Surface-modified nano-zirconia ceramic powder and preparation method thereof

A nano-zirconia and surface modification technology, applied in the field of powder, can solve the problems of low fine grinding efficiency, high cost, and reduce the fluidity of powder particles, so as to ensure the classification efficiency, prolong the service life, and ensure the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

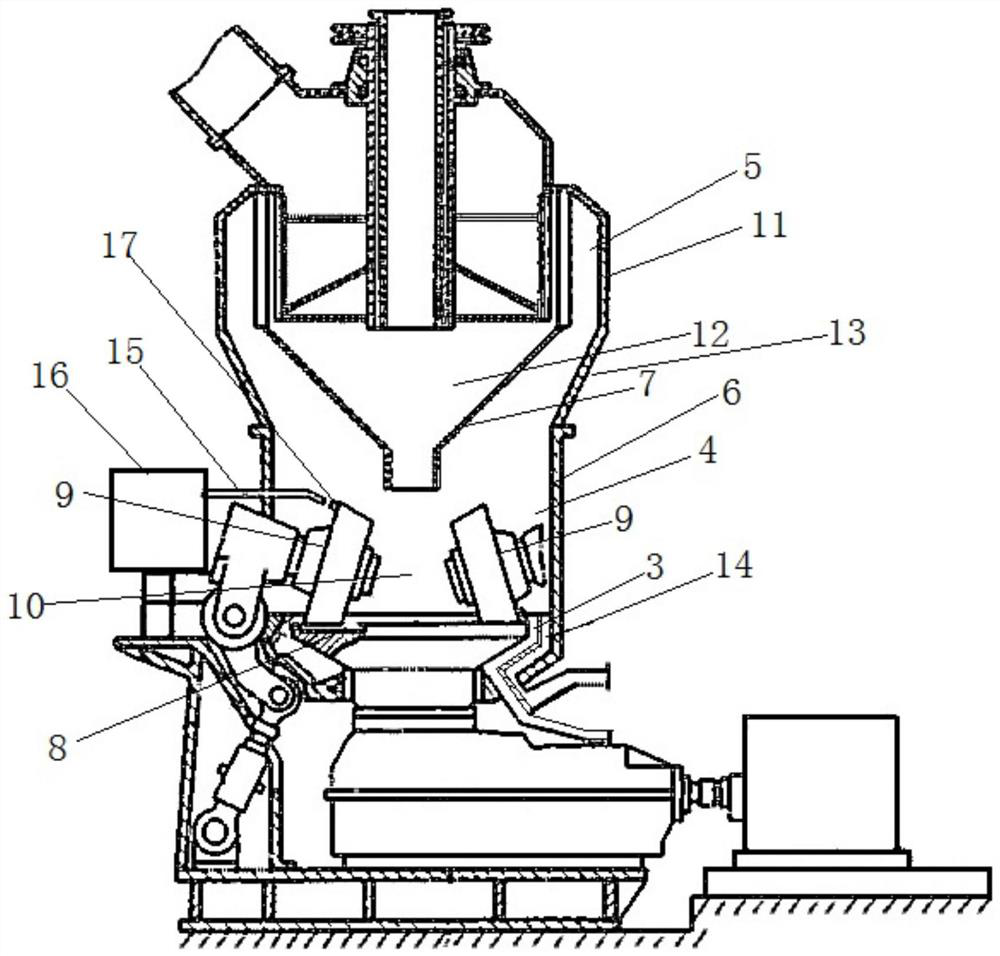

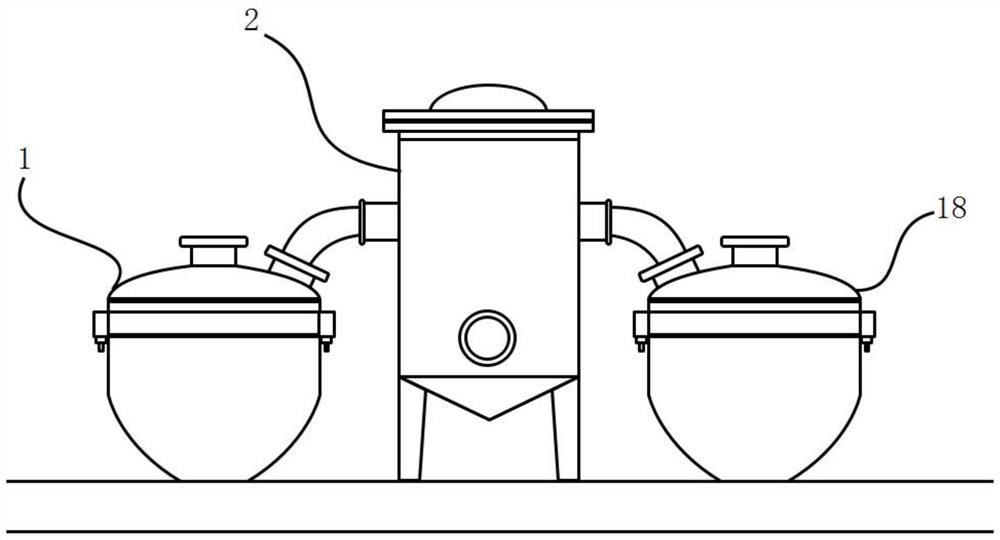

Image

Examples

Embodiment approach

[0056] According to a preferred embodiment, in the preparation method, the parts by weight of the nano-zirconia powder are 95-99 parts. The weight part of the surfactant in the preparation method is 1-5 parts.

[0057] According to a preferred embodiment, the nano-zirconia ceramic powder at least includes nano-zirconia particles and at least one ligand attached to the surface of at least one nano-zirconia particle. The ligand includes at least one or more of alkyl, cycloalkyl, aryl, heteroaryl, aralkyl, heteroaryl or heterocycloalkyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com