Patents

Literature

41 results about "Potassium heptafluorotantalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium heptafluorotantalate is an inorganic compound with the formula K₂[TaF₇]. It is the potassium salt of the heptafluorotantalate anion [TaF₇]²⁻. This white, water-soluble solid is an intermediate in the purification of tantalum from its ores and is the precursor to the metal.

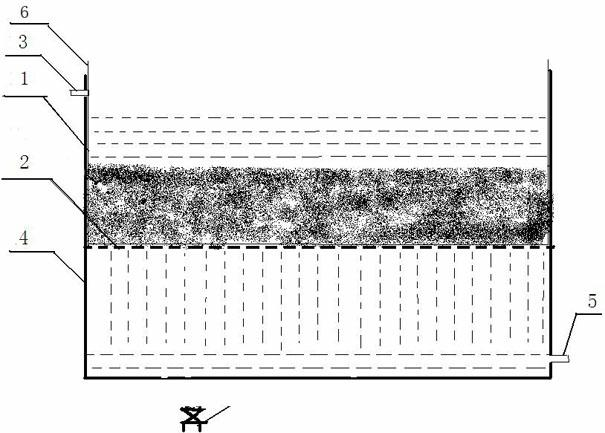

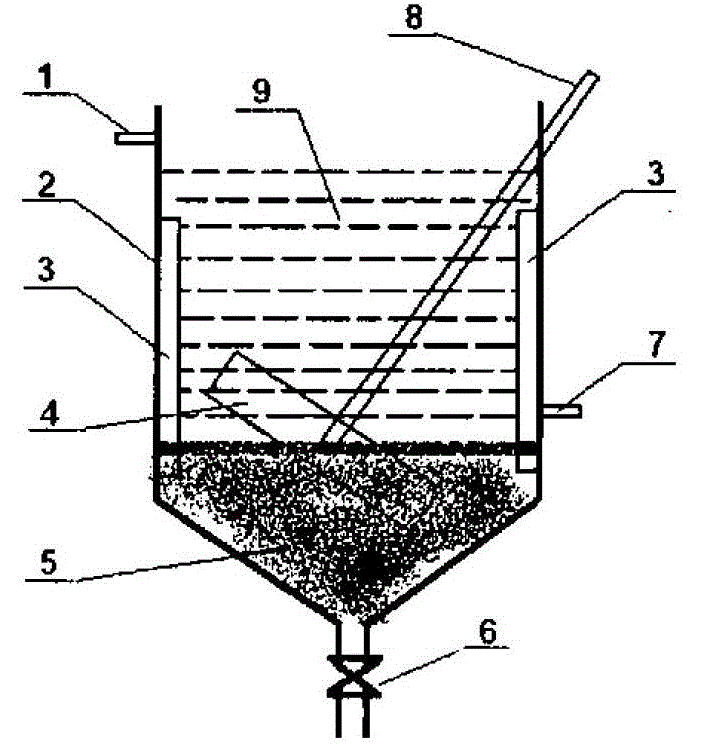

Rinsing method and device of potassium fluotantalate product obtained through sodium reduction

The invention relates to a rinsing method and device of a potassium fluotantalate product obtained through sodium reduction. The rinsing method comprises the following steps: using sodium to reduce potassium fluotantalate and obtain coagulum, crushing the coagulum, diafiltrating, rinsing, stirring to rinse, pickling, and drying to obtain raw tantalum powder. The obtained tantalum powder has high purity and good porosity and can be used to prepare condensed tantalum powder which is particularly suitable for the manufacture of the electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

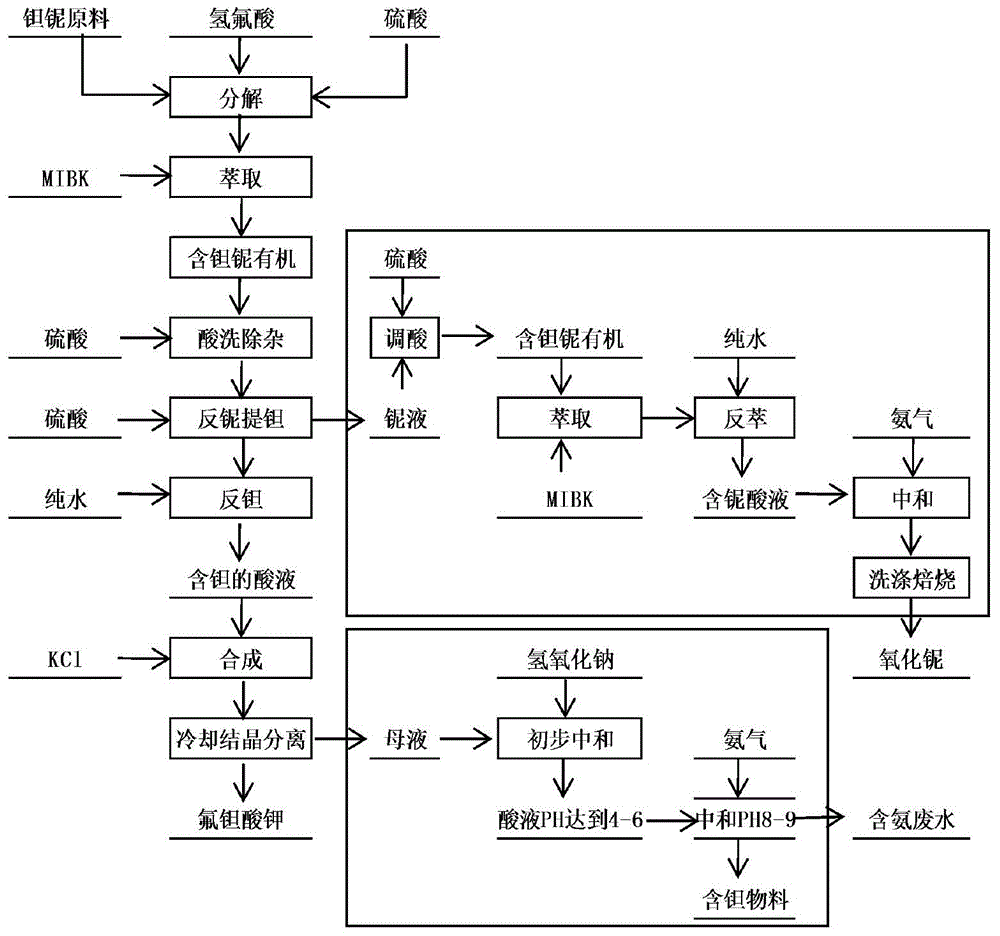

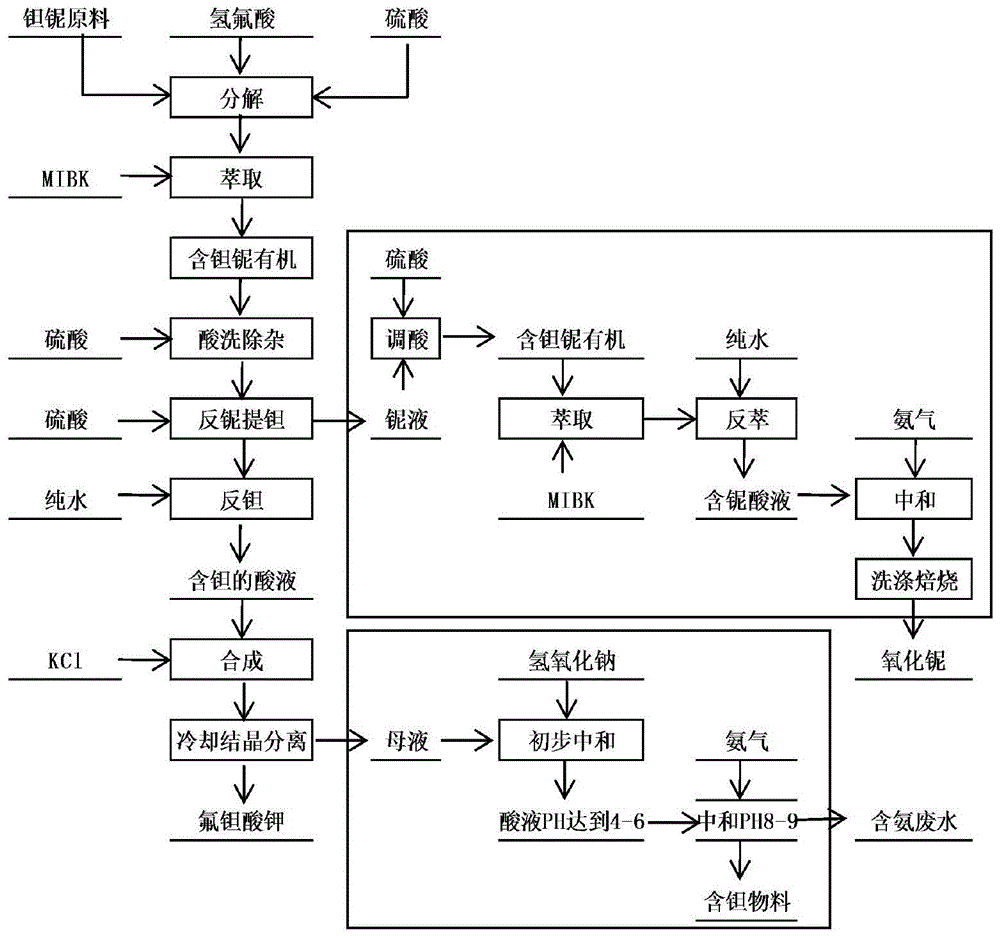

Method for reducing usage amount of ammonia gas during process of tantalum-niobium hydrometallurgical extraction

InactiveCN104480304AReduce acidityAcidity directly affects the reduction of the amount of ammonia usedProcess efficiency improvementFiltrationPotassium

The invention relates to a method for reducing usage amount of ammonia gas during the process of tantalum-niobium hydrometallurgical extraction. The method is as follows: 1, concentrated sulfuric acid is added into a niobium-containing acid solution to reduce acidity of the niobium-containing acid solution, and MIBK extraction, back-extraction, ammonia gas neutralization and the like are carried out to prepare a niobium oxide product; 2, as potassium fluotantalate is separated and extracted from a tantalum-containing acid solution by crystallization and filtration processes, a part of fluorotantalic acid is left in a mother liquor. In the prior art, ammonia gas must be utilized for neutralization and recovery. Thus, a lot of ammonia-containing wastewater is caused. According to the invention, part of alkaline matters (such as sodium hydroxide, magnesium hydrate, calcium hydroxide and the like) are used to replace ammonia gas and added into a mother liquor containing a fluorotantalic acid solution, and then ammonia gas is used for neutralization. Through the above two measures, the purpose of reducing consumption of ammonia gas and decreasing discharge of ammonia-containing wastewater is finally achieved.

