Method for electrochemical deep removal of water-soluble extractant in tantalum liquid in potassium fluotantalate preparation process

A preparation process technology for potassium fluorotantalate, which is applied in the field of electrochemical deep removal of water-soluble extractant in tantalum liquid in the preparation process of potassium fluorotantalate, which can solve the problem that the preparation requirements of ultra-high purity tantalum cannot be met and the removal effect is not obvious , can not be removed and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

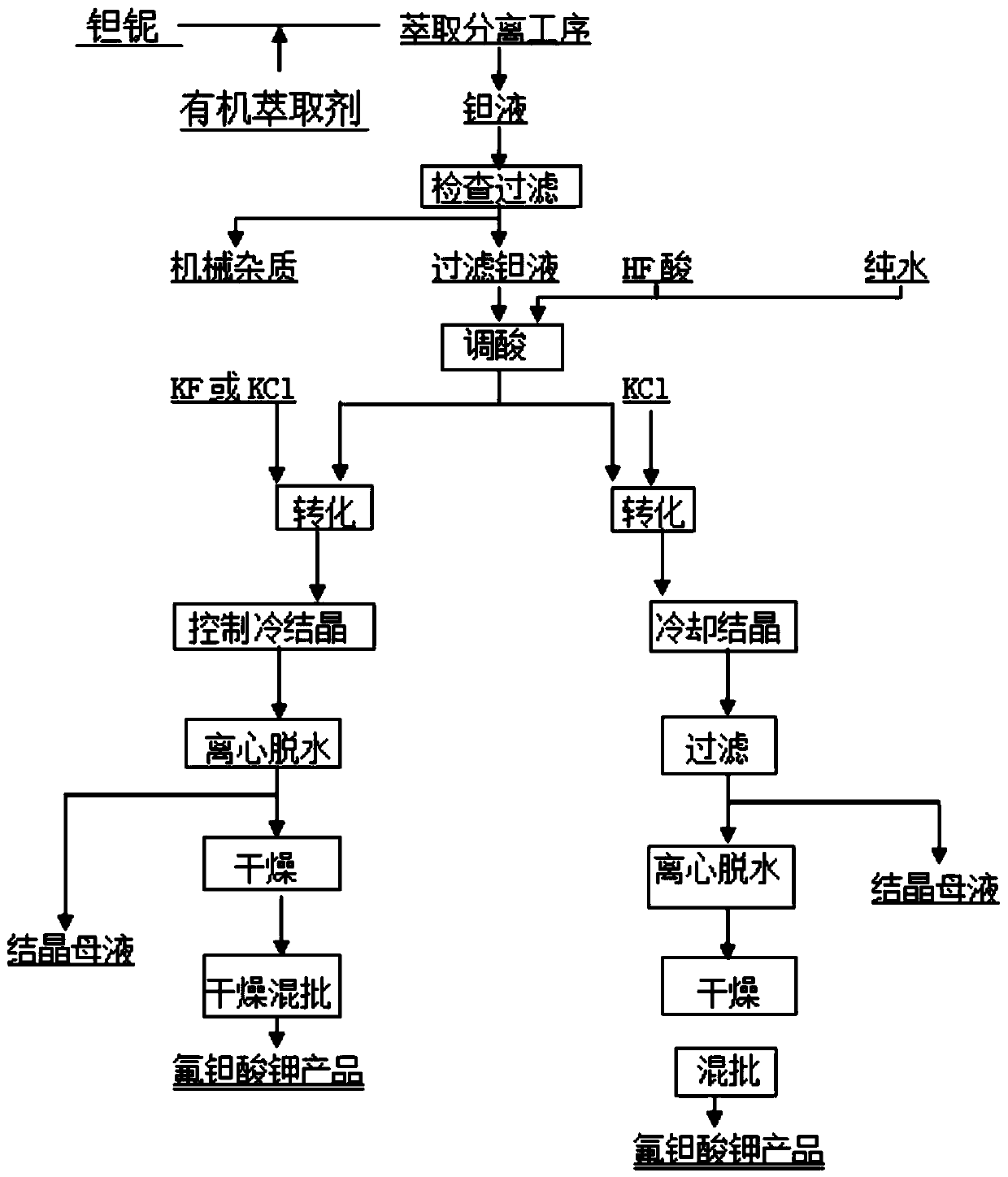

Image

Examples

Embodiment 1

[0026] In this embodiment, the experimental temperature is 30° C., the energization time is 2 hours, the flow rate of the air is 600 mL / min, and the voltage is 1.5V.

[0027] A method for electrochemically deeply removing water-soluble extractant from tantalum liquid in the preparation process of potassium fluorotantalate, comprising the following steps:

[0028] Step 1: Preparation

[0029] (1) get 50mL of tantalum liquid after extraction and separation in beaker, as sample stock solution, measure the content value of organic extractant in tantalum liquid before deep removal;

[0030] (2) place the tantalum liquid after extraction and separation in the reaction vessel lined with tetrahydrofuran, take two tantalum rods made of tantalum, one tantalum rod is used as cathode, and one tantalum rod is inserted into the tantalum liquid after extraction and separation as anode, An electric field with an electric field strength of 1.5V was applied between the cathode and the anode, a...

Embodiment 2

[0036] In this embodiment, the experimental temperature is 30° C., the energization time is 2 hours, the flow rate of the air is 600 mL / min, and the voltage is 3V.

[0037] A method for electrochemically deeply removing water-soluble extractant from tantalum liquid in the preparation process of potassium fluorotantalate, comprising the following steps:

[0038] Step 1: Preparation

[0039] (1) get 50mL of tantalum liquid after extraction and separation in beaker, as sample stock solution, measure the content value of organic extractant in tantalum liquid before deep removal;

[0040] (2) The tantalum liquid after extraction and separation is placed in a reaction vessel lined with metal tantalum, a tantalum rod made of tantalum is taken as the anode, the positive electrode of the power supply is connected to the tantalum rod, and the negative electrode of the power supply is connected to the reaction of the metal tantalum lining The container is used as the cathode, and the ta...

Embodiment 3

[0045] In this embodiment, the experimental temperature is 30°C, the energization time is 4 hours, the flow rate of the air is 600mL / min, and the voltage is 1.5V;

[0046] A method for electrochemically deeply removing water-soluble extractant from tantalum liquid in the preparation process of potassium fluorotantalate, comprising the following steps:

[0047] Step 1: Preparation

[0048] (1) get 50mL tantalum liquid after extraction and separation in beaker, as sample stock solution, measure the content value of organic extractant in the tantalum liquid before deep removal;

[0049](2) place the tantalum liquid after extraction and separation in the reaction vessel lined with tetrahydrofuran, take two tantalum rods made of tantalum, one tantalum rod is used as cathode, and one tantalum rod is inserted into the tantalum liquid after extraction and separation as anode, An electric field with an electric field strength of 1.5V was applied between the cathode and the anode, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com