Device and method for in-situ measurement of rock abrasion degree and needle penetration degree

An in-situ measurement and penetration technology, applied in the direction of measuring devices, testing wear resistance, strength characteristics, etc., can solve problems such as experimental errors, inconvenience, unfavorable wear mechanism analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of method of in-situ measurement rock abrasiveness, it comprises the following steps:

[0043] Step 1): opening channels on the original rock;

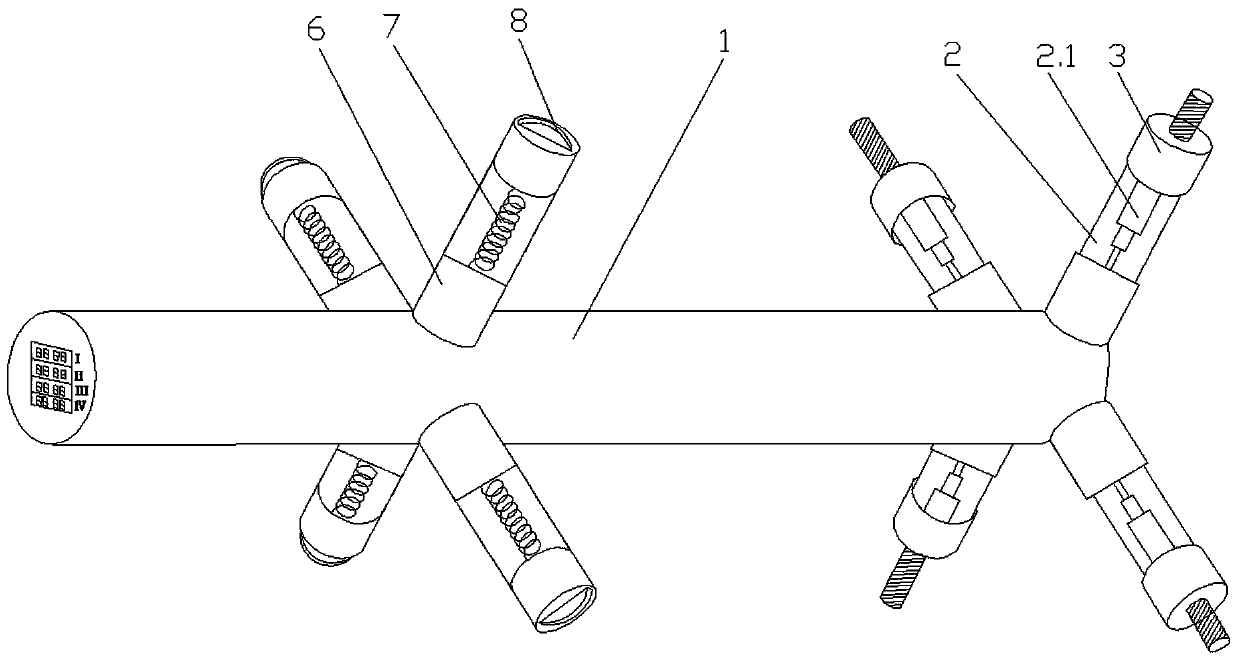

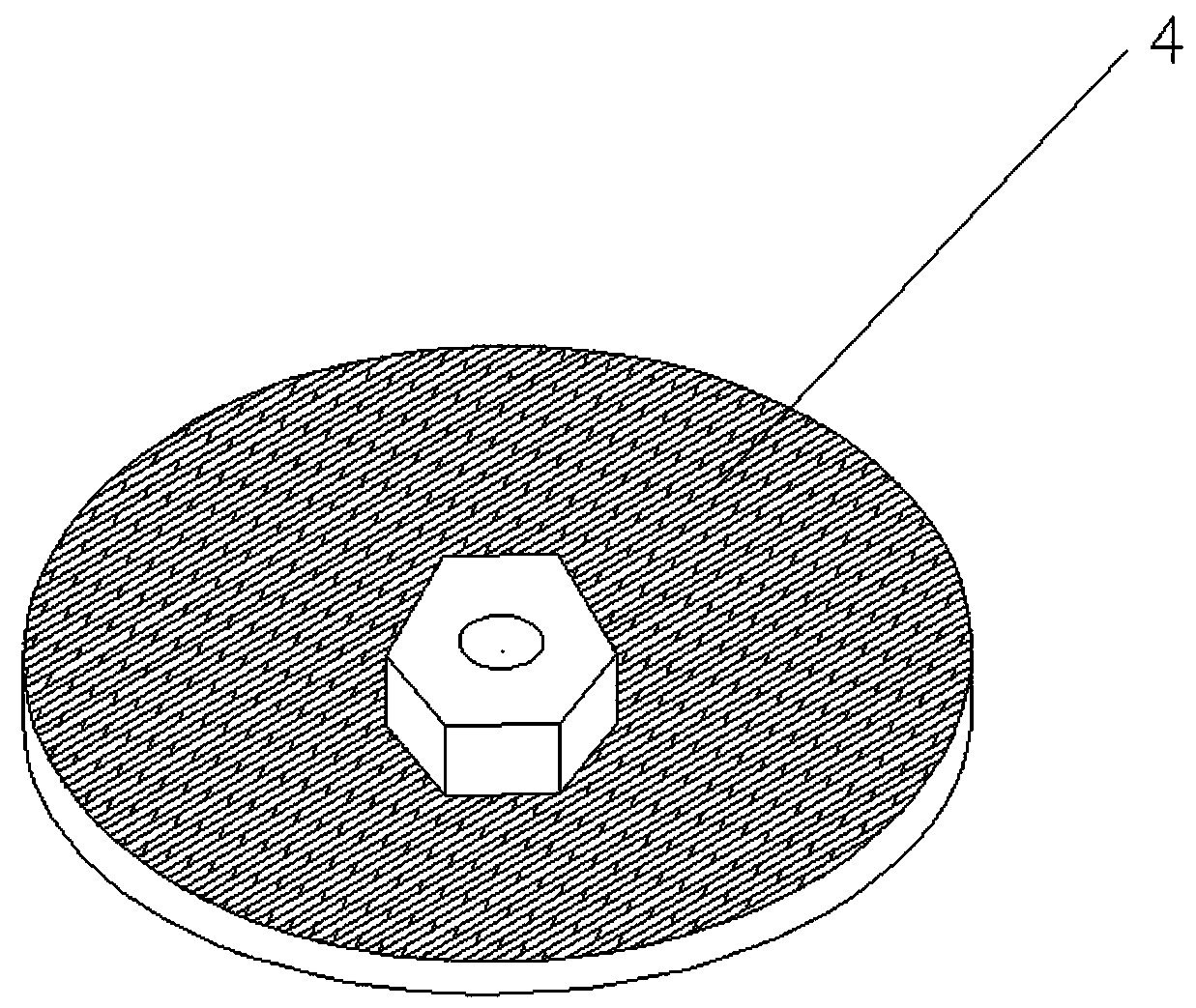

[0044] Step 2): After installing the grinding disc 4 on the output shaft of the motor 3, put the whole device into the hole;

[0045] Step 3): Make the moving rod 1 extend into the tunnel to a certain depth, and then turn on the telescopic device 2 and the motor 3, so that the grinding disc 4 presses the inner wall of the tunnel with a constant pressure;

[0046] Step 4): The grinding disc 4 continuously rotates at a constant speed while pressing the inner wall of the tunnel, and the abrasive depth of the rock under a fixed pressure per unit time is the abrasiveness of the rock.

[0047] Preferably, in the step 1), the holes opened on the original rock have a cubic hole structure; in the step 3), the number of telescopic devices 2 is 4, and the surface of the grinding disc 4 installed on the motor 3 at the e...

Embodiment 2

[0048] Embodiment 2: In order to measure the penetration of rock at the same depth, this embodiment discloses a method for measuring the penetration of rock in situ, which includes the following steps:

[0049] Step 1): opening a cylindrical channel on the original rock;

