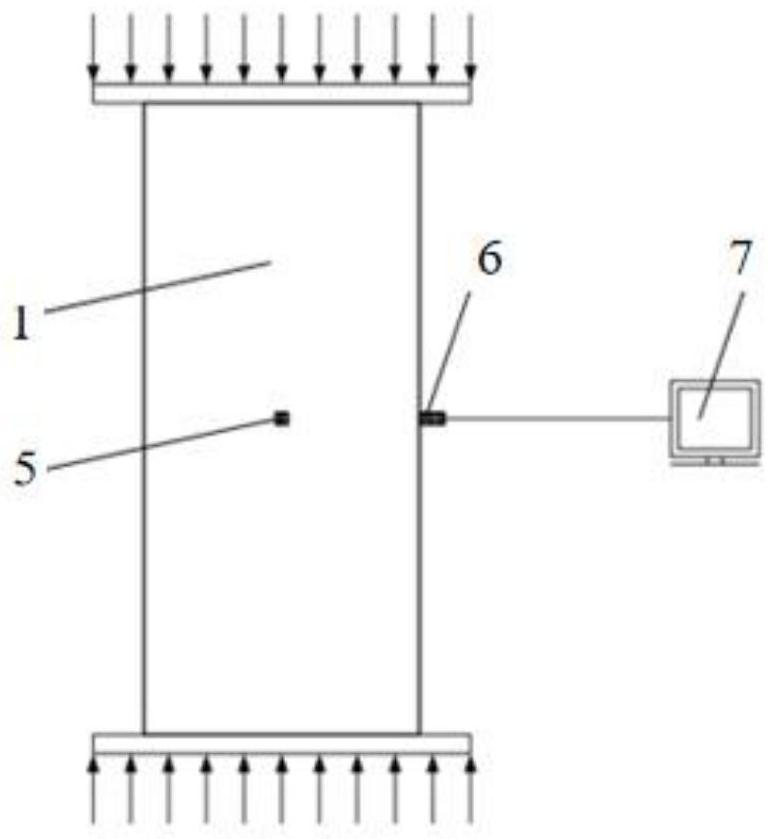

[0023] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme of the present invention and the accompanying drawings.

[0024] As shown in the figure, the embodiment of the present invention provides a detection device corresponding to the ultrasonic-based non-destructive measurement of the active and passive restraint force methods of FRP-confined concrete columns. The detection device includes an FRP confined concrete column 1 to be tested, an ultrasonic transmitting sensor 5 , a signal amplifying device, an ultrasonic receiving device 6 and a computer 7 . Wherein, the ultrasonic transmitting sensor 5 is embedded in the central position of the required measurement section in the column before the core concrete is poured, and the ultrasonic receiving device 6 is closely attached to the FRP outer surface of the middle section of the FRP confined concrete column 1 to be measured. Preferably, The ultrasonic tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com