Owner:NINGXIA ORIENT TANTALUM IND

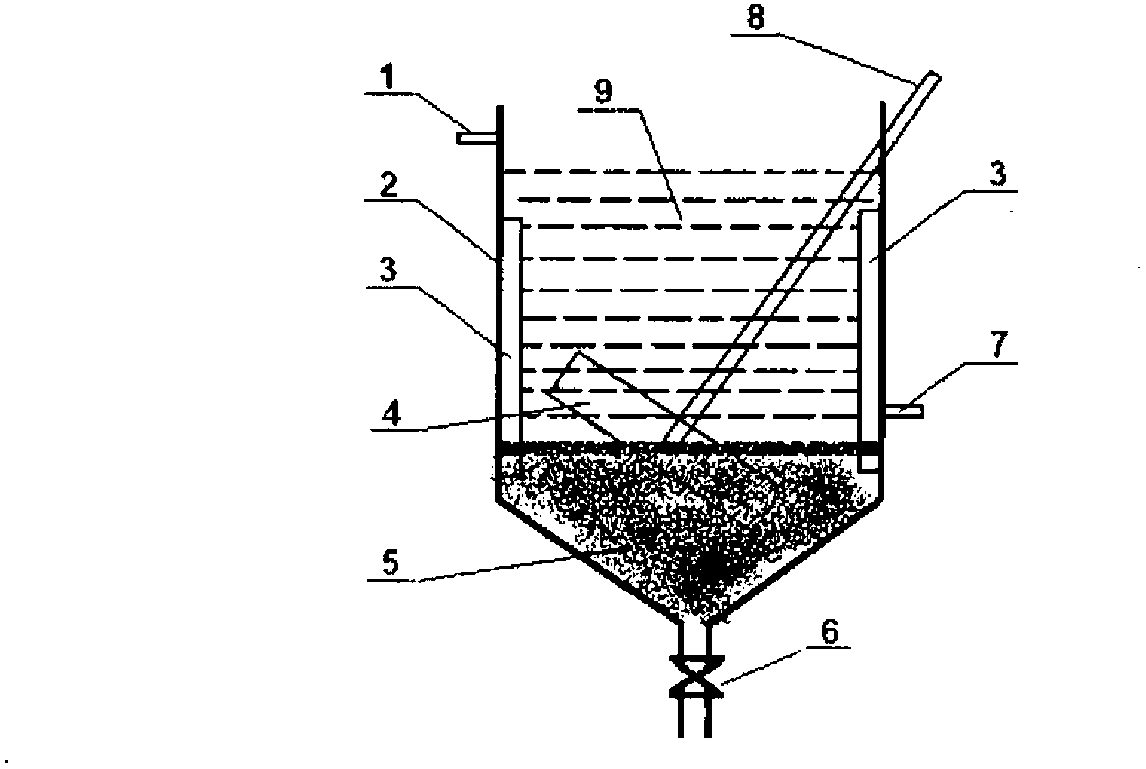

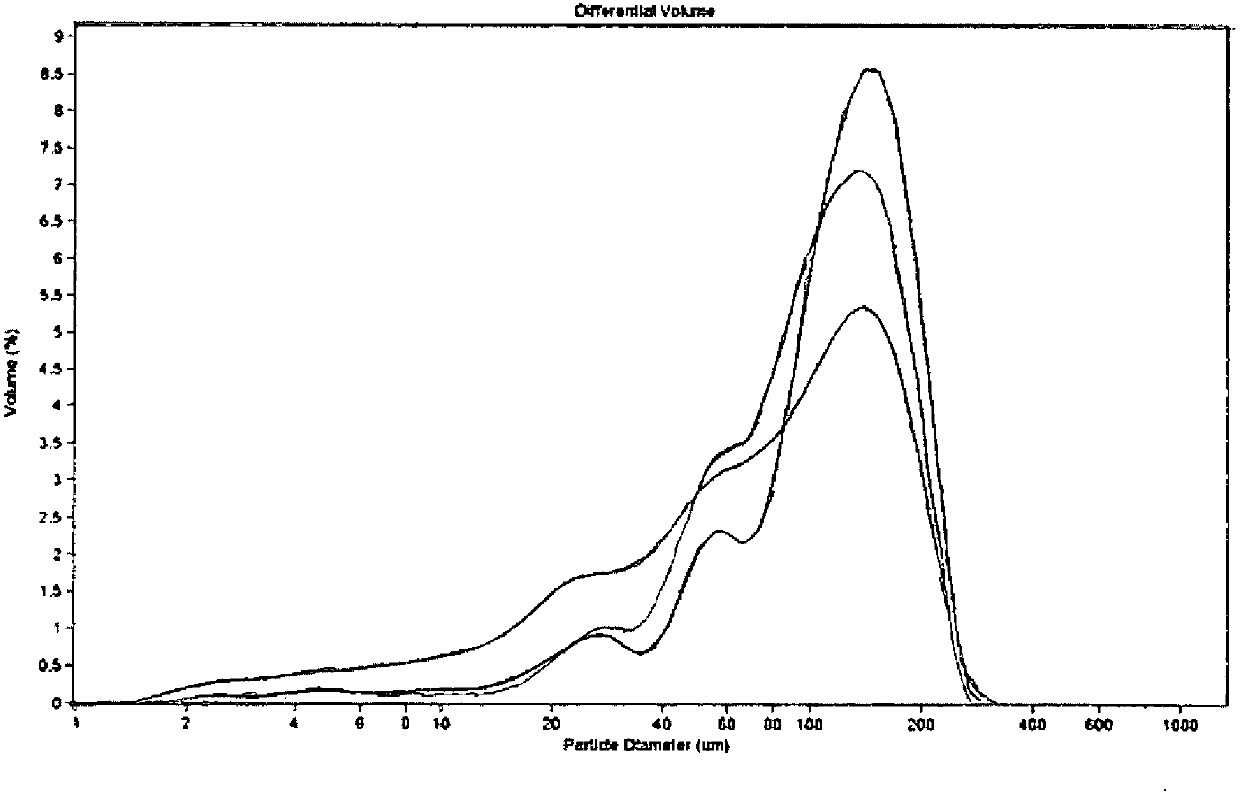

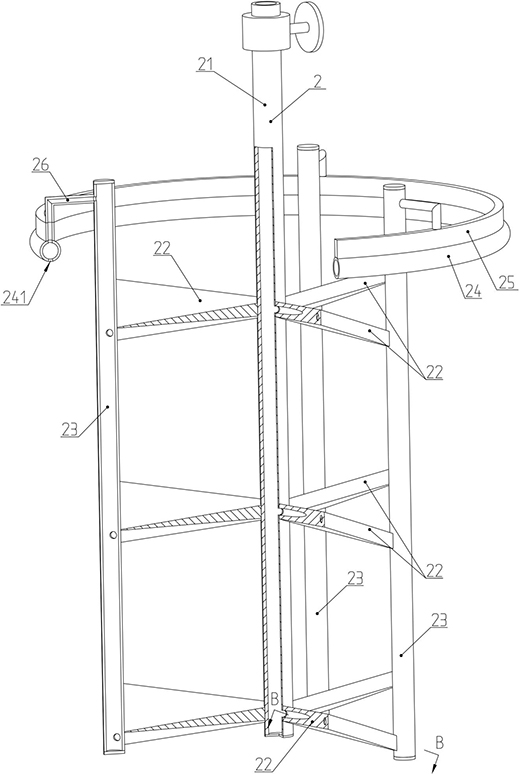

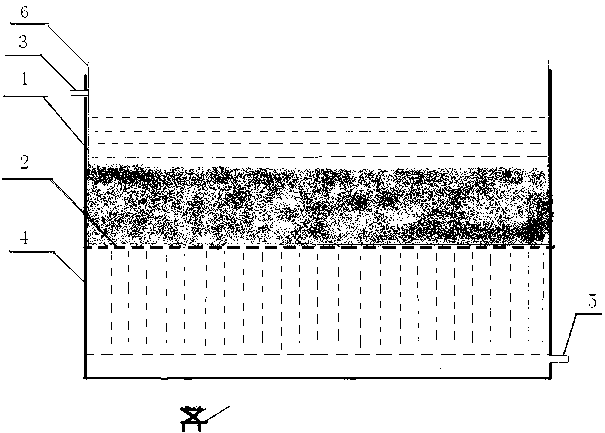

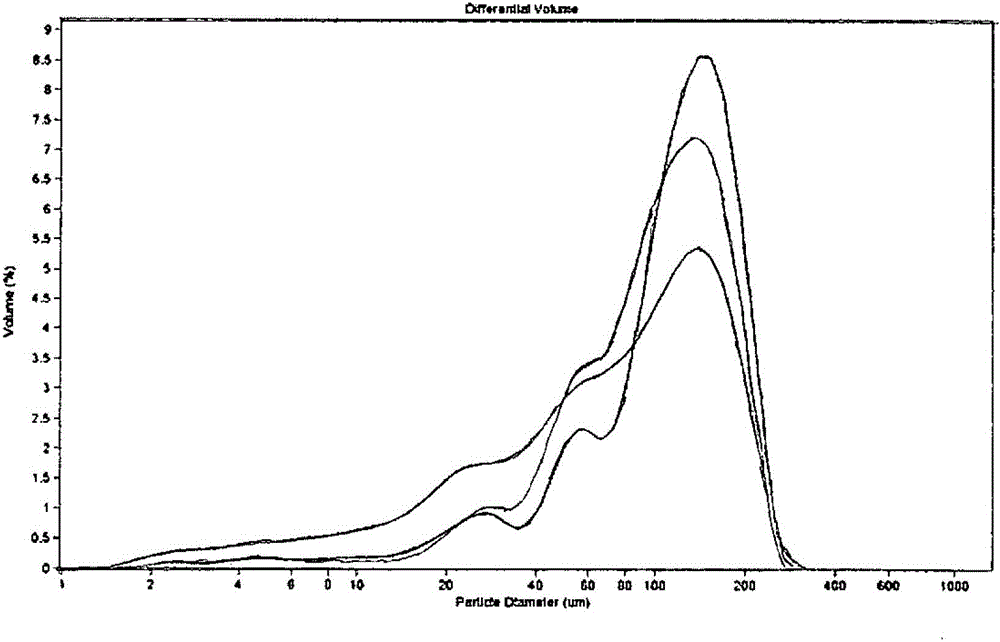

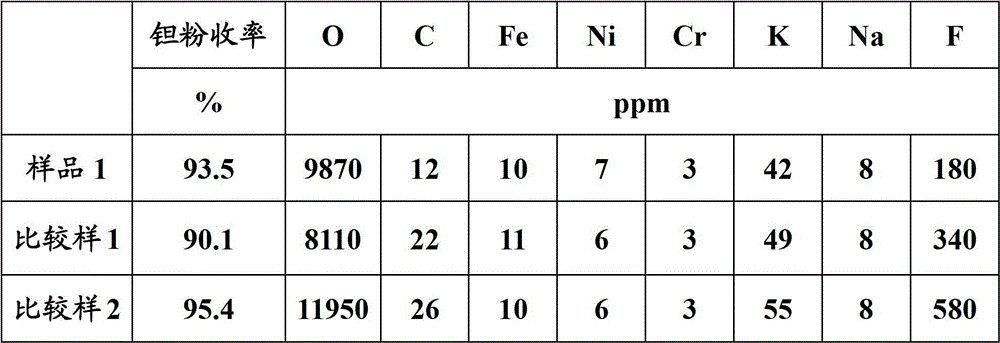

Stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium

The invention relates to a stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium. The water-washing method comprises the following steps of: performing stirring water-washing on the tantalum powder obtained by reducing potassium fluotantalate (K2TaF7) via metallic sodium (Na) which removes alkali metal haloids in an electrolyte solution, so as to remove harmful and indissolvable ultrafine-particle impurities in the tantalum powder; and then performing acid-washing and drying to obtain the initial tantalum powder. The method is high in the yield of tantalum powder; and the obtained tantalum powder is high in purity, good in particle size distribution and porosity, and especially suitable for manufacturing a tantalum electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

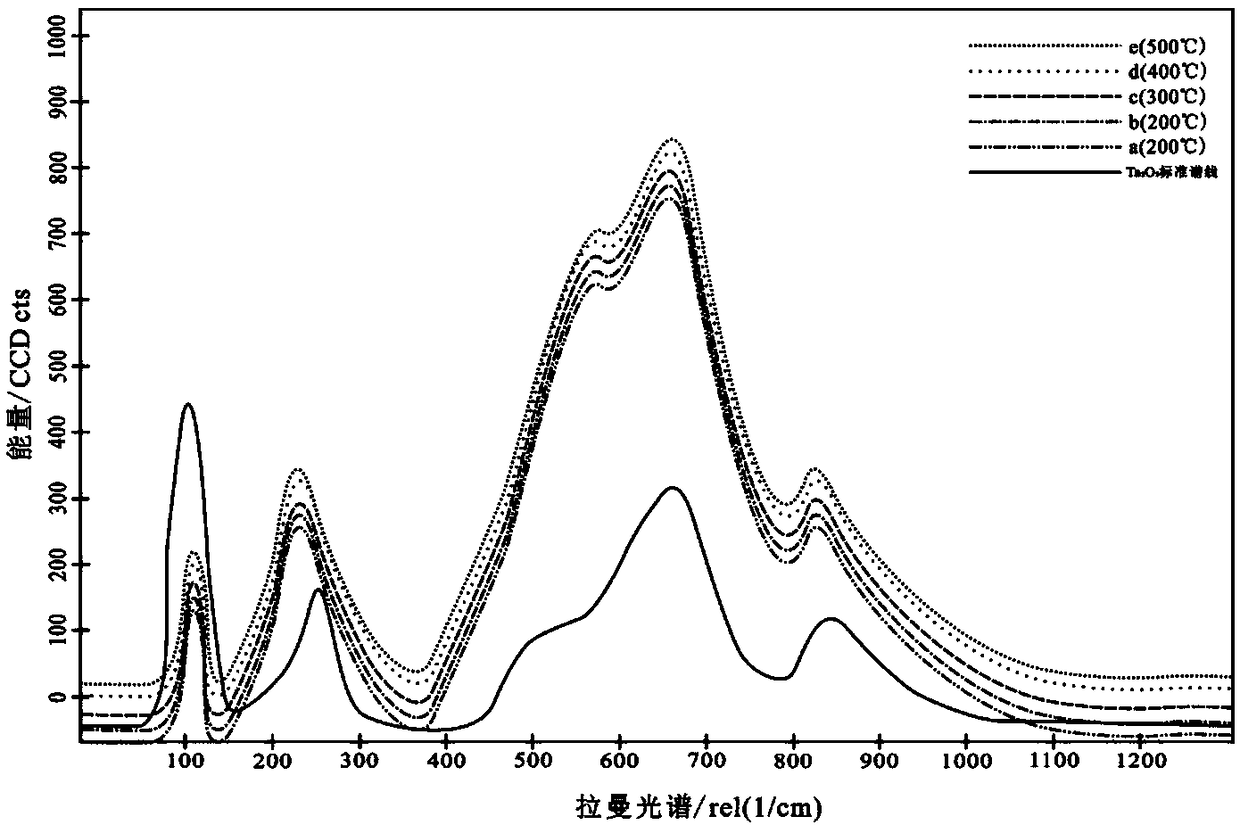

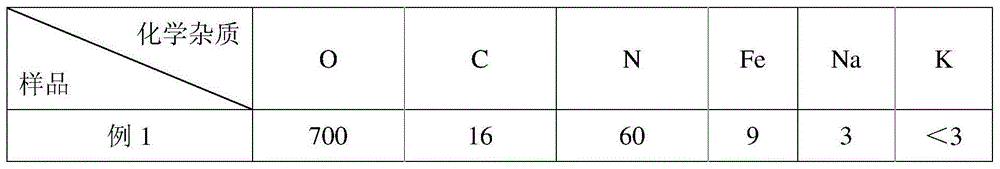

Method for preparing octahedral crystal form Ta2O5 nanoparticles through self-reaction of single reagent

InactiveCN108163892AAvoid using effectsAvoid process problemsTantalum compoundsNanotechnologyPotassiumHydrolysis

The invention discloses a method for preparing octahedral crystal form Ta2O5 nanoparticles through self-reaction of a single reagent. The method comprises the following steps that 1, potassium fluotantalate powder is selected and dissolved in water, and the potassium fluotantalate solution is placed in a pretreated precious metal pipe and sealed; 2, the sealed precious metal pipe is placed in a hydrothermal reaction kettle and sealed, the temperature inside the hydrothermal reaction kettle is adjusted to be 200-500 DEG C, inert gas or deionized water is adopted for adjusting the pressure inside the hydrothermal reaction kettle to be 50-200 MPa, a hydrolysis reaction is carried out for 12-24 h, and the reaction kettle is cooled to indoor temperature after the reaction is finished; 3, the hydrothermal reaction kettle is opened, the reacted precious metal pipe is taken out and opened, solution residue is recycled, samples are collected, washed and dried, and therefore the octahedral crystal form Ta2O5 nanoparticles are obtained. In the method, the single reagent is adopted as a synthesis raw material, the cost is low, energy consumption is low, pollution is avoided, and the prepared Ta2O5 nanoparticles are intact in crystal form and are in an octahedral shape.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method for silicon carbide particle reinforced aluminum-based composite material

InactiveCN105463265AImprove permeabilityImprove technical problems such as poor wettabilityPotassiumFluosilicates

The invention discloses a preparation method for a silicon carbide particle reinforced aluminum-based composite material, and relates to the field of aluminum-based composite materials. The preparation method comprises the operating steps that 1, silicon carbide powder and particles and potassium fluotitanate, or potassium fluozirconate, or potassium fluoborate, or potassium fluosilicate or potassium fluotantalate serve as powder materials, and two kinds or several kinds of the powder materials are uniformly mixed; and 2, aluminum in a furnace is melted, after the aluminum is heated up to 660 DEGC-1500 DEG C, the mixed pulverized raw material is added into the furnace, melt is fully stirred, heat preserving is conducted, and after slagging-off is conducted on the melt, the fully stirred melt is casted into a variety of products. According to the preparation method for the silicon carbide particle reinforced aluminum-based composite material, the performance of the aluminum-based composite material is effectively improved, the process is simple, operating is convenient, the cost is low, and industrial production can be achieved.

Owner:周凡

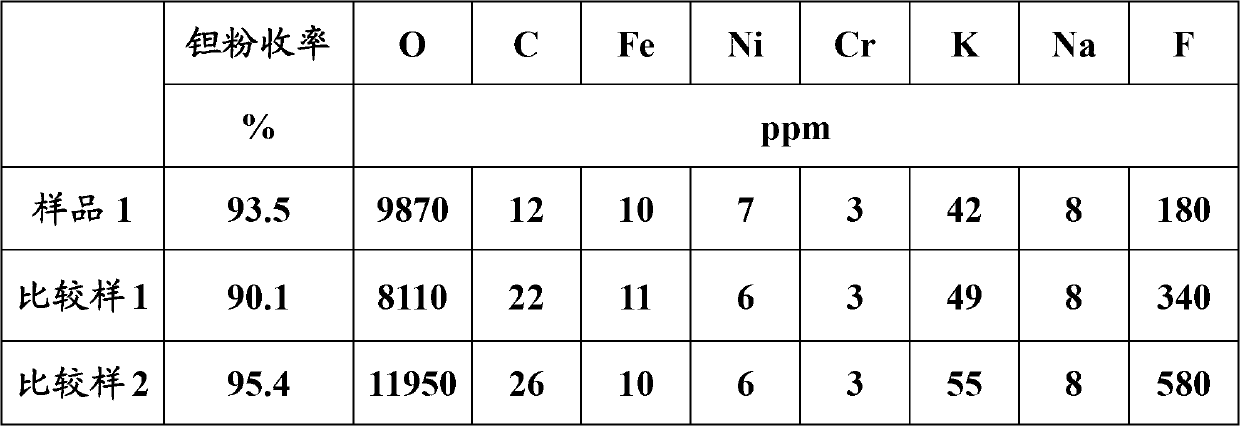

Method for preparing target-level high-purity tantalum powder

The invention relates to a method for preparing target-level high-purity tantalum powder. According to the method for preparing the target-level high-purity tantalum powder, a block-shaped mixture of tantalum powder prepared through potassium fluotantalate sodium reduction and one or more of diluted slats including NaCl, KCl and KF is filtered and washed with pure water, when the conductivity of filtering and washing liquid is smaller than 5000 us / cm, the filtered and washed mixture is poured into a horizontal type ball mine for wet-type ball milling, the mixture is taken out, acid pickling, suction filtration and drying are conducted on the mixture, so that raw tantalum powder is obtained, thermal treatment, oxygen reduction, oxygen-reduction acid pickling, secondary drying and detection are conducted on the raw tantalum powder, and then the target-level high-purity tantalum powder is obtained. According to the method for preparing target-level high-purity tantalum powder, the technology is simple, the production cost is low, the tantalum powder prepared according to the method is large in apparent density, high in purity, low in oxygen content and capable of meeting the requirement of a target for the purity and the density of materials, and therefore tantalum target cost and tantalum alloy target cost are greatly reduced.

