Test Method for Measuring Uniform and Inhomogeneous Constraint Forces of Concrete-filled Steel Tube Columns Using Piezoelectric Films

A technology of concrete filled steel tubular column and piezoelectric film, which is applied to the measurement, measuring device, column, etc. of the property force of piezoelectric devices, which can solve the problem of uneven confinement of core concrete, and the inability to install the measuring device. No report has yet been reported. and other problems, to achieve the effect of real-time monitoring of safety and health, easy measurement operation, and intuitive measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

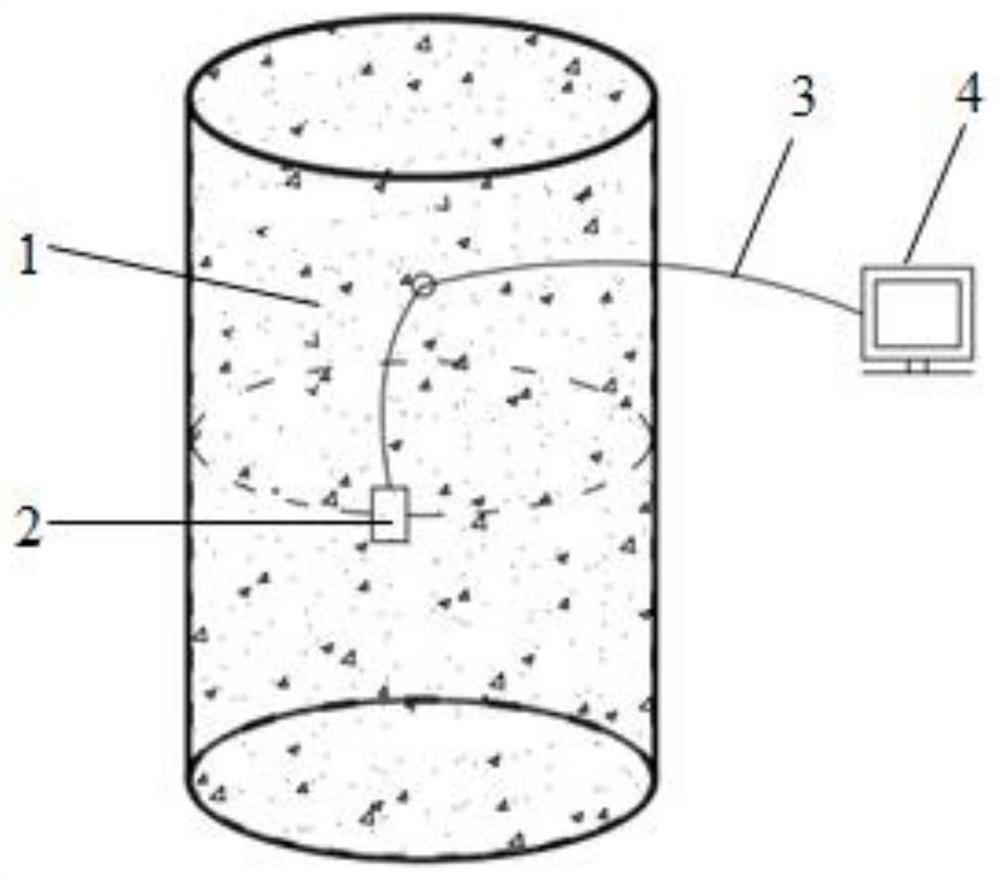

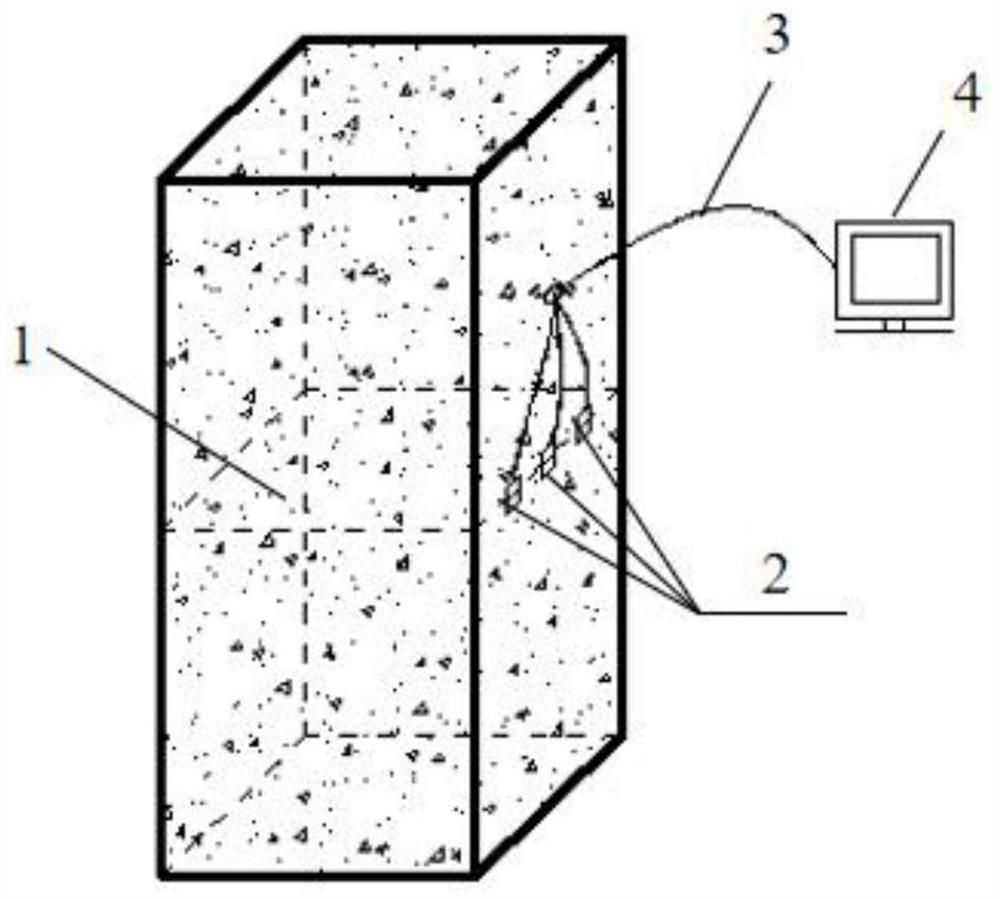

[0017] The specific embodiments of the present invention will be described below in conjunction with the technical solutions of the present invention and the drawings. The piezoelectric film 2 having only 28 μm is only in the inside of the steel pipe before the core concrete is pouring, and when the steel pipe concrete column 1 is loaded, the electrical signals between the electrodes of the upper and lower electrodes can be directly obtained and uniformly. Constraint pressure.

[0018] Specifically, the method includes the steps of:

[0019] (1) For a certain diameter of 219 mm, a steel pipe concrete 1 with a length of 657 mm, an internal filling compressive strength of C40, before the core concrete pouring, the thickness is only 28 μm, the size is 0.6 cm × 0.9cm. , Effective area of 0.35cm 2 , Dielectric constant is 110 × 10 -12 The piezoelectric film 2 is attached to the inside of the steel pipe, and the opening lead lead 3 outputs the piezoelectric signal at the outgoing posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com