Machining process capable of improving concentricity of machined inner circle and machined outer circle of rotor

A technology of processing technology and concentricity, which is applied in the field of processing technology that can improve the concentricity of the inner and outer circles of rotor processing, can solve the problems of inability to guarantee the concentricity of the inner and outer circles of rotor processing, high product scrap rate and enterprise losses, and reduce product scrap rate , Product consistency is good, the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

[0041] In the picture:

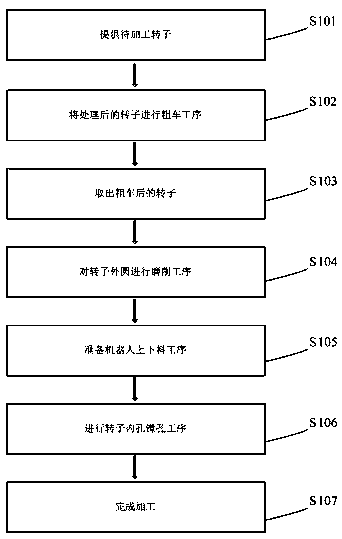

[0042] as attached figure 1 shown

[0043] A processing technology that can improve the concentricity of the inner and outer circles of rotor processing specifically includes the following steps:

[0044] S101: Provide the rotor to be processed, derust the surface, polish the surface with a scrub cloth, remove the oxide layer and dust, measure with a measuring ruler, and perform a cutting operation to complete the preliminary treatment process;

[0045] S102: Carry out the rough turning process of the processed rotor, carry out rough turning on the rotor through the CNC machine tool, remove most of the blank allowance, measure the diameter of the rotor with a vernier caliper, and determine whether it is semi-finish turning;

[0046] S103: After taking out the rough-turned rotor, semi-finish turning or direct finish turning can be carried out. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com