Owner:NINGXIA ORIENT TANTALUM IND +1

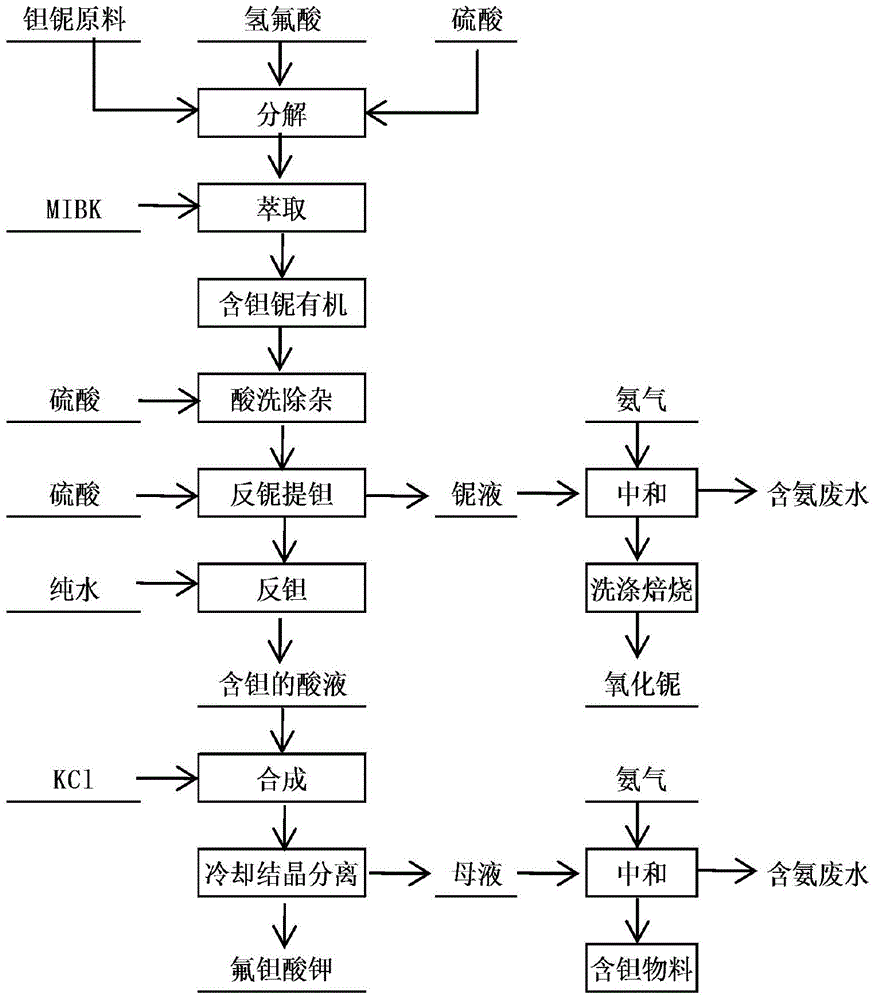

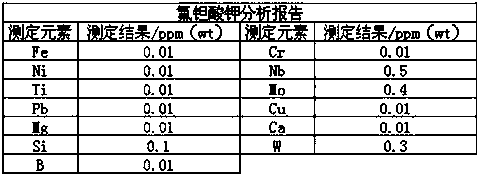

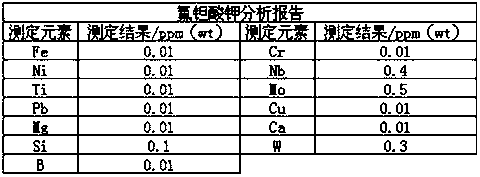

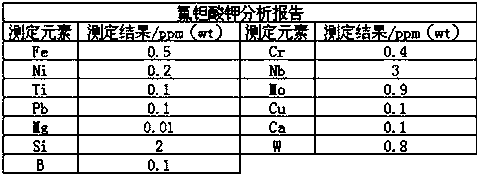

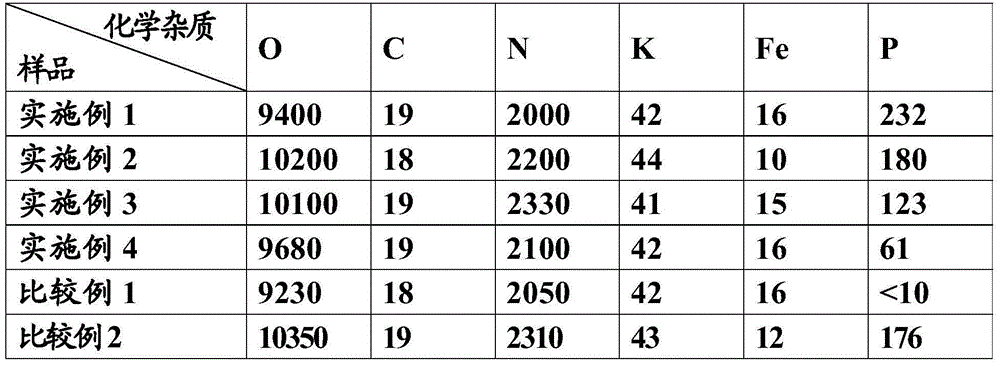

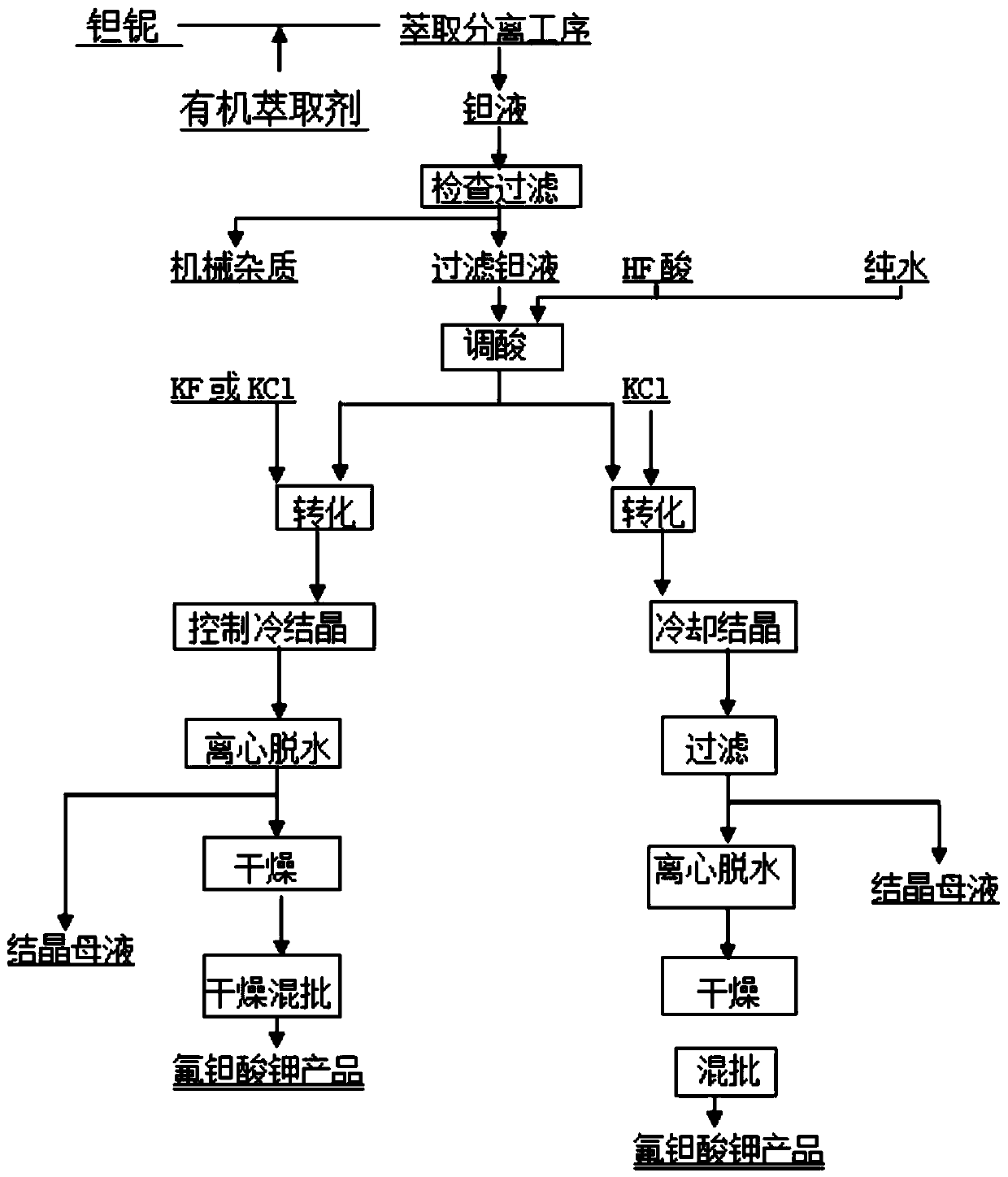

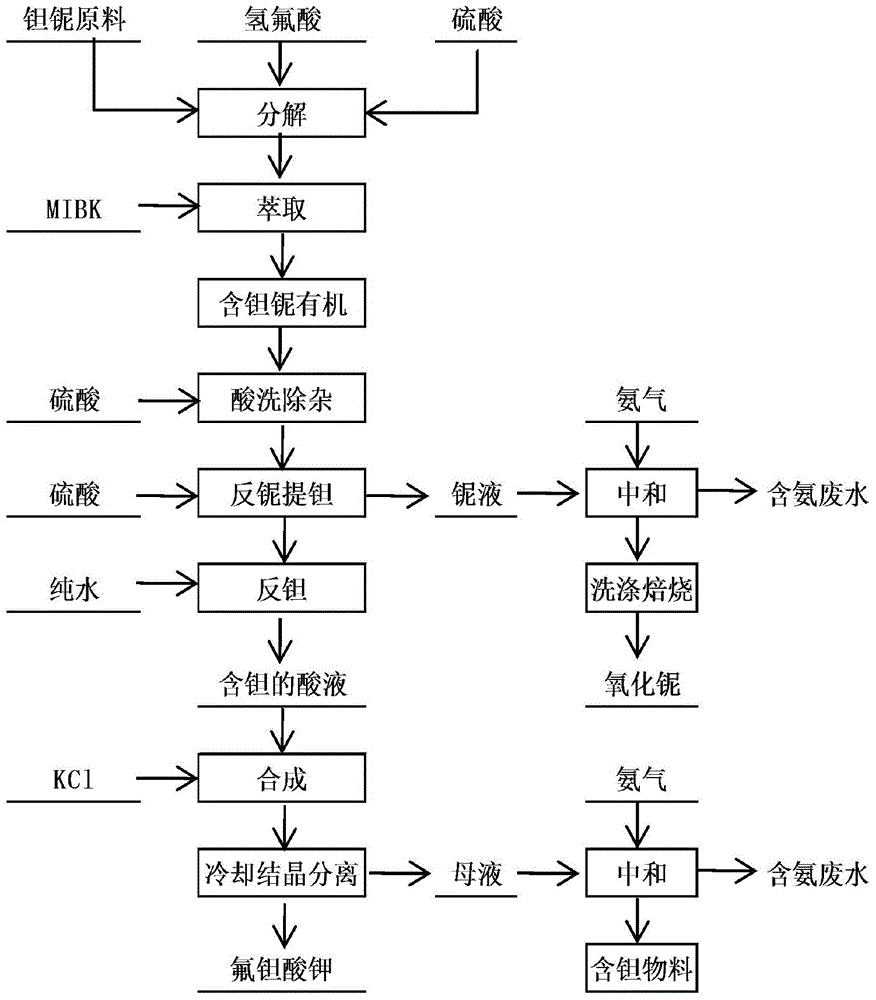

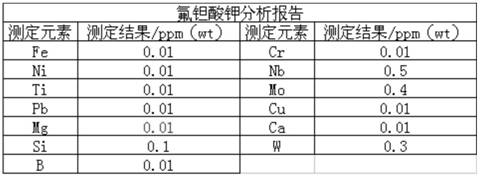

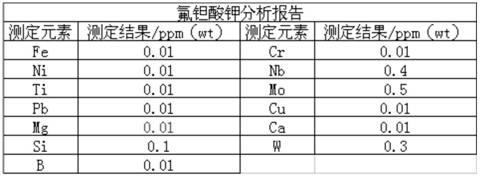

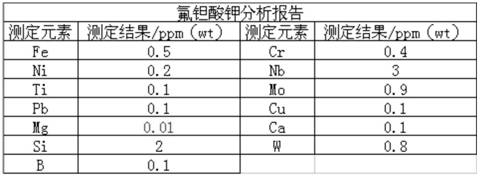

Preparation method of high-purity potassium fluorotantalate

The invention relates to a preparation method of high-purity potassium fluorotantalate. The preparation method is characterized by comprising the following steps: (1) decomposition: adding tantalum-niobium mineral into hydrofluoric acid and sulfuric acid for decomposition; (2) mineral-pulp extraction: utilizing an MIBK (Methyl Isobutyl Ketone) solvent or sec-octyl alcohol solvent to carry out backflow extraction and extracting fluorine-niobium acid and fluorine-tantalum acid into the solvent; (3) acid pickling: adopting sulfuric-acid solution to be contacted with the solvent obtained after extraction of step (2) in a backflow manner; (4) tantalum extraction by back extraction of niobium: utilizing the sulfuric-acid solution and the obtained solvent to carry out backflow extraction in an extraction groove, extracting the fluorine-niobium acid into an aqueous phase and forming fluorine-niobium acid aqueous solution; (5) back extraction of tantalum: placing the remaining organic solutionin another extraction groove, utilizing pure water to carry out back extraction on fluorine-tantalum acid organic solution into the pure water and forming fluorine-tantalum acid aqueous solution; (6)synthesis; (7) cooling and crystallization. The method for preparing high-purity potassium fluorotantalate by a method of sectional back extraction and sectional crystallization has the beneficial effect that impurities in the potassium fluorotantalate can be effectively removed.

Owner:NINGXIA ORIENT TANTALUM IND

Preparation method for aluminum matrix composite material

InactiveCN105734334AImprove permeabilityImprove technical problems such as poor wettabilityPotassiumFluosilicates

The invention discloses a preparation method for an aluminum matrix composite material, and relates to the field of the aluminum matrix composite material. The operation method includes the steps that two or several kinds of diamond or diamond and silicon carbide mixed powder particles and potassium fluotitanate or potassium fluozirconate or potassium fluoborate or potassium fluosilicate orpotassium fluotantalate are evenly mixed; aluminum in a furnace is melted, the temperature rises to 660 DEG C to 1500 DEG C, and mixed powdery raw materials are added into the furnace to be sufficiently stirred; and after melting liquid is subject to heat preservation, drossing is carried out on the melting liquid, and the sufficiently-mixed melting liquid is cast into various products. According to the preparation method, the performance of the aluminum matrix composite material is effectively improved, the process is simple and convenient, the operation cost is low, and industrial production can be achieved.

