A multi-component composite material, electrochemical sensor and its application in detecting mercury ions in water

A composite material and sensor technology, which is applied in the field of mercury ion detection, can solve the problems of high instrument requirements, expensive equipment cost, and complicated detection process, and achieve high sensitivity, high selectivity and affinity, and high detection specificity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A GS-Au / AuNPs / g-C 3 N 4 A method for preparing a composite material, the method comprising the following steps:

[0046] (1) Weigh 2g of urea, heat it to 600°C at a heating rate of 4°C / min in an argon atmosphere, and keep it for 4h. After calcination, let it cool to room temperature naturally, take it out, and prepare carboxyl-modified g-C 3 N 4 powder.

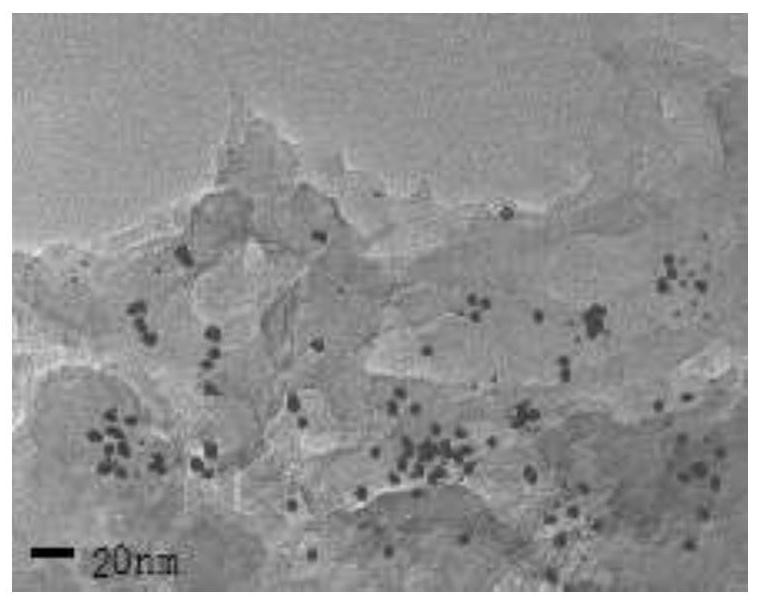

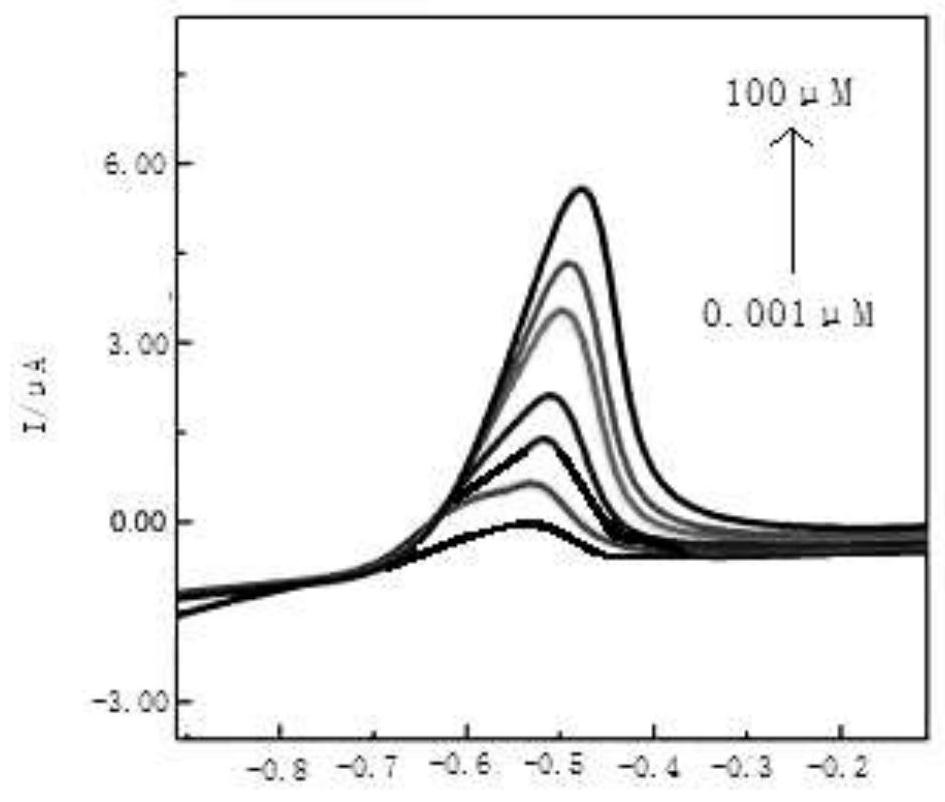

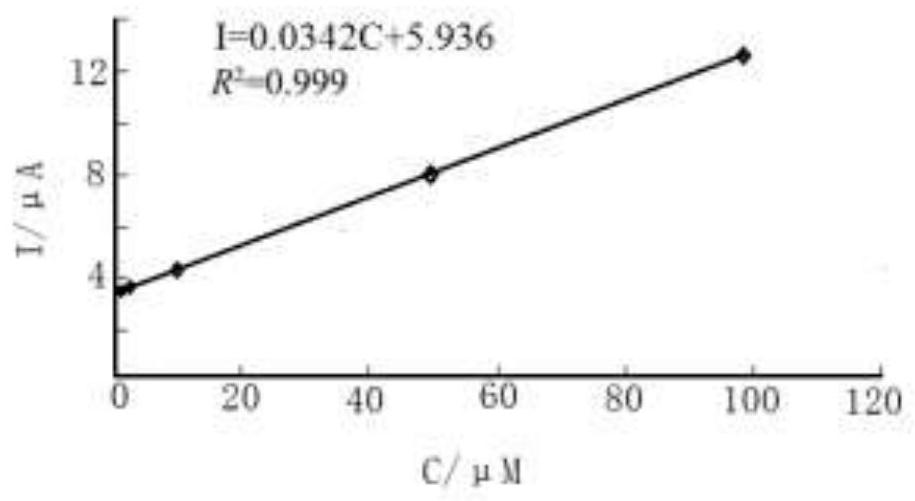

[0047] (2) 12mg g-C 3 N 4 Disperse the powder into 4mL of methanol, add 8mg of glutathione, 1mL, 8mg / mL of chloroauric acid aqueous solution, and sonicate for 1.5h; ℃, the time is 18h; after the reflux, centrifuge at 5000rpm for 5min, collect the product, wash with deionized water, and vacuum overnight at 80℃ after washing; the GS-Au / AuNPs / g-C 3 N 4 Composite material, as shown in transmission electron microscope figure 1 As shown, it can be seen that the composite material presents a thin layer, g-C 3 N 4 The matrix is full of GS-Au complexes (shown as a slightly darker color in the figure), and there are ...

Embodiment 2

