Test method for measuring uniform and non-uniform constraining force of concrete filled steel tubular column by adopting piezoelectric film

A kind of technology of concrete filled steel tubular column and piezoelectric film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

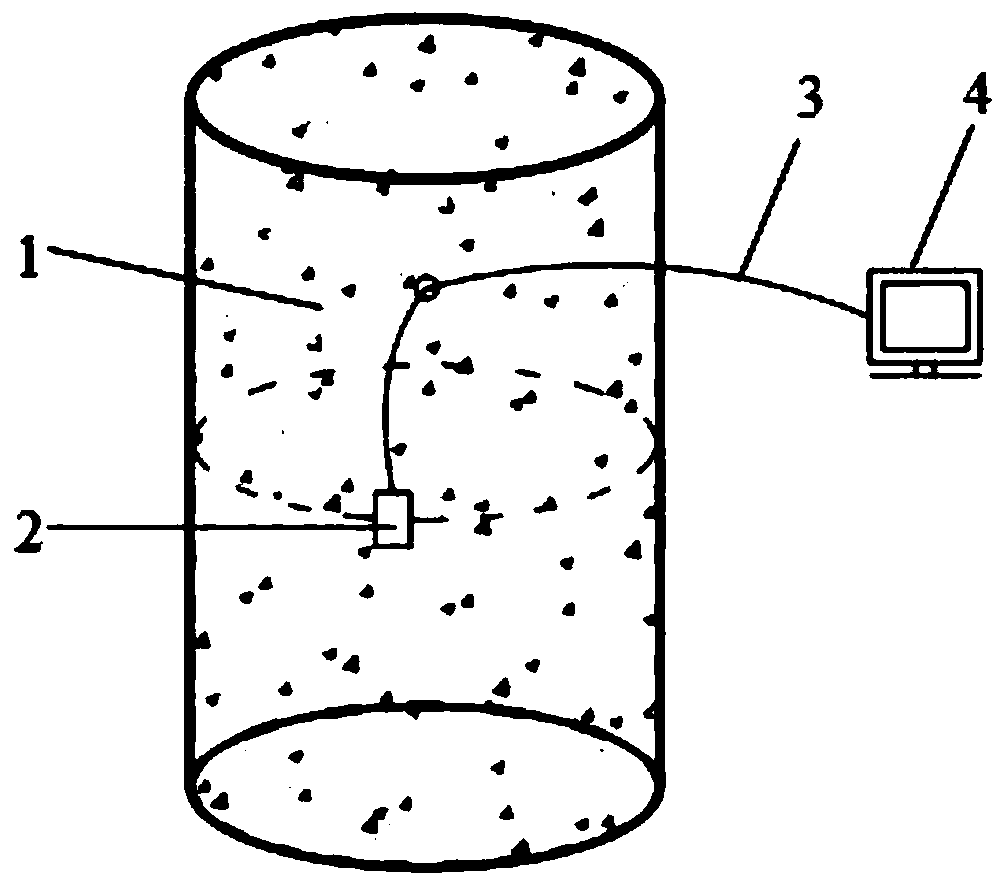

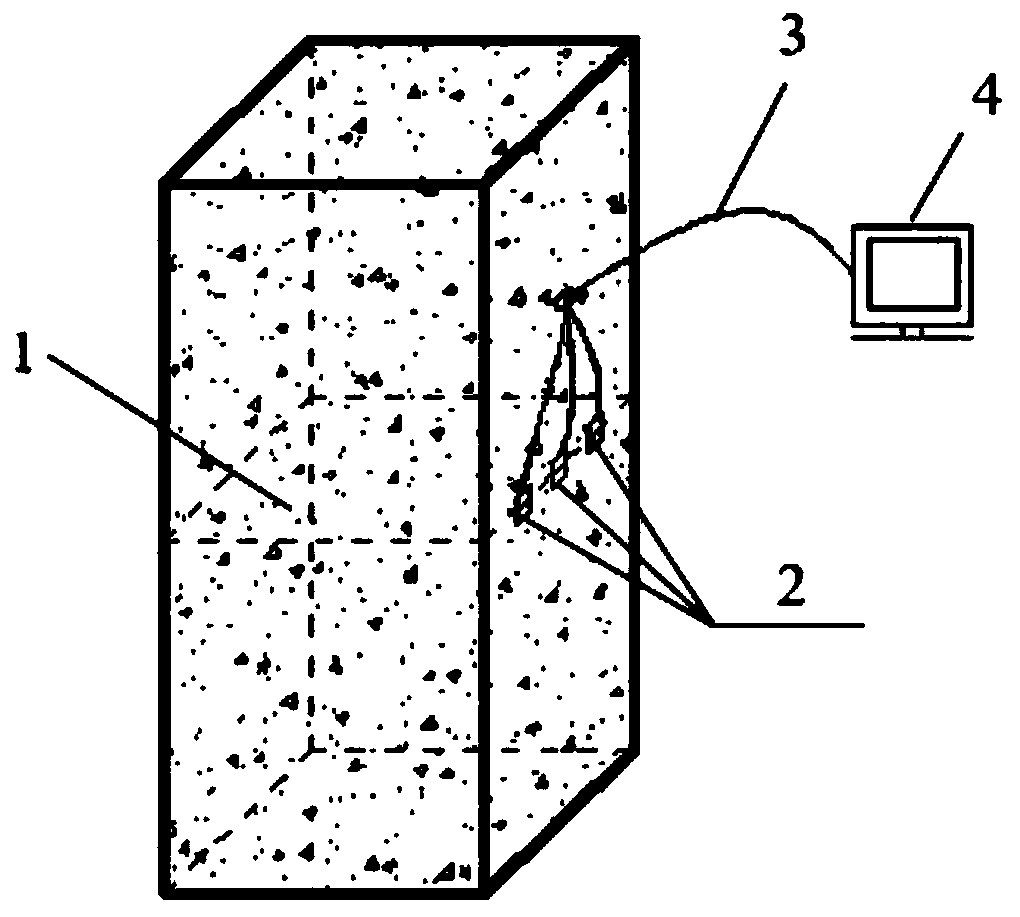

[0017] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme of the present invention and the accompanying drawings. Before the core concrete is poured, the piezoelectric film 2 with a thickness of only 28 μm is pasted on the inner side of the steel pipe. When the steel tube concrete column 1 is under load, the change of the electrical signal between the upper and lower electrodes of the piezoelectric film 2 can directly obtain uniformity and non-uniformity. restraint pressure.

[0018] Specifically, the method includes the following steps:

[0019] (1) For a concrete-filled steel tube column 1 with a diameter of 219 mm and a length of 657 mm, the self-compacting concrete with a compressive strength of C40 is filled inside, before the core concrete is poured, the thickness is only 28 μm, and the size is 0.6 cm × 0.9 cm , the effective area is 0.35cm 2 , with a dielectric constant of 110×10 -12 The piezoe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com