Owner:周凡

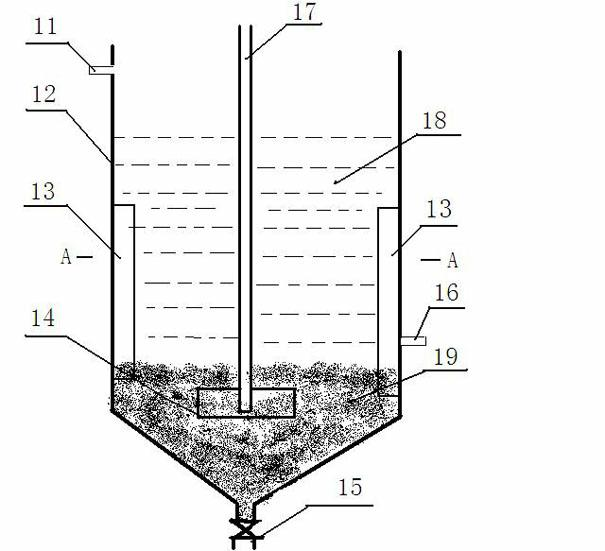

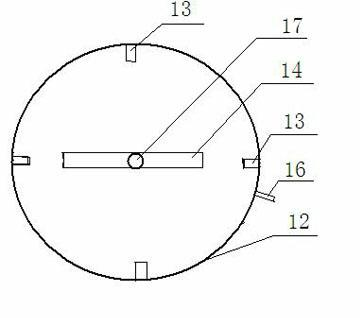

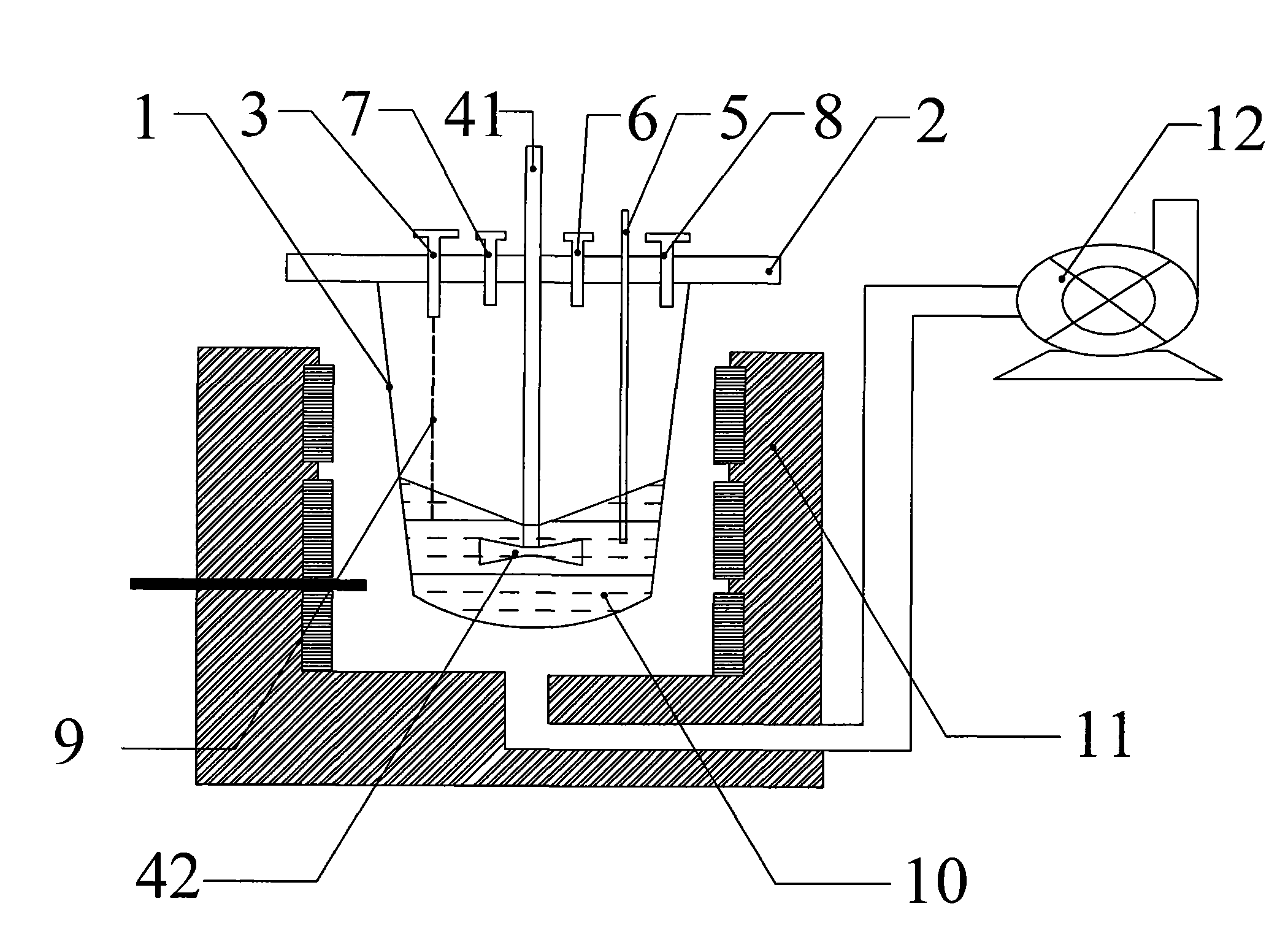

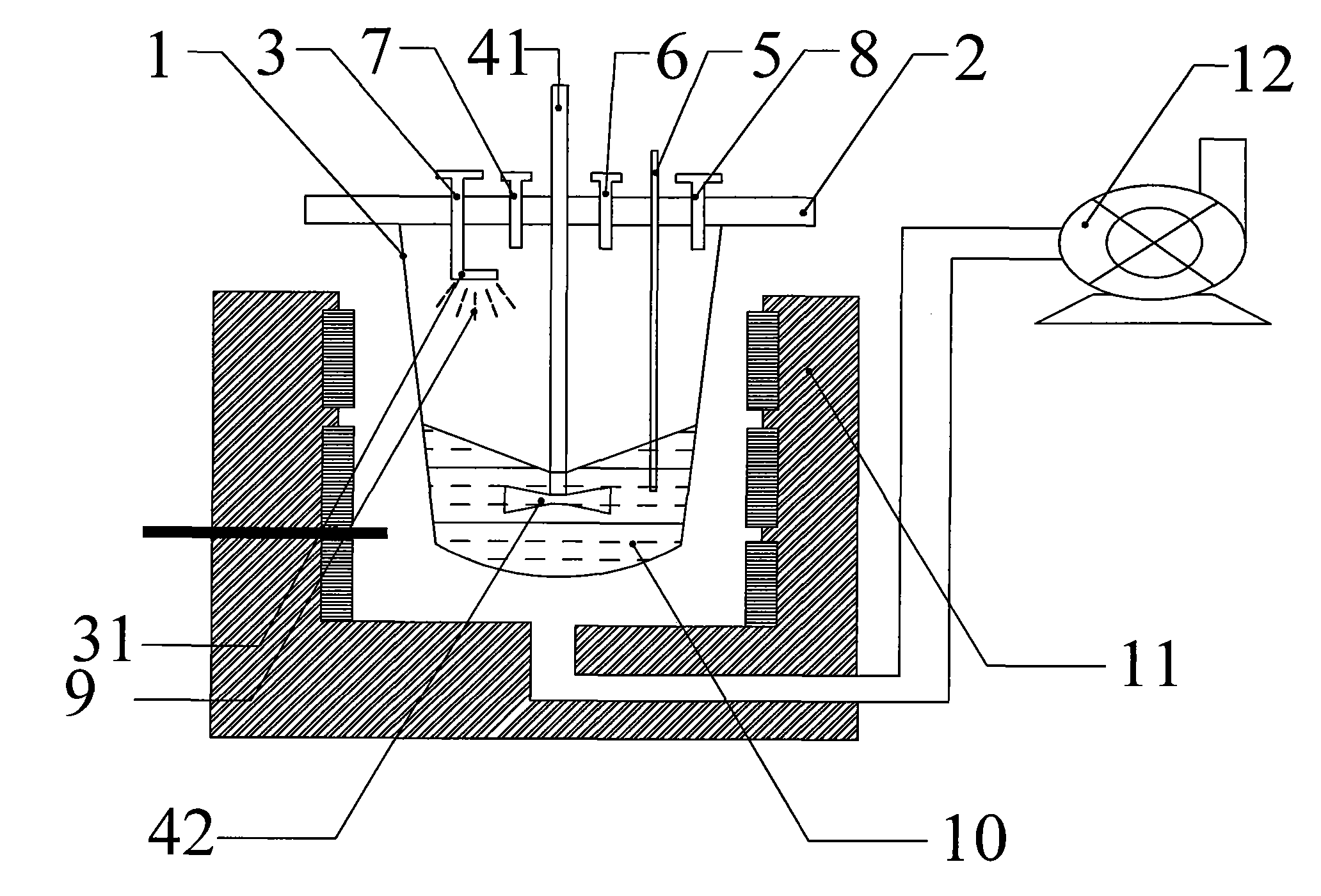

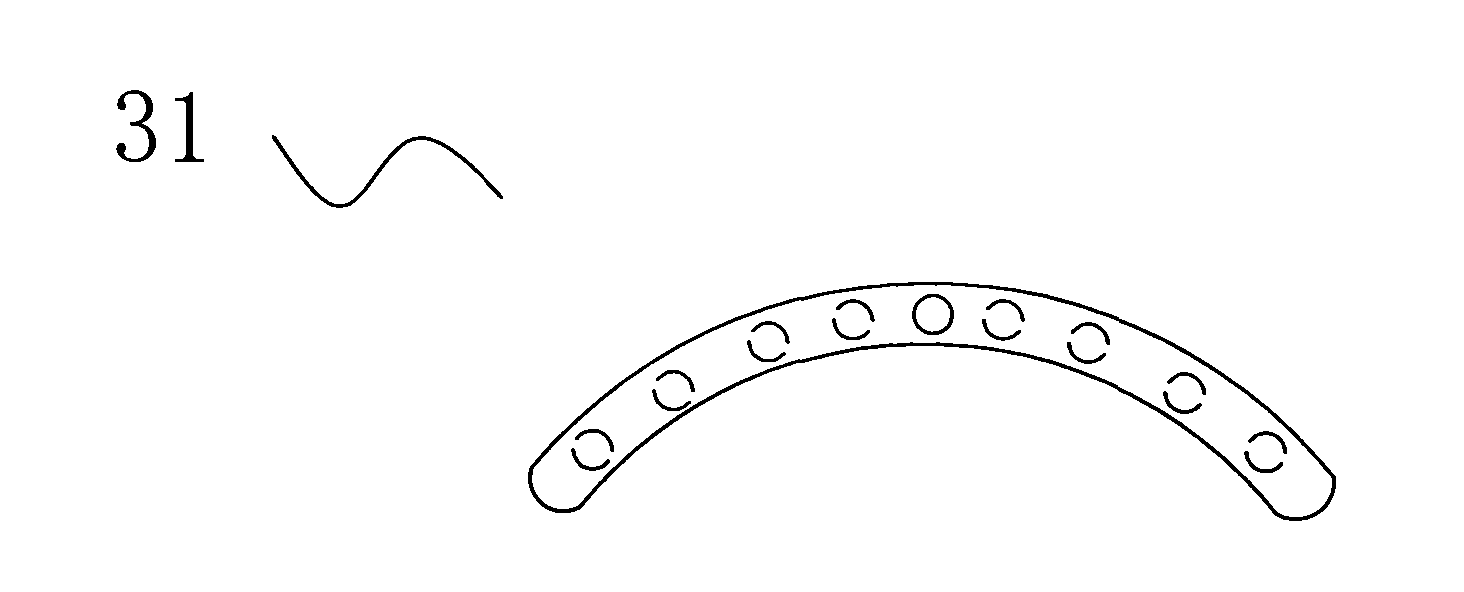

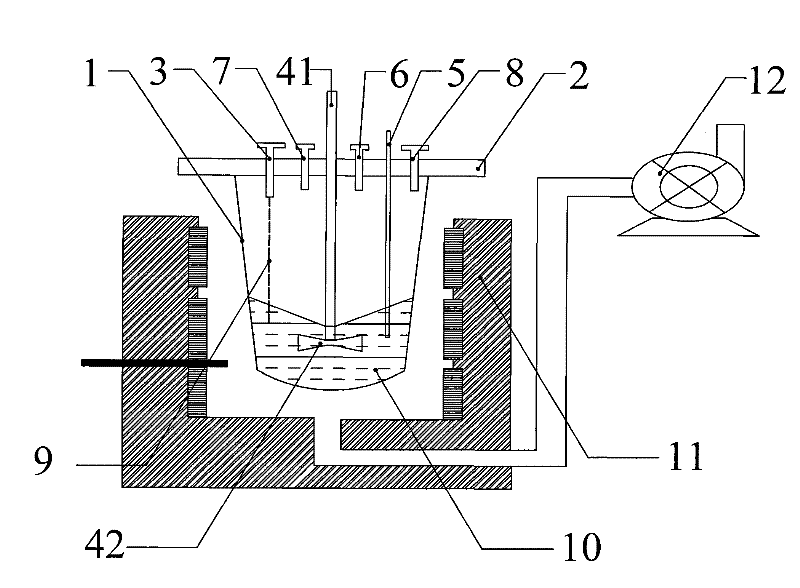

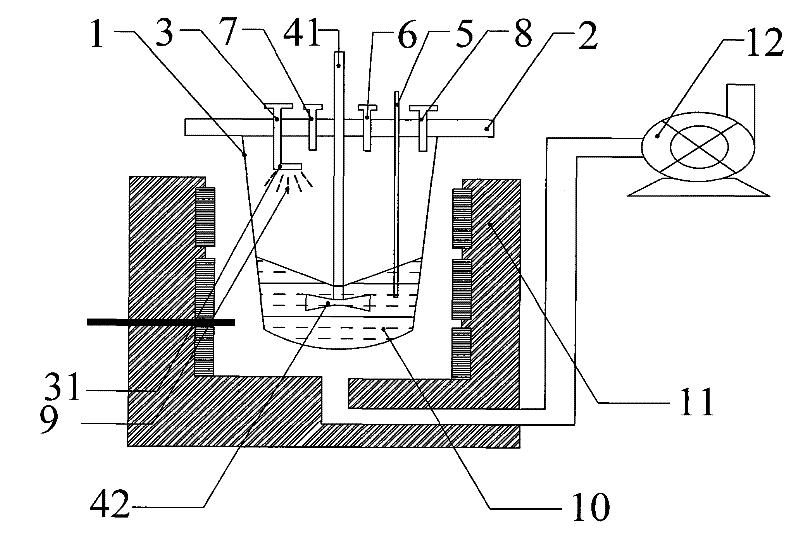

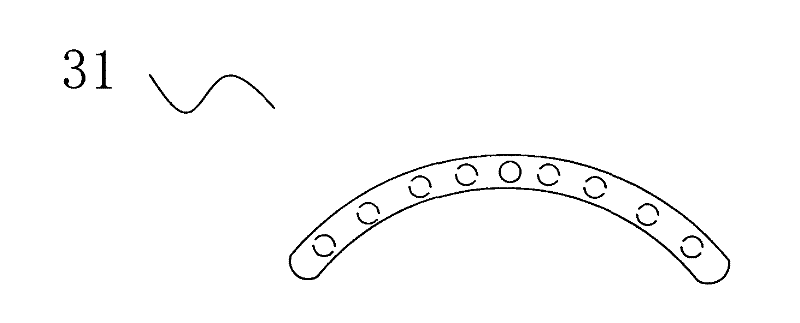

Method and device for preparing tantalum powder by stirring sodium and reducing potassium fluotantalate

The invention discloses a device for preparing tantalum powder by stirring sodium and reducing potassium fluotantalate, which comprises a reaction vessel and a reaction vessel cover, wherein the reaction vessel is hermetically sealed with the reaction vessel cover; the reaction vessel cover is provided with a plurality of through holes; the through holes are respectively provided with a thermocouple, a stirring apparatus and a sodium injection tube; the reaction vessel cover is further provided with a feed inlet, an air inlet and an air outlet; and the reaction vessel is provided with a sodium distributor. The invention further discloses a method for preparing the tantalum powder using the device. In the invention, metal sodium is injected into the reaction vessel in a dispersive manner by the sodium distributor, and the prepared tantalum powder has uniformly-distributed elementary particles.

Owner:江门富祥电子材料有限公司

Method and device for preparing tantalum powder by stirring sodium and reducing potassium fluotantalate

The invention discloses a device for preparing tantalum powder by stirring sodium and reducing potassium fluotantalate, which comprises a reaction vessel and a reaction vessel cover, wherein the reaction vessel is hermetically sealed with the reaction vessel cover; the reaction vessel cover is provided with a plurality of through holes; the through holes are respectively provided with a thermocouple, a stirring apparatus and a sodium injection tube; the reaction vessel cover is further provided with a feed inlet, an air inlet and an air outlet; and the reaction vessel is provided with a sodium distributor. The invention further discloses a method for preparing the tantalum powder using the device. In the invention, metal sodium is injected into the reaction vessel in a dispersive manner by the sodium distributor, and the prepared tantalum powder has uniformly-distributed elementary particles.

Owner:江门富祥电子材料有限公司

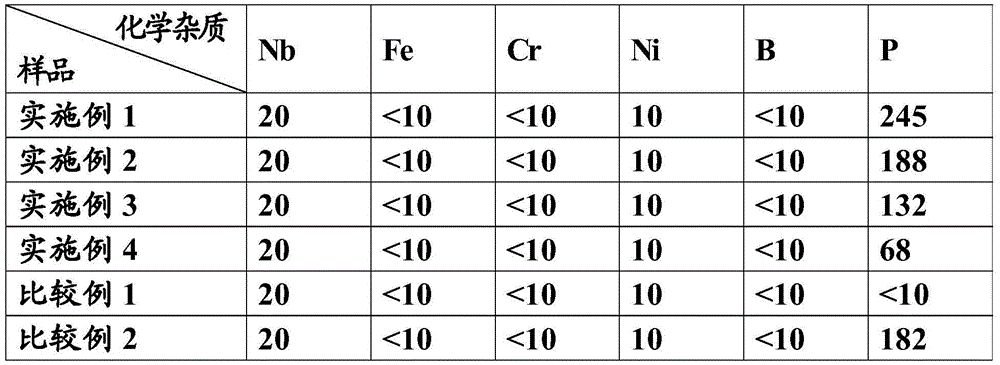

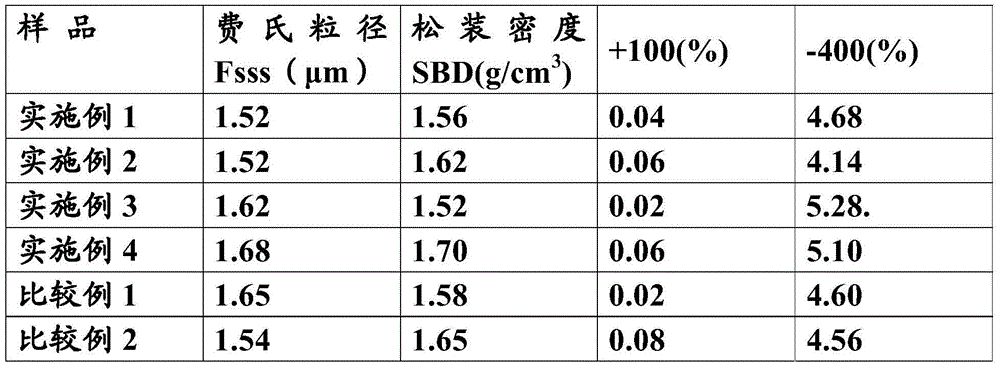

Preparation method of phosphorus-containing tantalum powder

The invention relates to a preparation method of a phosphorus-containing tantalum powder and a phosphorus-containing tantalum powder prepared by the method, and a preparation method of phosphorus-containing potassium tantalifluoride and phosphorus-containing potassium tantalifluoride prepared by the method. According to the method, a phosphorus-containing compound is added into a potassium tantalifluoride synthesis solution, and an acid leaching process is utilized to synthesize the potassium tantalifluoride from columbite-tantalite ore powder; and the phosphorus-containing potassium tantalifluoride is prepared into the phosphorus-containing tantalum powder. The phosphorus doping process of the phosphorus-containing tantalum powder is performed in the potassium tantalifluoride synthesis process, so the phosphorus is distributed more uniformly on the tantalum powder particles; since the phosphorus is doped in the potassium tantalifluoride synthesis process, the generation of primary particles is directly influenced; and thus, the primary particles are finer and have larger specific area, and the tantalum powder has higher specific capacity, thereby satisfying the requirement of the capacitor product for the specific capacity of the tantalum powder.

Owner:NINGXIA ORIENT TANTALUM IND +1

Axial-flow fan of automobile air conditioner and preparation method thereof

The invention discloses an axial-flow fan of an automobile air conditioner and a preparation method thereof. The preparation method comprises the following steps: 1) blending and mixing PC (polycarbonate), ASA (acrylonitrile styrene acrylate copolymer), CPE (chlorinated polyethylene), p-tert-butylphenol-formaldehyde resin, nano titanium dioxide, tungsten disulfide, calcium naphthenate, aspartic acid, tributyl citrate, triethylene tetramine, diazolidinyl urea, diatomite, carbon fibers, ethyl cellulose, boron nitride, potassium fluotantalate, diborane and silane coupling agents to form a mixture; and 2) curing the mixture, thus preparing the axial-flow fan of the automobile air conditioner. The automobile air conditioner prepared by the method has excellent mechanical properties. Meanwhile, the method is simple in steps and raw materials are easy to obtain.

Owner:WUHU DEXIN AUTO PARTS

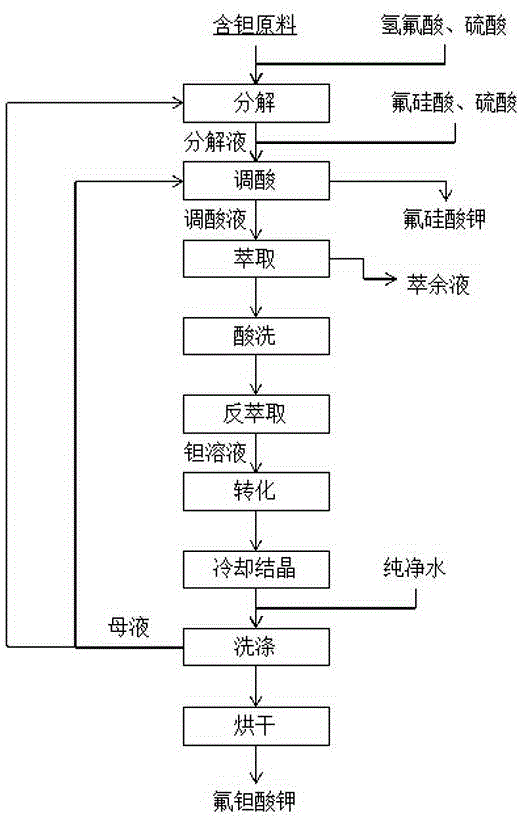

Method for preparing potassium fluotantalate

The invention relates to a preparation method of potassium fluotantalate. In the method, potassium fluotantalate is prepared by a mother liquid internal-circulation process instead of the crystallized mother liquid in recycling treatment of a liquid ammonia neutralizing process; the mother liquid instead of water is sufficiently decomposed with hydrofluoric acid and sulfuric acid; then fluorosilicic acid, sulfuric acid and mother liquid are added for low-acid blending and low-acid extraction; potassium fluotantalate is obtained through transformation and cooling crystallization. According to the method provided by the invention, the use of liquid ammonia is abandoned, and the pollution of ammonia nitrogen is reduced from the source; compared with the traditional process, the discharge of wastewater and the dosage of hydrofluoric acid are greatly reduced, the recycling of industrial potassium fluorosilicate from the mother liquid is realized, and the recycling rate of potassium fluotantalate is as high as 98%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

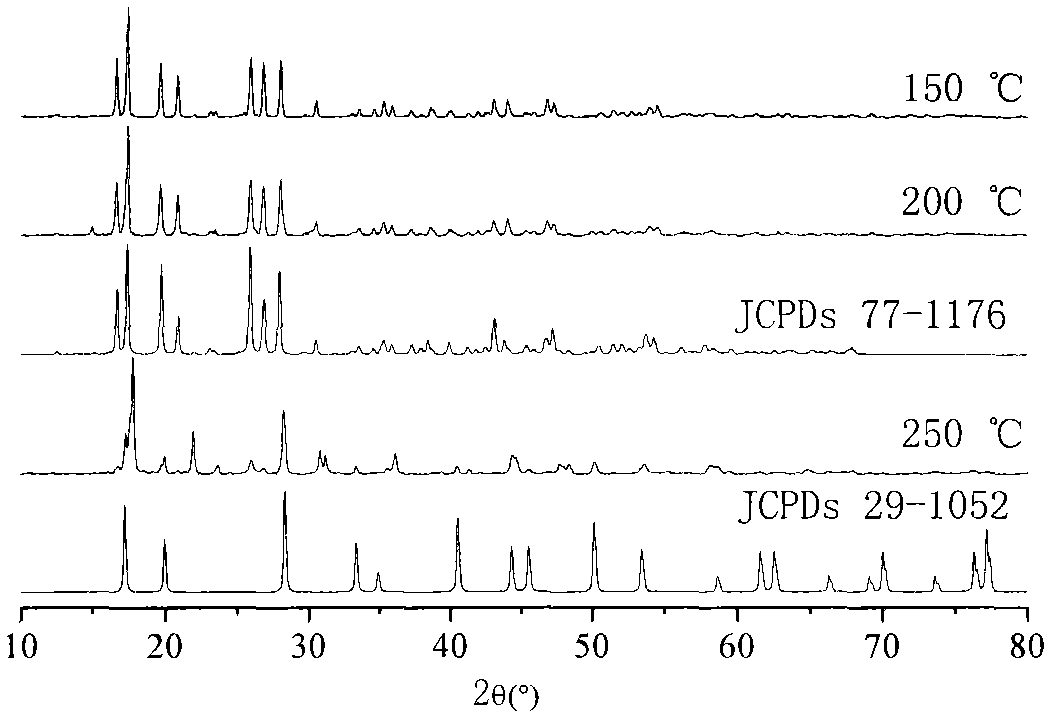

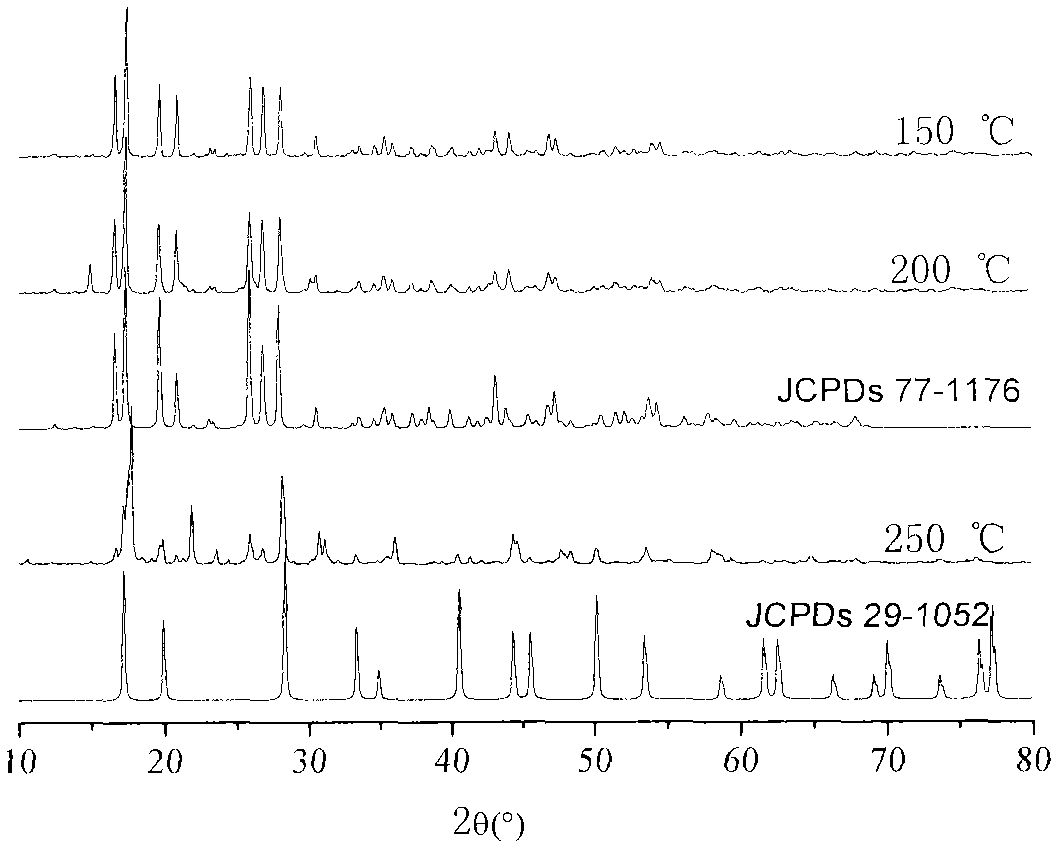

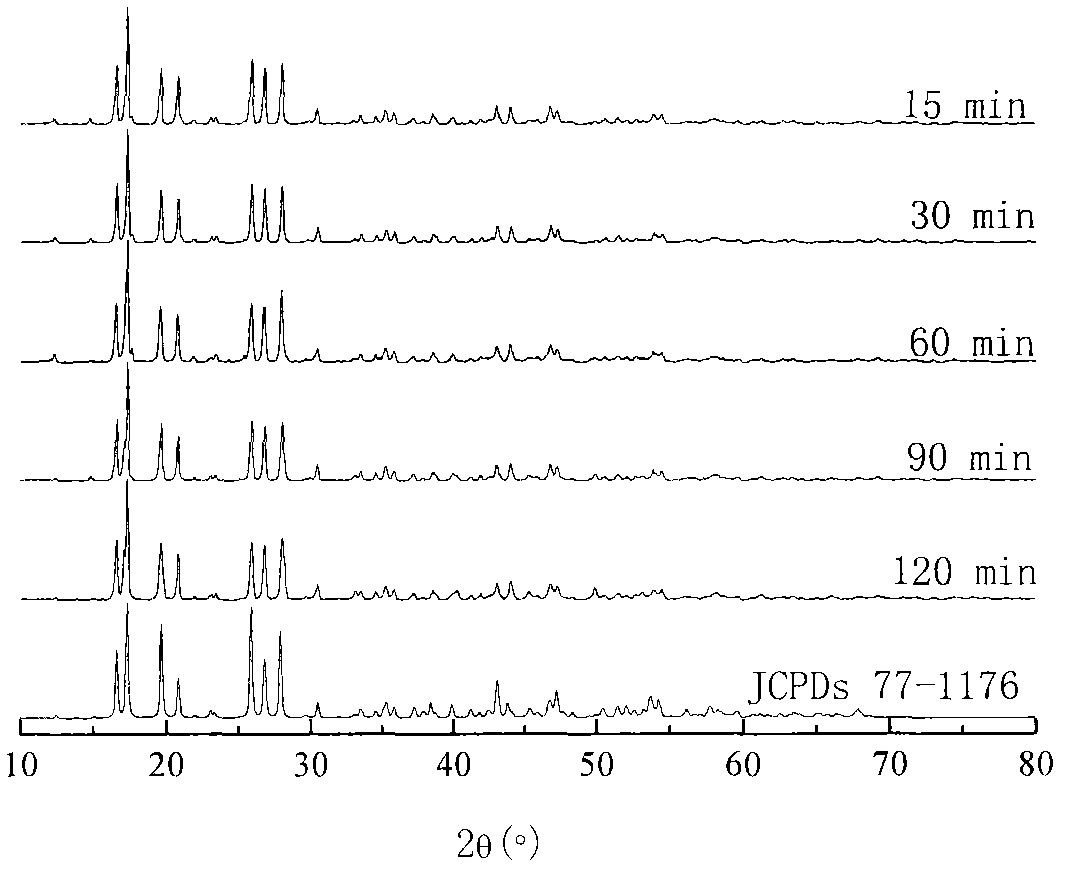

Thermal decomposition synthesis method of potassium fluotantalate

InactiveCN102583539ASimple and fast operationLow costTantalum halidesPotassium fluorideSynthesis methods

The invention relates to a thermal decomposition preparation method of potassium fluotantalate. The method is simple and convenient in operation, low in cost and high in direct yield, all volatile components volatilize, and the problem of carbon impurities is solved. Hydrogen tantalum oxide or tantalum pentoxide, potassium fluoride and ammonium bifluoride serve as raw materials, small amount of carbinol, ethanol or water serves as solvent, and a precursor is obtained through full grinding and drying. The prepared precursor is roasted at the temperatures of 150 DEG C, 200 DEG C and 250 DEG C for 3 hours, wherein the precursor is roasted at the temperature of 200 DEG C for respectively 15 minutes, 30 minutes, 60 minutes, 90 minutes and 120 minutes. Influences of the roasting temperature and the roasting time on synthesis of the potassium fluotantalate are investigated. The research shows that K2TaF7 crystals can be obtained by roasting the precursor at the temperature of 200 DEG C for 15 minutes, and the K2TaF7 crystals have high relative crystallinity and small particle sizes.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for recovering tantalum resources from potassium fluorotantalate crystallization mother liquor

ActiveCN111690827ASolve processing problemsSimple methodProcess efficiency improvementAmmoniacal nitrogenProcess engineering

The invention provides a method for recovering tantalum resources from potassium fluorotantalate crystallization mother liquor. The potassium fluorotantalate crystallization mother liquor is used as araw material. The method comprises the steps of acidification treatment on the potassium fluorotantalate crystallization mother liquor, extraction after adding of an extracting agent, separating, recovering and preparation of the tantalum resources, so that the problems that the treatment cost is high and treatment of produced ammonia-nitrogen wastewater is difficult due to the fact that tantalumresources is neutralized and recovered by ammonia in the prior art method in the tantalum-niobium wet smelting industry are solved. The method has the characteristics of simpleness, effectiveness, energy saving, emission reduction, environmental protection, small pollution, obvious economic benefits and the like.

Owner:江西拓泓新材料有限公司

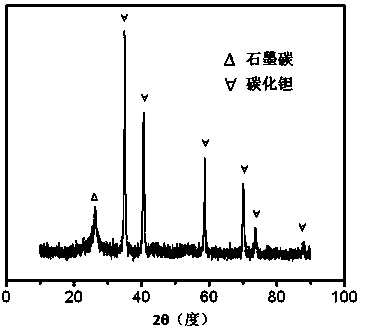

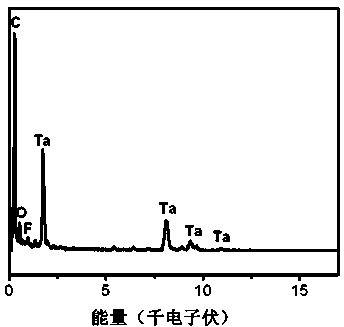

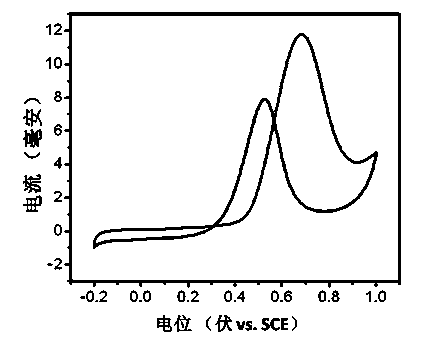

Fluorine-doped nano-tantalum carbide/graphitized carbon composite material and preparation method thereof

InactiveCN103977827ARich sourcesLow priceMaterial nanotechnologyPhysical/chemical process catalystsCarbon compositesPtru catalyst

The invention discloses a fluorine-doped nano-tantalum carbide / graphitized carbon composite material and a preparation method thereof. The preparation method comprises the steps of carrying out ion exchange resin pretreatment and transition metal salt ion exchange, adding potassium fluotantalate into water, stirring, carrying out thermal treatment in the presence of inert gas, and carrying out grinding and acid treatment on obtained materials, so as to obtain the composite material. The preparation method has the advantages that the raw materials are rich in sources and low in costs, and the doped nano-tantalum carbide / graphitized carbon composite material is synthesized at a relatively low temperature, so that the preparation cost is low, the process is simple and convenient, the preparation is rapid, safe and environmental friendly, and the large-scale production is easy to implement; furthermore, the composite material has a utilization potentiality in an anode catalyst of a fuel cell as well as certain active effects for relieving energy crisis, improving air pollution and generalize new energy electric vehicles.

Owner:SUN YAT SEN UNIV

Ta metallurgical by-product composite salt recycling method

The invention discloses a Ta metallurgical by-product composite salt recycling method. The method comprises the following steps: (1) after separating by-product composite salt produced during the Ta metallurgical process from Ta powder, the composite salt is rinsed with deionized water to remove the residue Na, and then the rinsed composite salt is crushed by a crusher and dried to obtain the treated composite salt; and (2) the treated composite salt is used as diluent, and is mixed with potassium fluotantalate based on certain proportion according to the process requirements and the mixture is taken to a furnace, and the Na is inlet for metallurgy process restoration to obtain the Ta powder. The by-product composite salt produced during the Ta metallurgical production process is used to produce the metallurgical-level Ta powder as the diluent, so that the recycling of the by-product composite salt is realized, the environmental problem caused by the by-product composite salt is avoided, and at the same time, cost is greatly saved. The method also has the advantages that the reuse of waste resources is realized, environmental pollution is reduced, direct yield of the Ta powder is effectively improved, and the Ta powder prepared according the recycling method meets the industry standard of metallurgical Ta powder.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method of production of tantalum powder with low impurity level

The production of tantalum powder having a low impurity level is provided by a method in which potassium heptafluotantalate is added to a mixture of alkali metal halides in reactor vessel in which the internal surface and auxiliary input accessories of the reactor are covered with a tantalum coating. In one embodiment, the production of tantalum powder with low impurity level includes depositing a protective tantalum coating onto an internal surface of the reactor vessel and auxiliary accessories of a reactor by electrolysis of a mixture of alkali metals halides and potassium heptafluotantalate.

Owner:KEMET BLUE POWDER CORP

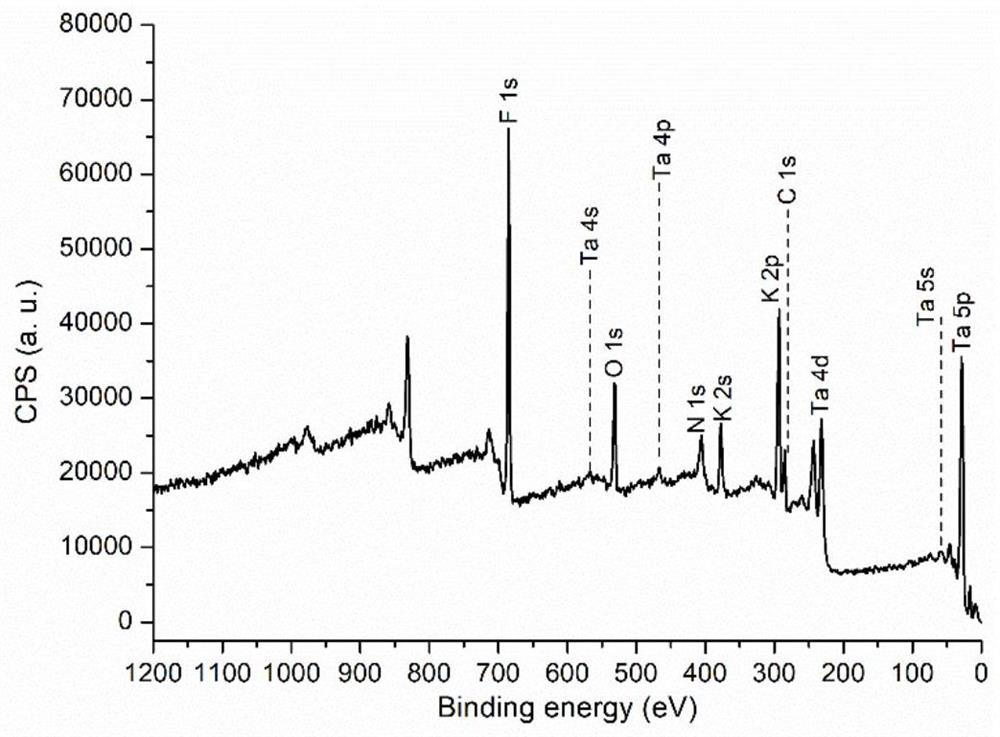

Method for electrochemical deep removal of water-soluble extractant in tantalum liquid in potassium fluotantalate preparation process

The invention discloses a method for electrochemical deep removal of a water-soluble extractant in a tantalum liquid in the potassium fluotantalate preparation process, and belongs to the technical field of deep removal of the water-soluble organic extractant in wet metallurgy extraction separation and purification processes. The method comprises the following steps: putting the tantalum liquid extracted and separated in the potassium fluotantalate production process flow into a reaction container; taking a tantalum rod as an anode and a tantalum material as an anode, immersing the cathode andthe anode into the tantalum liquid, applying an electric field of 1.5-3 V to the cathode and the anode, performing constant-potential electrolysis until the concentration of the water-soluble extractant dissolved in an aqueous tantalum solution is not changed, and continuously and uniformly introducing air from the bottom of a reaction container in the electrolysis process to achieve physical stripping; and carrying out a subsequent process for preparing potassium fluotantalate after the electrolysis is finished in order to obtain high-purity potassium fluotantalate. The method can effectively remove the water-soluble extractant dissolved in the solution deeply and prepares the low-carbon high-purity potassium fluotantalate. The method has the advantages of low energy consumption, and simplicity in operation.

Owner:NORTHEASTERN UNIV

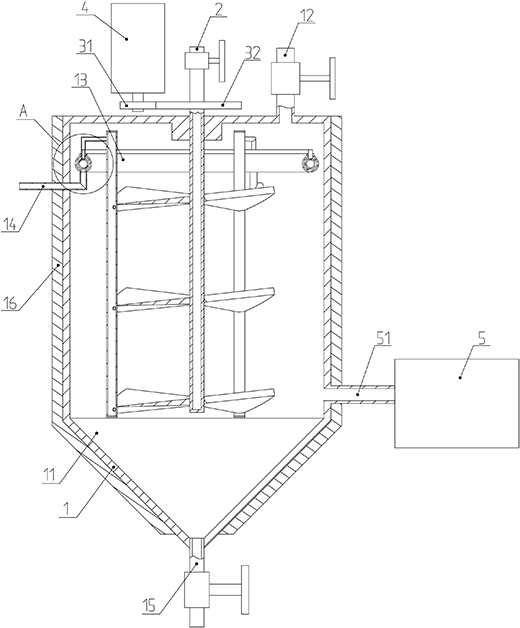

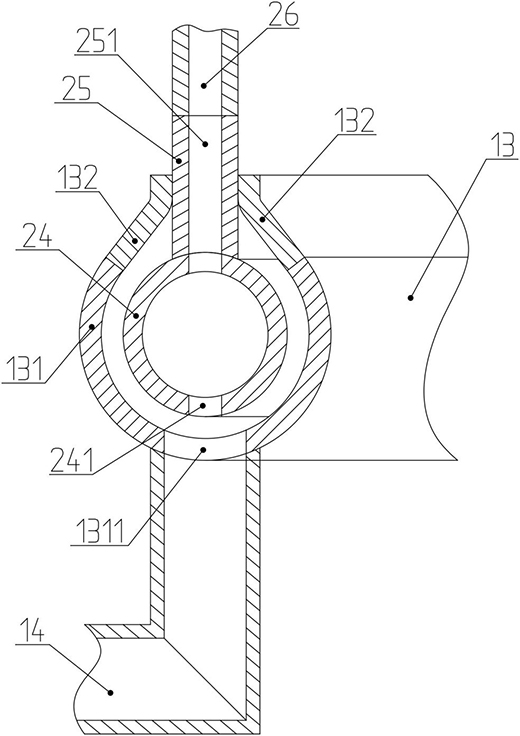

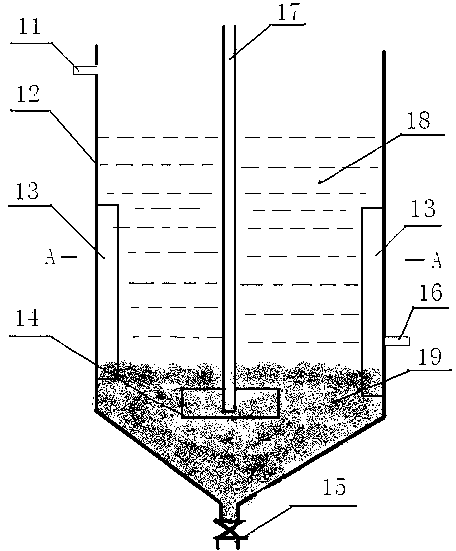

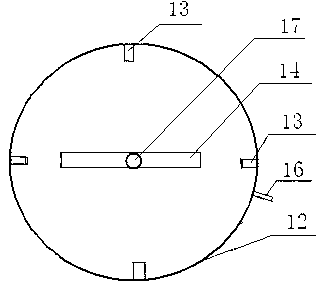

Dynamic crystallization equipment for potassium fluotantalate

PendingCN114669079AUniform temperatureUniform concentrationRotary stirring mixersTantalum compoundsChemical reactionPotassium

The invention belongs to the technical field of chemical reaction vessels, and relates to dynamic crystallization equipment for potassium fluotantalate. Cold water enters the circuitous hole through the cold medium inlet pipe, the cooling capacity of the cold water is transmitted to the stirring blades and the surrounding potassium fluotantalate solution, and the cold water is discharged from an outlet of the circuitous hole, then enters the connecting vertical pipe, flows upwards, enters the water return ring through the water return elbow and the water passing hole of the sealing ring, and flows into the water receiving ring through the water drainage hole of the water return ring. And the water is buffered and temporarily stored in the space between the water return ring and the water receiving ring, and then flows out of the tank body through the water receiving ring drain hole and the drain pipe. The laser particle analyzer detects the size of particles in the potassium fluotantalate solution in real time and sends information to the PLC, and the PLC controls the rotating speed of the stirring blade assembly through the motor according to the received information. The invention has the advantages of high heat exchange efficiency, uniform size of crystal grains separated by crystallization, good product quality, no serious crystal adhesion, automatic detection of granularity size, automatic adjustment of stirring speed, and small cleaning workload.