[0049] A GS-Au / AuNPs / g-C 3 N 4 A method for preparing a composite material, the method comprising the following steps:

[0050] (1) Weigh 2g of urea, heat it to 650°C at a rate of 3°C / min in an argon atmosphere, and keep it for 5h. After calcination, let it cool to room temperature naturally, take it out, and prepare carboxyl-modified g-C 3 N 4 powder.

[0051] (2) 15mg g-C 3 N 4 Disperse the powder into 5mL of methanol, add 10mg of glutathione, 1mL, 10mg / mL of chloroauric acid aqueous solution, and sonicate for 1h; after the sonication, transfer the above reaction system to a three-neck flask reflux device for heating and reflux at a temperature of 70°C , the time is 15h; after the reflux, centrifuge at 5000rpm for 5min, collect the product, wash with deionized water, and vacuum overnight at 80°C after washing; the GS-Au / AuNPs / g-C 3 N 4 composite material.

Embodiment 3

[0053] A method for preparing an electrochemical sensor for detecting mercury ions in water, the method comprising the following steps:

[0054] (1) The composite material in Example 1 is dispersed with deionized water to make a dispersion with a concentration of 10 mg / mL;

[0055] (2) The glassy carbon electrode was polished with 6# metallographic sandpaper, 3 micron, 0.5 micron, and 0.05 micron alumina powder for 3 minutes respectively, then ultrasonically cleaned with absolute ethanol and deionized water, and dried with nitrogen;

[0056] (3) Immerse the pretreated glassy carbon electrode in the dispersion solution of step (1) for 10 minutes, and after the immersion, dry it with nitrogen gas to obtain an electrochemical sensor for detecting mercury ions in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com