Test method for measuring active and passive hooping forces of FRP confined concrete column by adopting piezoelectric film

A technology that constrains concrete and piezoelectric films, applied in the field of piezoelectric materials, can solve problems such as inability to install, achieve intuitive measurement results, real-time monitoring of safety and health, and easy measurement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme of the present invention and the accompanying drawings. Specific steps are as follows:

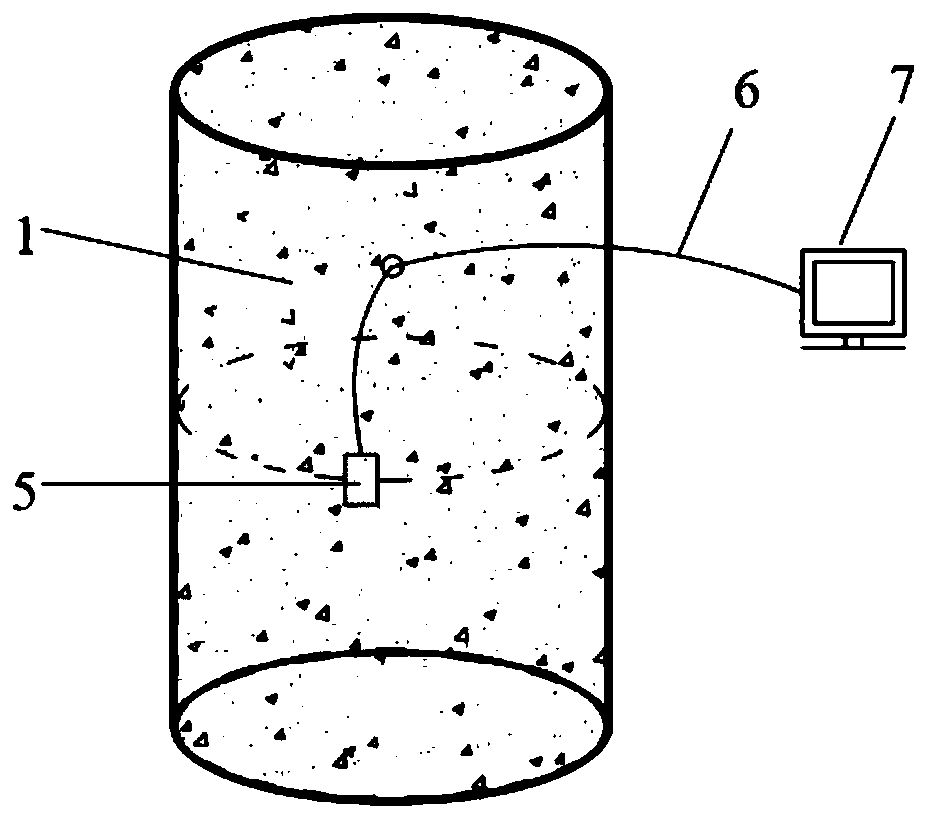

[0021] (1) The structural column to be tested is a concrete column with a diameter of 150mm and a length of 500mm, and the concrete compressive strength is C30; before the FRP-confined concrete column 1, the thickness is only 28μm, the size is 0.6cm×3cm, and the effective area is 1.2cm 2 , with a dielectric constant of 110×10 -12 The piezoelectric film 5 is attached to the side wall of the core concrete, and the wire 6 is drawn out from the gap between the FRP fiber filaments at a distance of 2d to 10d from the veneer to output a piezoelectric signal;

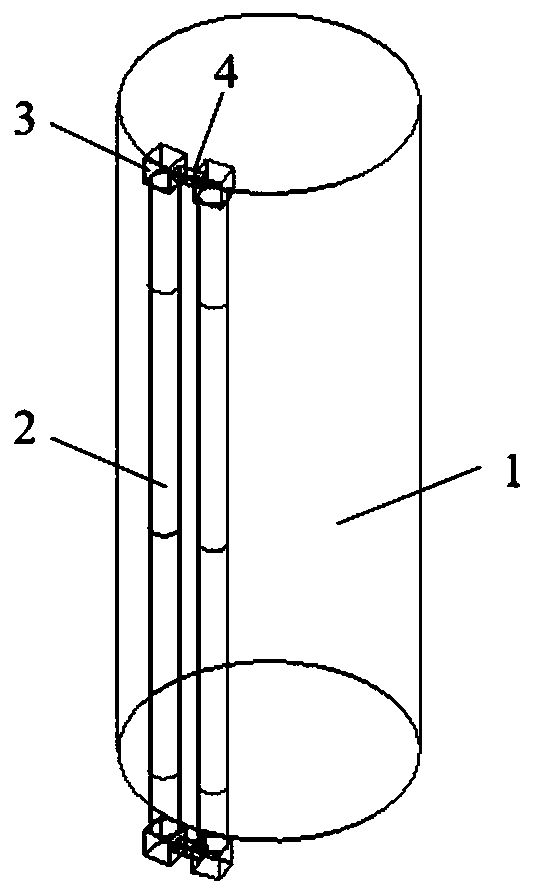

[0022] (2) Stretch the FRP through the self-locking prestressing device (including the anchor head 2 of the self-locking prestressing tensioning device, the nut 3 of the self-locking prestressing tensioning d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com