Owner:稀美资源(广东)有限公司

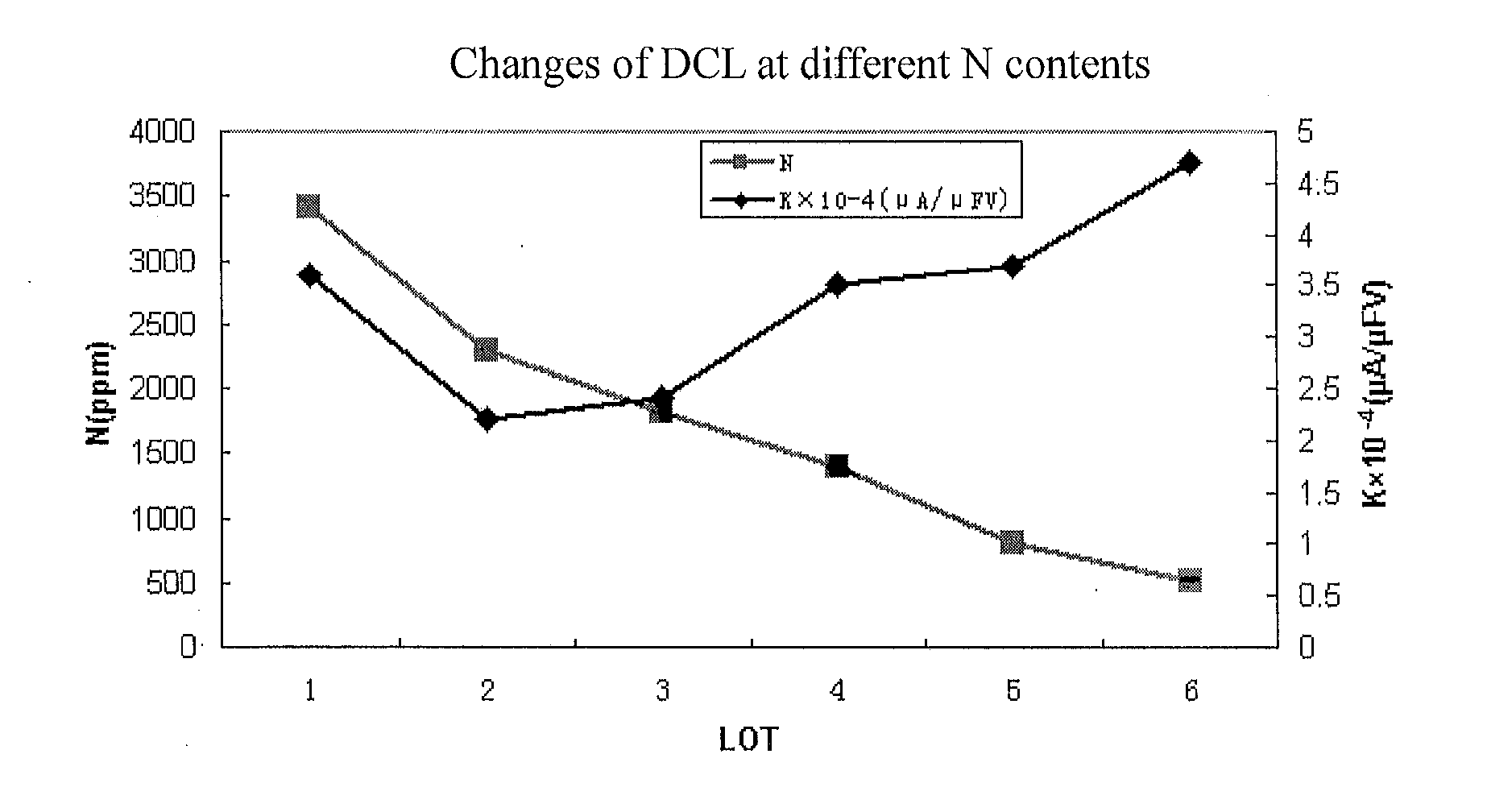

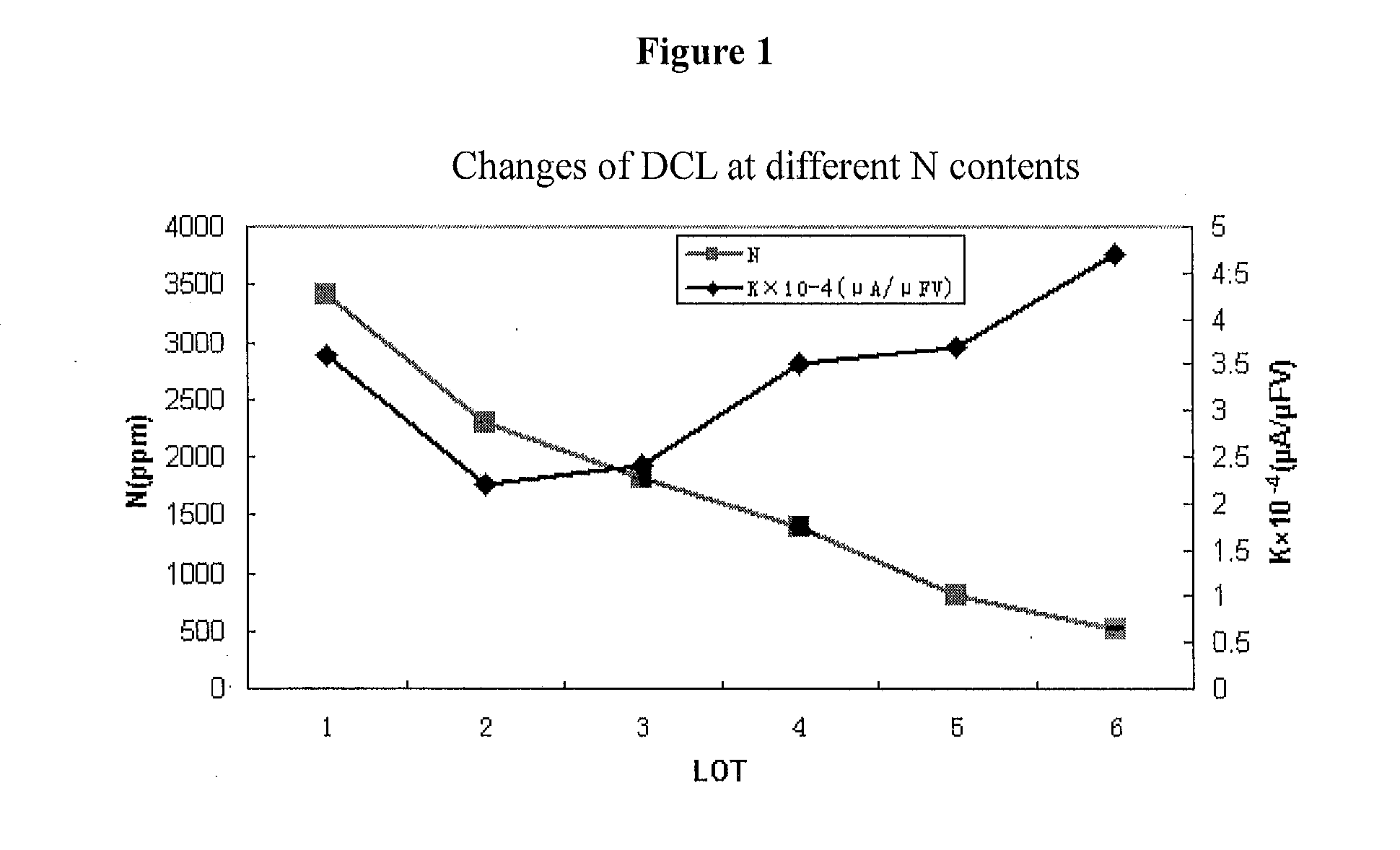

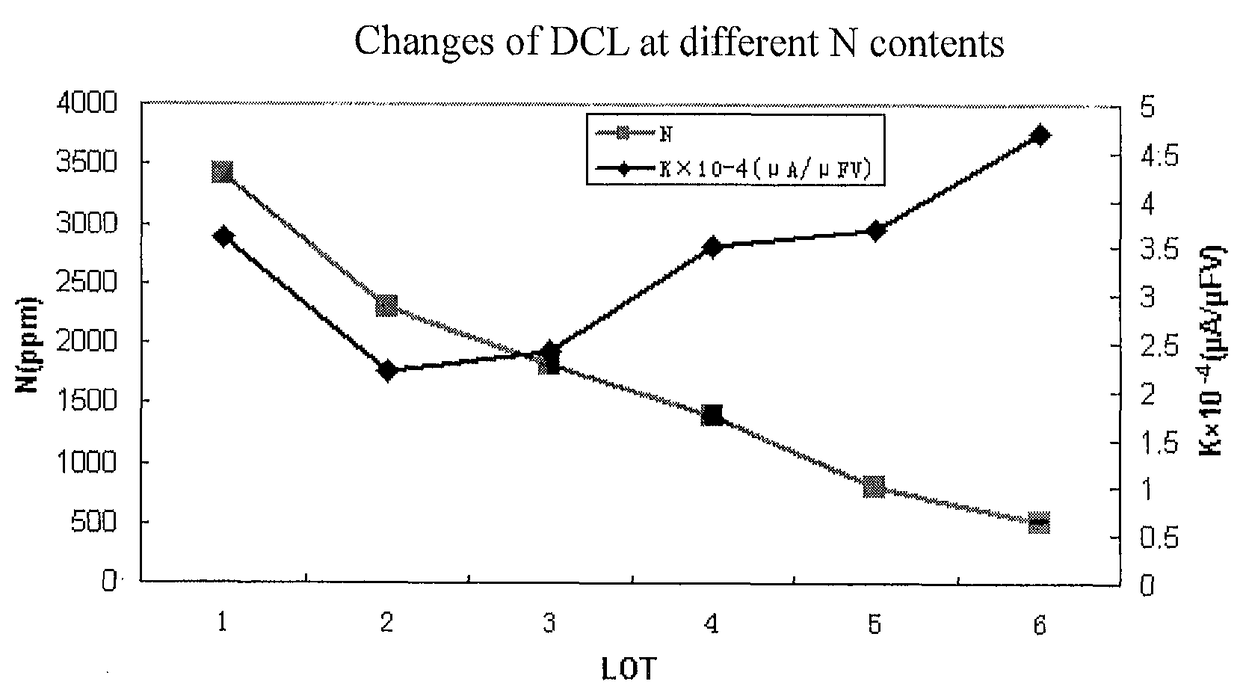

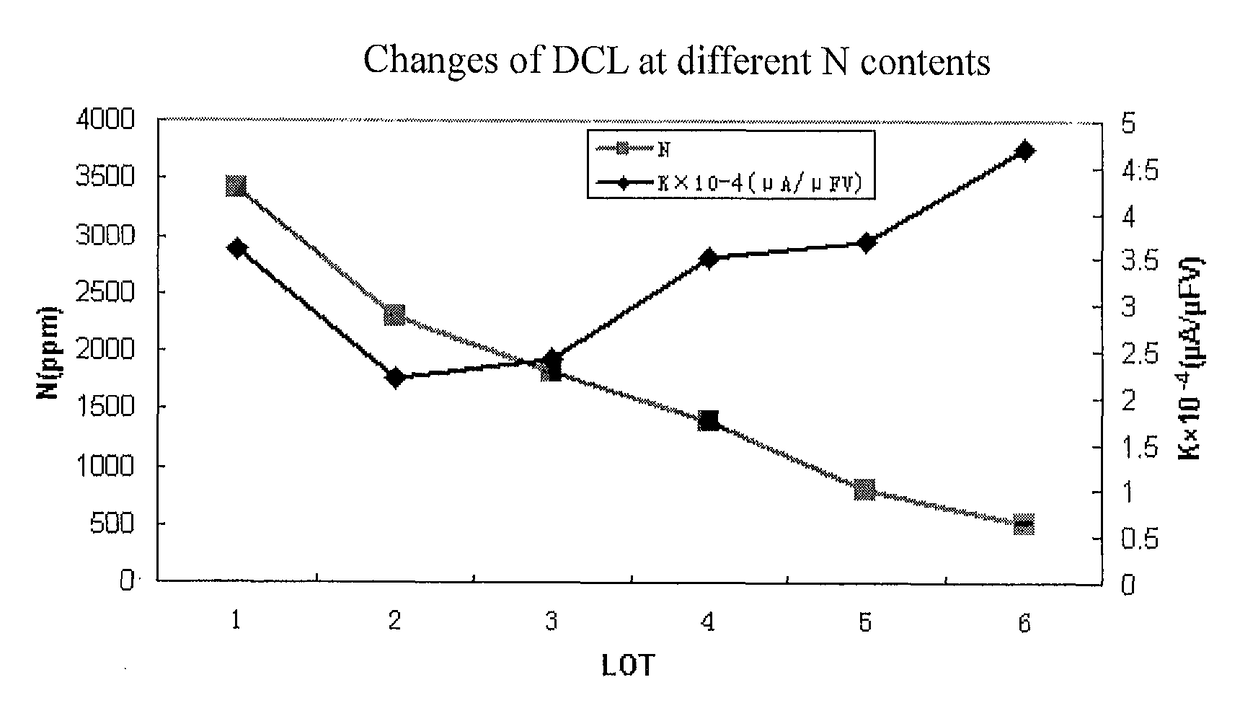

Method for preparing tantalum powder of capacitor grade with high nitrogen content, tantalum powder of capacitor grade prepared by the process, and an anode and a capacitor made of the tantalum powder

ActiveUS20160059319A1High nitrogen contentEasy to controlCell electrodesCapacitor electrolytes/absorbentsCapacitanceTantalum nitride

A method for preparing a tantalum power of capacitor grade, comprising: solid tantalum nitride is added when potassium fluotantalate is reduced by sodium. The method increases the nitrogen content in the tantalum powder, and at the same time improves the electrical performance of the tantalum powder. The specific capacitance is increased, and the leakage current and loss is improved. The qualification rate of the anode and the capacitor product is also improved. The method is characterized in that the nitrogen in the tantalum nitride diffuses between the particles of the tantalum powder, with substantially no loss, and thus the nitrogen content is accurate and controllable.

Owner:NINGXIA ORIENT TANTALUM IND +1

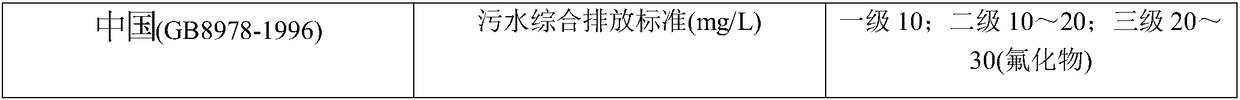

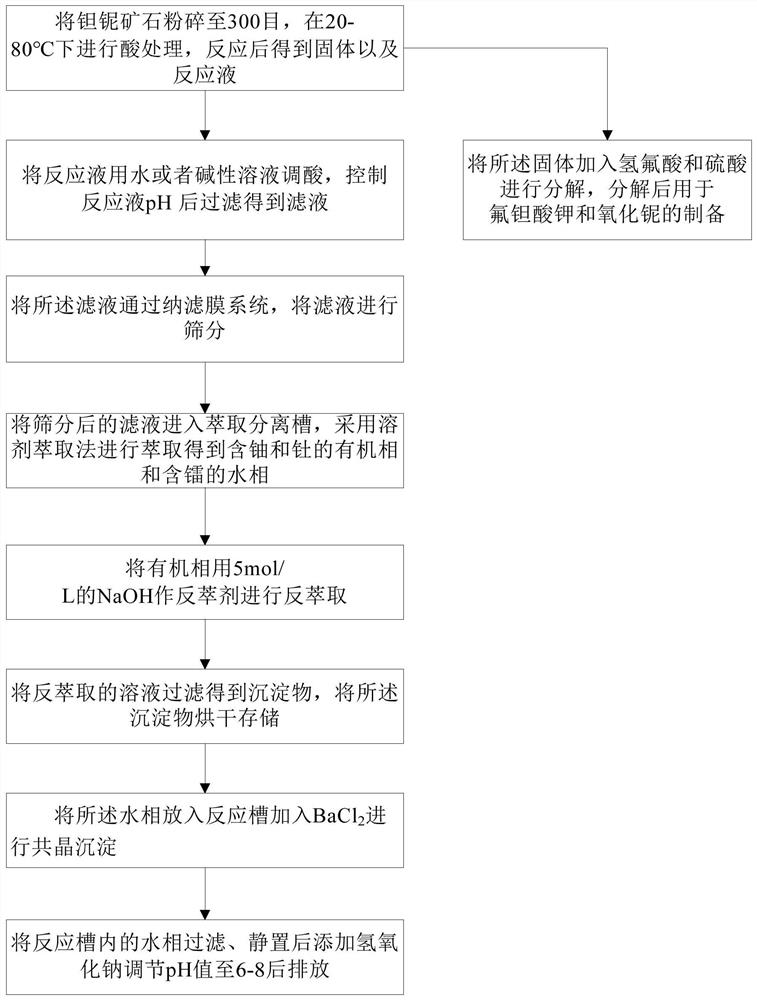

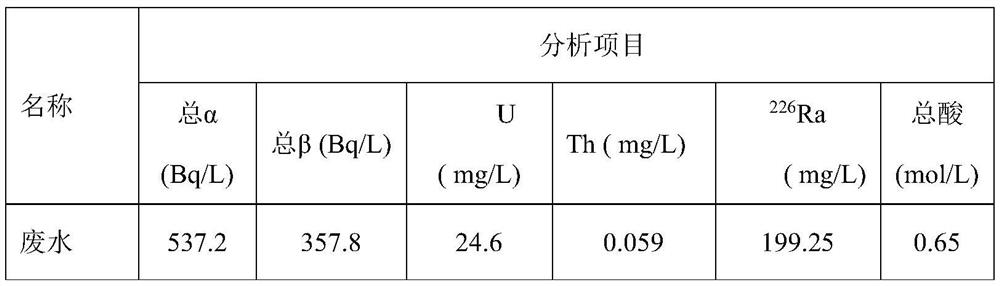

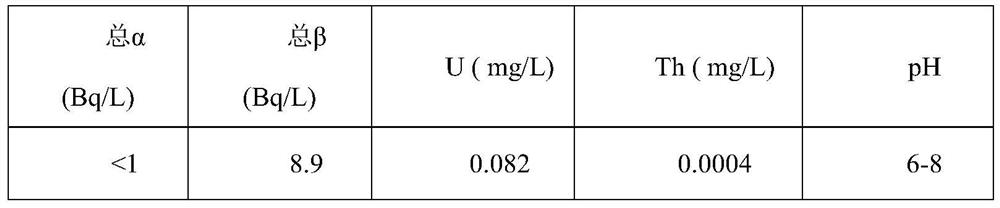

Treatment method for wastewater produced during tantalum-niobium hydrometallurgy

InactiveCN113149269AAvoid it happening againTo achieve the purpose of enriching uranium, thorium and radium elementsTreatment involving filtrationWaste water treatment from metallurgical processPhysical chemistryHydrometallurgy

The invention discloses a treatment method for wastewater produced during tantalum-niobium hydrometallurgy. The treatment method comprises the following steps: crushing tantalum-niobium ore to 300 meshes, carrying out acid treatment at 20-80 DEG C, and conducting reacting to obtain a solid and a reaction solution; adding hydrofluoric acid and sulfuric acid into the solid for decomposition, and then carrying out a preparation process for potassium fluotantalate and niobium oxide; adjusting the acid of the reaction solution with water or an alkaline solution to enable the pH value of the reaction solution to be 1-1.5, and conducting filtering to obtain a filtrate; enabling the filtrate to pass through a nanofiltration membrane system, and screening the filtrate; allowing the screened filtrate to enter an extraction separation tank, and conducting extraction by using a solvent extraction method to obtain an organic phase containing uranium and thorium and a water phase containing radium; carrying out back extraction on the organic phase by using NaOH with a concentration of 5 mol / L as a back extraction agent; filtering the back-extracted solution to obtain a precipitate, and drying and storing the precipitate; putting the water phase into a reaction tank, adding BaCl2, and carrying out eutectic precipitation; and filtering the water phase in the reaction tank, conducting standing, and adding sodium hydroxide to adjust the pH value to 6-8.