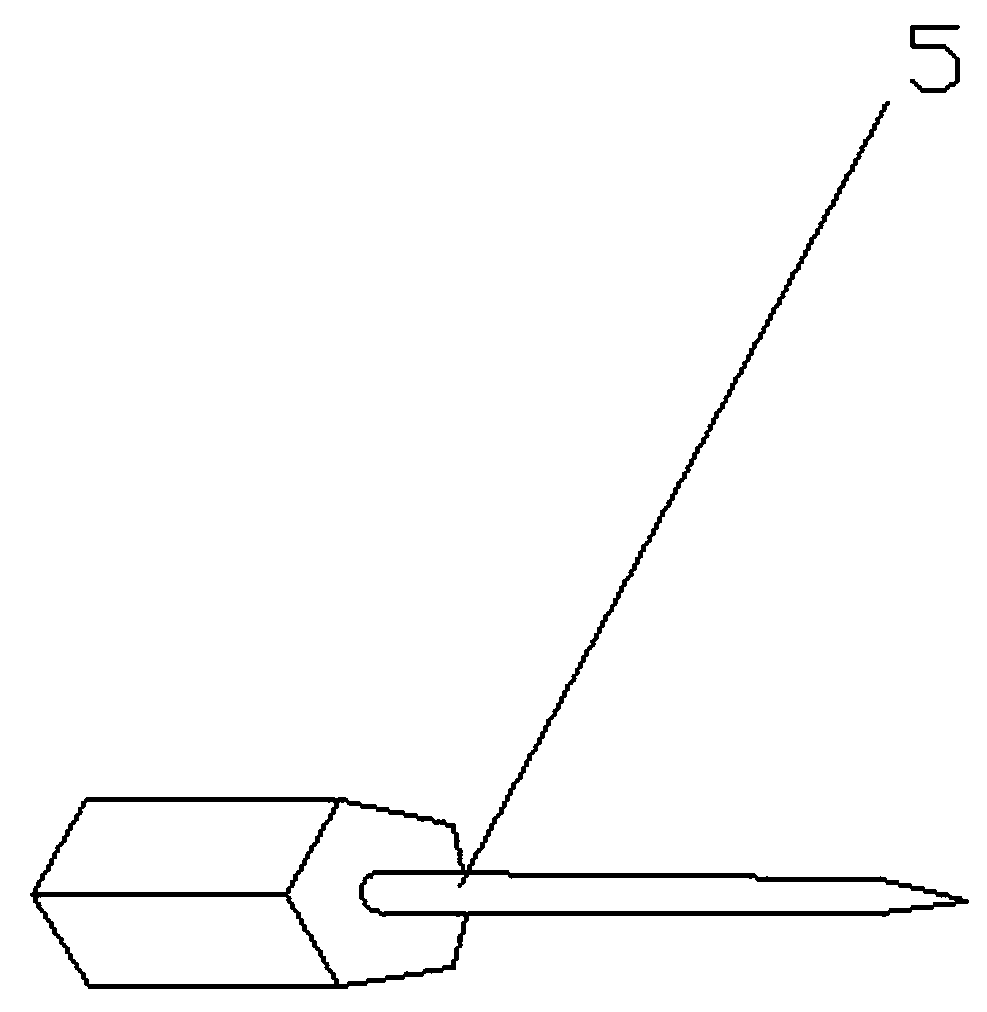

[0050] Step 2): After installing the needle valve 5 on the output shaft of the motor 3, put the whole device into the tunnel;

[0051] Step 3): Make the moving rod 1 extend into the tunnel to a certain depth, and then open the telescopic device 2, so that the needle valve 5 presses the inner wall of the tunnel with a constant pressure, and keeps the moving rod 1 rotating at a constant speed;

[0052] Step 4): The needle valve 5 continuously passes along the circumference of the inner wall of the tunnel while pressing against the inner wall of the tunnel, and the penetration depth of the needle valve 5 under a fixed pressure per unit time is the penetration of the rock at the same depth.

Embodiment 3

[0053] Embodiment 3: In order to measure the penetration of rocks at different depths, this embodiment discloses another method for measuring the penetration of rocks in situ, which includes the following steps:

[0054] Step 1): opening channels on the original rock;

[0055] Step 2): After installing the needle valve 5 on the output shaft of the motor 3, put the whole device into the tunnel;

[0056] Step 3): Open the telescopic device 2 to make the needle valve 5 press the inner wall of the tunnel with a constant pressure, and make the moving rod 1 move to the bottom of the tunnel at a constant speed;

[0057] Step 4): The needle valve 5 continuously draws a straight line along the inner wall of the channel to the depth of the channel while pressing against the inner wall of the channel, and the depth of needle penetration of the needle valve 5 under the constant pressure applied to the inner wall of the channel at different depths per unit time is the depth of the differen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap