An embossing mechanism combining a pneumatic component with a connecting rod assembly

A technology of connecting rod components and pneumatic components, which is applied in relief decorations, decorative arts, etc., can solve the problems of embossing mechanism occupying space, complicated programming, poor versatility, etc., to save space, ensure horizontal effects, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

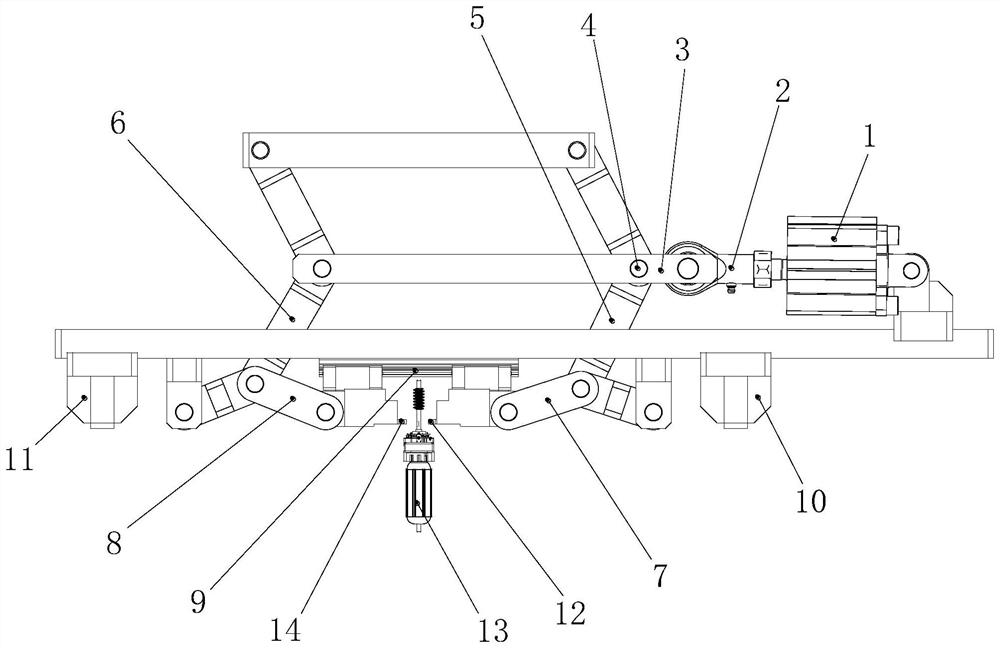

[0031] Embodiment one please refer to figure 1 , figure 2 , Figure 5 and Figure 8, an embossing mechanism in which a pneumatic element is combined with a connecting rod assembly, including a cylinder 1 and a table top, the cylinder 1 is fixedly mounted on the table top, the output end of the cylinder 1 is fixedly mounted with a connector 2, and on the connector 2 The driving rod 3 is fixedly connected, the connecting pin 4 is movably installed on the driving rod 3 and the connecting pin 4 can rotate freely on the driving rod 3, and the output connecting rod A5 is also movably connected on the connecting pin 4, and the output connecting rod A5 is also movably connected. The rod A5 is composed of two short rods, and the connecting pin 4 is arranged at the overlapping position of the two short rods. The two short rods of the output connecting rod A5 can rotate around the connecting pin 4 and the output connecting rod A5 passes through The connecting pin 4 is rotatably conne...

Embodiment 2

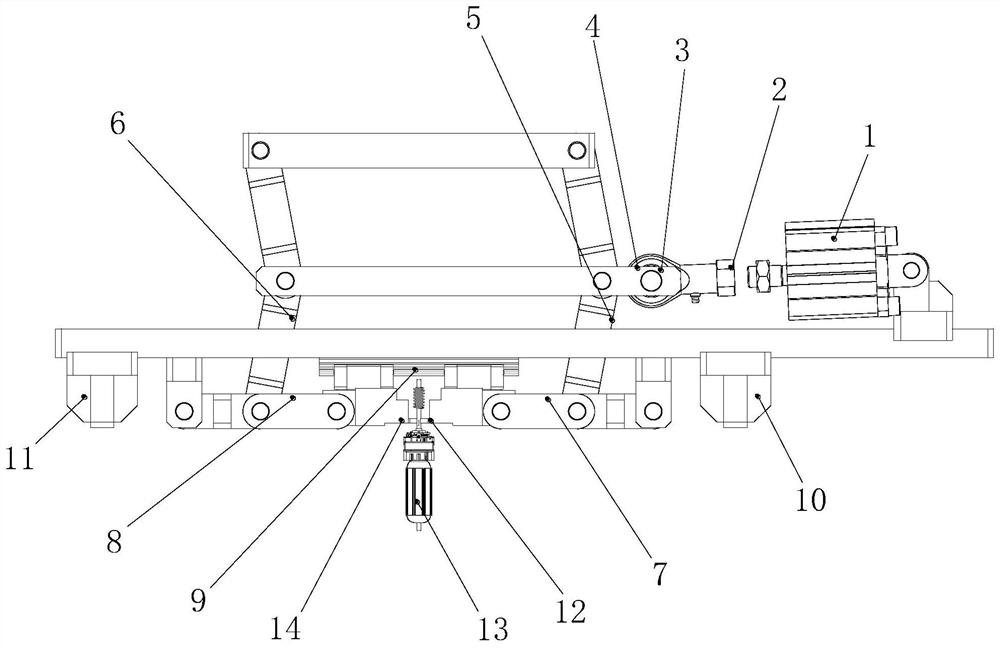

[0034] Embodiment 2 Please refer to image 3 , Figure 6 and Figure 8 , an embossing mechanism in which a pneumatic element is combined with a connecting rod assembly, including a cylinder 1 and a table top, the cylinder 1 is fixedly mounted on the table top, the output end of the cylinder 1 is fixedly mounted with a connector 2, and on the connector 2 The driving rod 3 is fixedly connected, the connecting pin 4 is movably installed on the driving rod 3 and the connecting pin 4 can rotate freely on the driving rod 3, and the output connecting rod A5 is also movably connected on the connecting pin 4, and the output connecting rod A5 is also movably connected. The rod A5 is composed of two short rods, and the connecting pin 4 is arranged at the overlapping position of the two short rods. The two short rods of the output connecting rod A5 can rotate around the connecting pin 4 and the output connecting rod A5 passes through The connecting pin 4 is rotatably connected with the ...

Embodiment 3

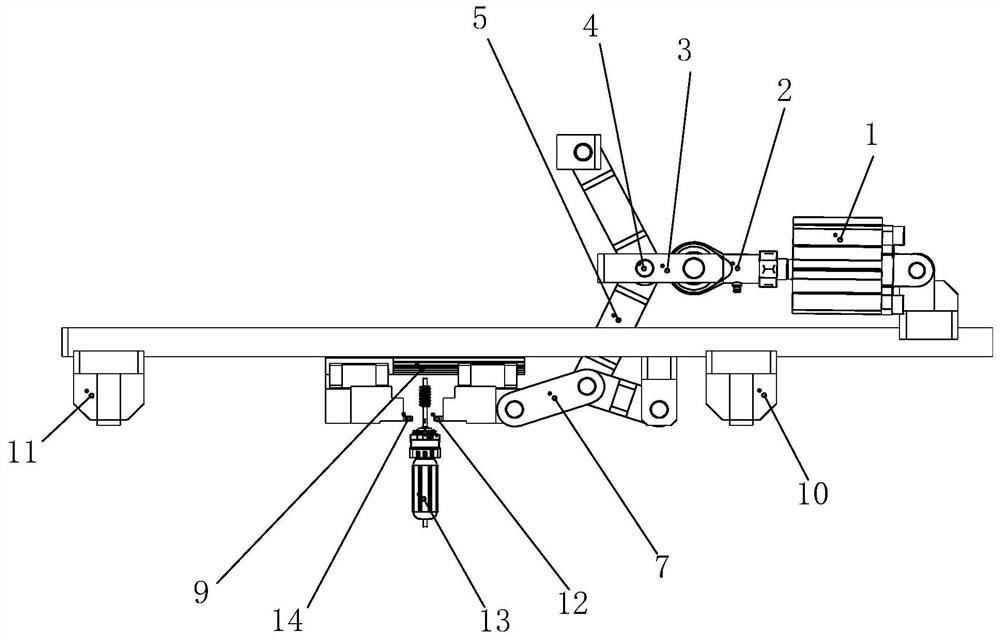

[0038] see Figure 4 , Figure 7 and Figure 8 , an embossing mechanism in which a pneumatic element is combined with a connecting rod assembly, including a cylinder 1 and a table top, the cylinder 1 is fixedly mounted on the table top, the output end of the cylinder 1 is fixedly mounted with a connector 2, and on the connector 2 The driving rod 3 is fixedly connected, the connecting pin 4 is movably installed on the driving rod 3 and the connecting pin 4 can rotate freely on the driving rod 3, and the output connecting rod A5 is also movably connected on the connecting pin 4, and the output connecting rod A5 is also movably connected. The rod A5 is composed of two short rods, and the connecting pin 4 is arranged at the overlapping position of the two short rods. The two short rods of the output connecting rod A5 can rotate around the connecting pin 4 and the output connecting rod A5 passes through The connecting pin 4 is rotatably connected with the driving rod 3, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com