Owner:NINGXIA ORIENT TANTALUM IND

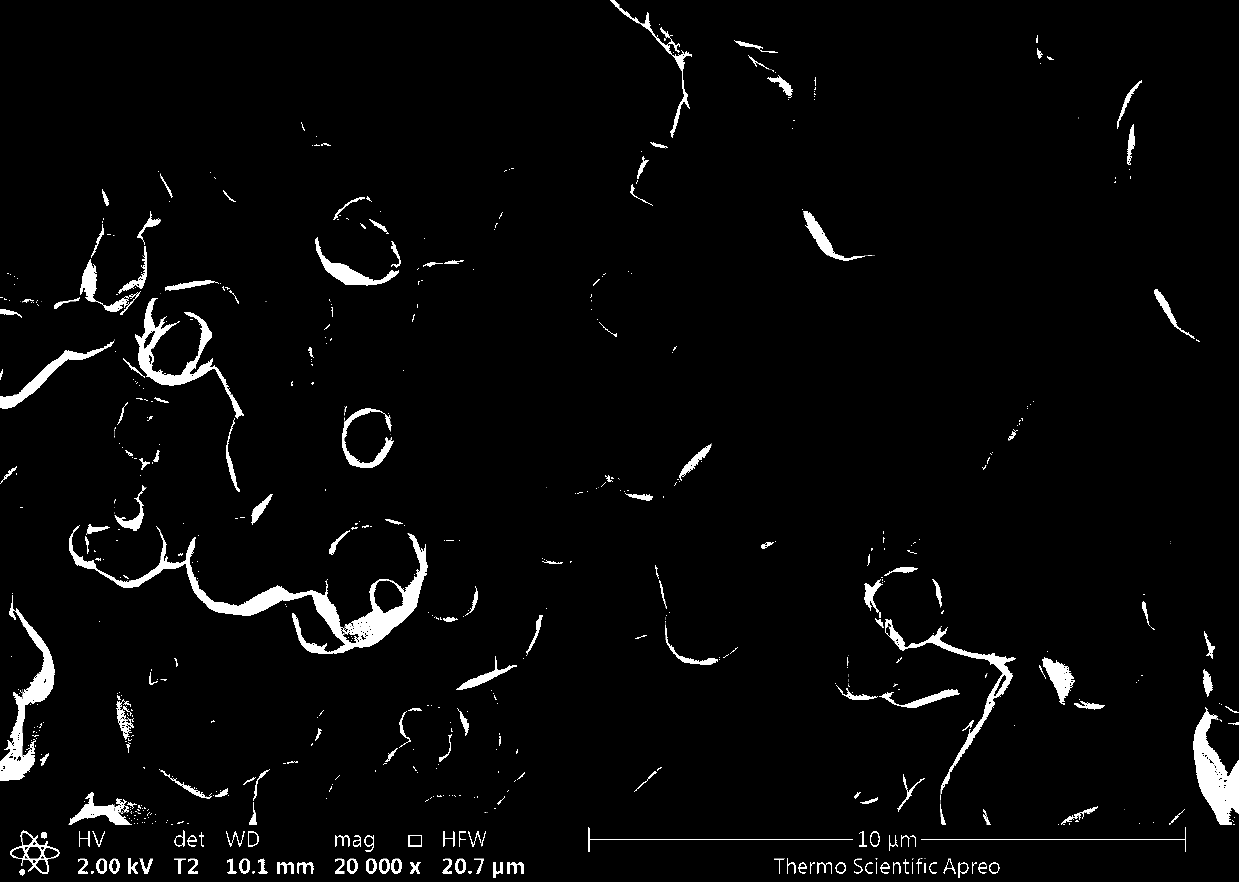

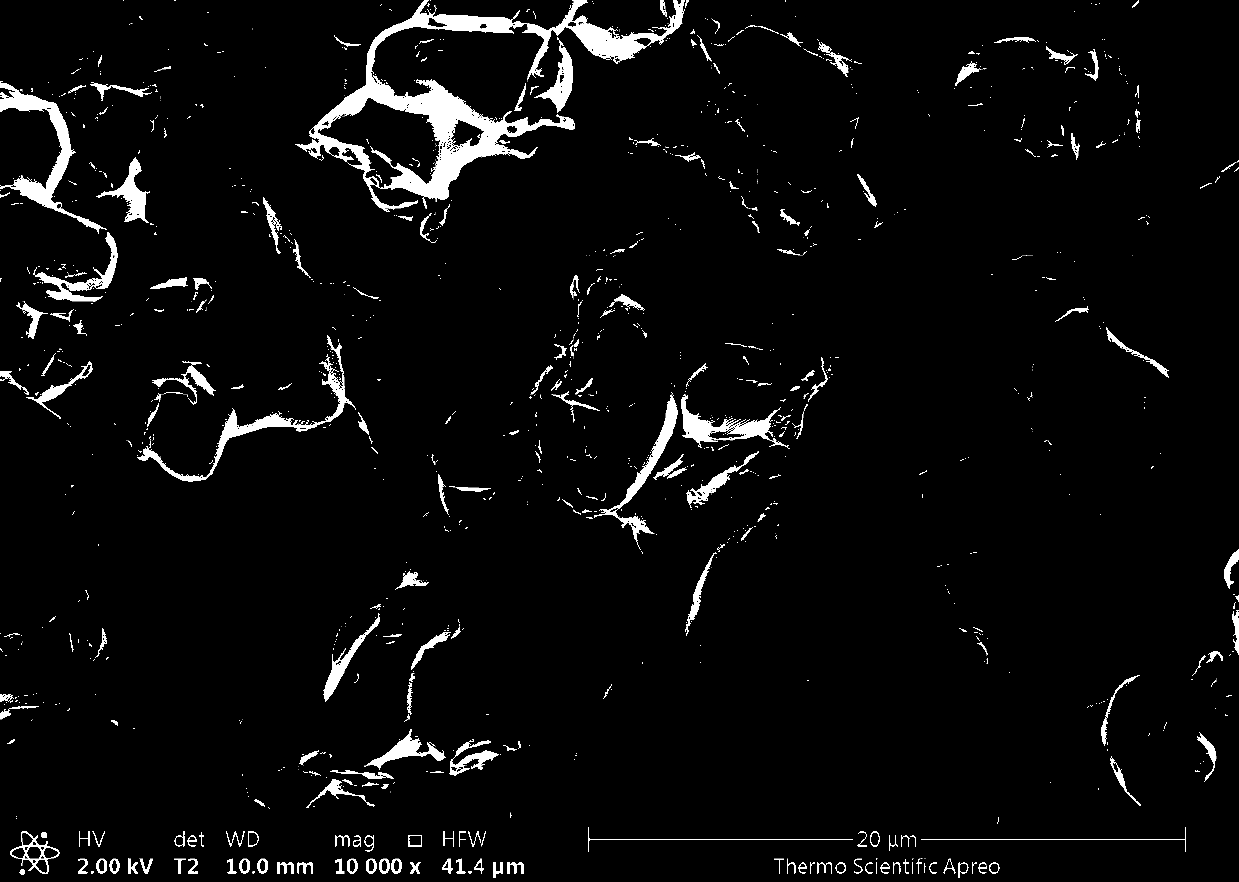

Preparation method of coralline high-purity tantalum powder

The invention provides a preparation method of coralline high-purity tantalum powder, and the mehtod comprises the following steps of (1) activating needle-shaped potassium fluotantalate into powder;(2) making NaCl free of water; (3) filtering and purifying the metal sodium to obtain purified sodium; (4) filling powdery potassium fluotantalate and NaCl into a reduction tank, hoisting the reduction tank into a well chamber reduction furnace, vacuumizing, filling argon for replacement, heating to 100 DEG C, inputting purified sodium, and continuously heating; (5) when the temperature increasesto 750 DEG C, carrying out sodium reduction; (6) after the sodium injection is finished, keeping constant temperature, lifting out the reduction tank, naturally cooling, taking out and crushing into amixture; (7) washing with water and acid to obtain washing powder; and (8) carrying out heat treatment on the washing powder, taking out of the furnace, sieving, and analyzing the qualified undersizeto obtain the coralline high-purity tantalum powder. By controlling the reaction process of preparing the tantalum powder by reducing potassium fluotantalate with the sodium metal, the preparation method of coralline high-purity tantalum powder can absorb metal impurities as little as possible and prevent the reaction product metal tantalum from being oxidized, and can directly prepare the coralliform high-purity tantalum powder with low metal impurity content and low oxygen content.

Owner:CONGHUA TANTALUM & NIOBIUM SMELTERY

Rinsing method of potassium fluotantalate product obtained through sodium reduction

The invention relates to a rinsing method and device of a potassium fluotantalate product obtained through sodium reduction. The rinsing method comprises the following steps: using sodium to reduce potassium fluotantalate and obtain coagulum, crushing the coagulum, diafiltrating, rinsing, stirring to rinse, pickling, and drying to obtain raw tantalum powder. The obtained tantalum powder has high purity and good porosity and can be used to prepare condensed tantalum powder which is particularly suitable for the manufacture of the electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

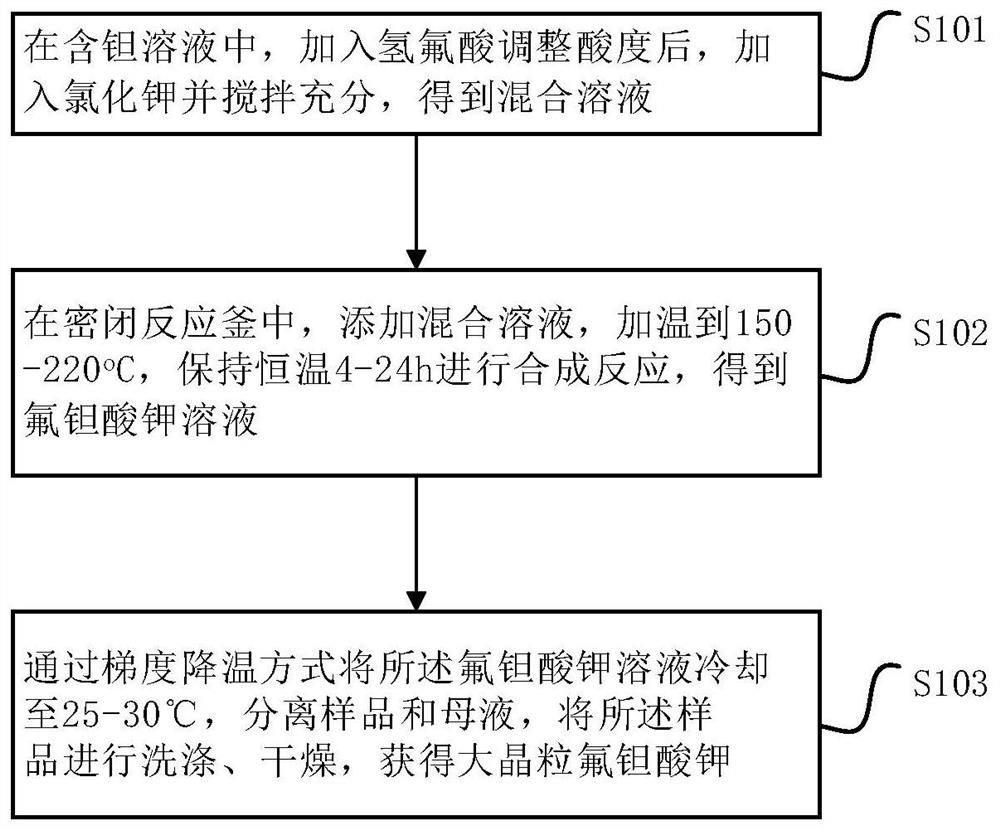

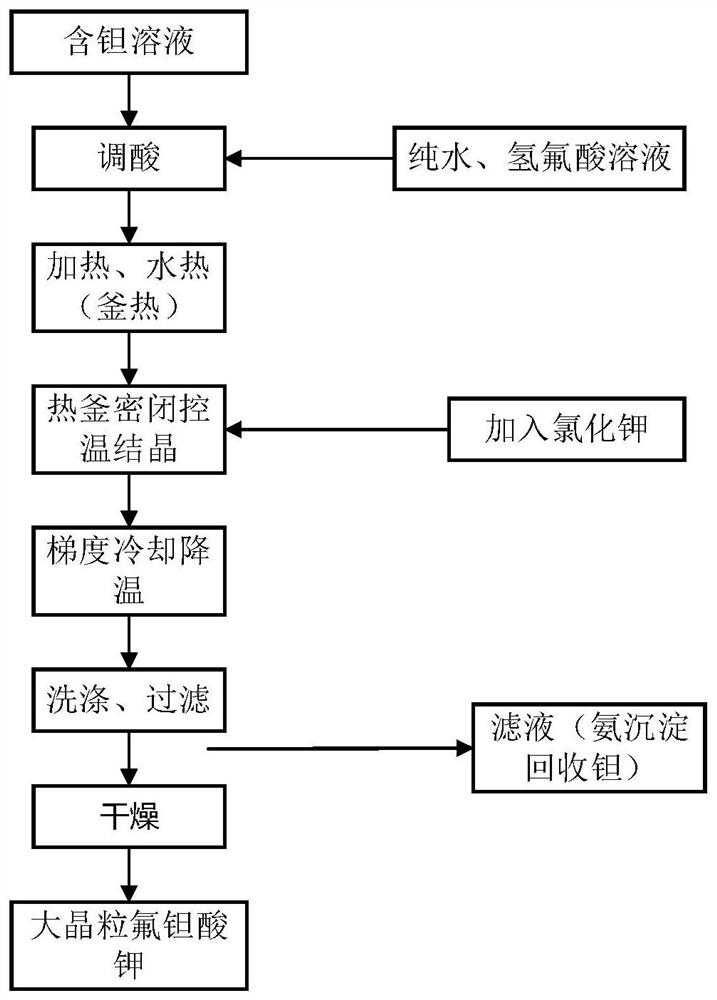

Method for preparing large-grain potassium fluotantalate by hydrothermal crystallization method

PendingCN113428900AFully crystallizedCrystal synthesis completeTantalum compoundsPhysical chemistryChloride potassium

The invention relates to the technical field of potassium fluotantalate preparation methods, in particular to a method for preparing large-grain potassium fluotantalate by a hydrothermal crystallization method. The problems that potassium fluotantalate prepared through an existing method is low in purity, small in crystal grain, long in crystallization time and the like are solved. The method comprises the steps of adding hydrofluoric acid into a tantalum-containing solution to adjust the acidity, adding potassium chloride, and fully stirring to obtain a mixed solution; adding the mixed solution into a closed reaction kettle, heating to the temperature of 150-220 DEG C, keeping the constant temperature for 4-24 hours, and carrying out a synthetic reaction to obtain a potassium fluotantalate solution; and cooling the potassium fluotantalate solution to 25-30 DEG C in a gradient cooling manner, separating a sample from a mother solution, and washing and drying the sample to obtain the large-grain potassium fluotantalate.

Owner:NINGXIA ORIENT TANTALUM IND

A method for reducing the amount of ammonia used in the hydrometallurgical process of tantalum and niobium

InactiveCN104480304BReduce acidityAcidity directly affects the reduction of the amount of ammonia usedProcess efficiency improvementFiltrationPotassium

The invention relates to a method for reducing usage amount of ammonia gas during the process of tantalum-niobium hydrometallurgical extraction. The method is as follows: 1, concentrated sulfuric acid is added into a niobium-containing acid solution to reduce acidity of the niobium-containing acid solution, and MIBK extraction, back-extraction, ammonia gas neutralization and the like are carried out to prepare a niobium oxide product; 2, as potassium fluotantalate is separated and extracted from a tantalum-containing acid solution by crystallization and filtration processes, a part of fluorotantalic acid is left in a mother liquor. In the prior art, ammonia gas must be utilized for neutralization and recovery. Thus, a lot of ammonia-containing wastewater is caused. According to the invention, part of alkaline matters (such as sodium hydroxide, magnesium hydrate, calcium hydroxide and the like) are used to replace ammonia gas and added into a mother liquor containing a fluorotantalic acid solution, and then ammonia gas is used for neutralization. Through the above two measures, the purpose of reducing consumption of ammonia gas and decreasing discharge of ammonia-containing wastewater is finally achieved.

Owner:NINGXIA ORIENT TANTALUM IND

Stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium

The invention relates to a stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium. The water-washing method comprises the following steps of: performing stirring water-washing on the tantalum powder obtained by reducing potassium fluotantalate (K2TaF7) via metallic sodium (Na) which removes alkali metal haloids in an electrolyte solution, so as to remove harmful and indissolvable ultrafine-particle impurities in the tantalum powder; and then performing acid-washing and drying to obtain the initial tantalum powder. The method is high in the yield of tantalum powder; and the obtained tantalum powder is high in purity, good in particle size distribution and porosity, and especially suitable for manufacturing a tantalum electrolytic capacitor.

Owner:NINGXIA ORIENT TANTALUM IND

Method for recovering tantalum resources from potassium fluorotantalate crystallization mother liquor

ActiveCN111690827BSolve processing problemsSimple methodProcess efficiency improvementAmmoniacal nitrogenPotassium

Owner:江西拓泓新材料有限公司

Method for preparing tantalum powder of capacitor grade with high nitrogen content, tantalum powder of capacitor grade prepared thereby, and anode and capacitor prepared from tantalum powder

ActiveUS9764388B2High nitrogen contentEasy to controlCapacitor electrolytes/absorbentsCapacitanceTantalum nitride

A method for preparing a tantalum power of capacitor grade, comprising: solid tantalum nitride is added when potassium fluotantalate is reduced by sodium. The method increases the nitrogen content in the tantalum powder, and at the same time improves the electrical performance of the tantalum powder. The specific capacitance is increased, and the leakage current and loss is improved. The qualification rate of the anode and the capacitor product is also improved. The method is characterized in that the nitrogen in the tantalum nitride diffuses between the particles of the tantalum powder, with substantially no loss, and thus the nitrogen content is accurate and controllable.

Owner:NINGXIA ORIENT TANTALUM IND +1

Preparation method of high-purity potassium fluorotantalate

The invention relates to a preparation method of high-purity potassium fluorotantalate. The preparation method is characterized by comprising the following steps: (1) decomposition: adding tantalum-niobium mineral into hydrofluoric acid and sulfuric acid for decomposition; (2) mineral-pulp extraction: utilizing an MIBK (Methyl Isobutyl Ketone) solvent or sec-octyl alcohol solvent to carry out backflow extraction and extracting fluorine-niobium acid and fluorine-tantalum acid into the solvent; (3) acid pickling: adopting sulfuric-acid solution to be contacted with the solvent obtained after extraction of step (2) in a backflow manner; (4) tantalum extraction by back extraction of niobium: utilizing the sulfuric-acid solution and the obtained solvent to carry out backflow extraction in an extraction groove, extracting the fluorine-niobium acid into an aqueous phase and forming fluorine-niobium acid aqueous solution; (5) back extraction of tantalum: placing the remaining organic solutionin another extraction groove, utilizing pure water to carry out back extraction on fluorine-tantalum acid organic solution into the pure water and forming fluorine-tantalum acid aqueous solution; (6)synthesis; (7) cooling and crystallization. The method for preparing high-purity potassium fluorotantalate by a method of sectional back extraction and sectional crystallization has the beneficial effect that impurities in the potassium fluorotantalate can be effectively removed.

Owner:NINGXIA ORIENT TANTALUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com