Thermal decomposition synthesis method of potassium fluotantalate

A technology of potassium fluorotantalate and potassium fluoride is applied in the field of preparation of potassium fluorotantalate, which can solve the problems of complicated operation process and high equipment requirements, and achieve the effects of low carbon content, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

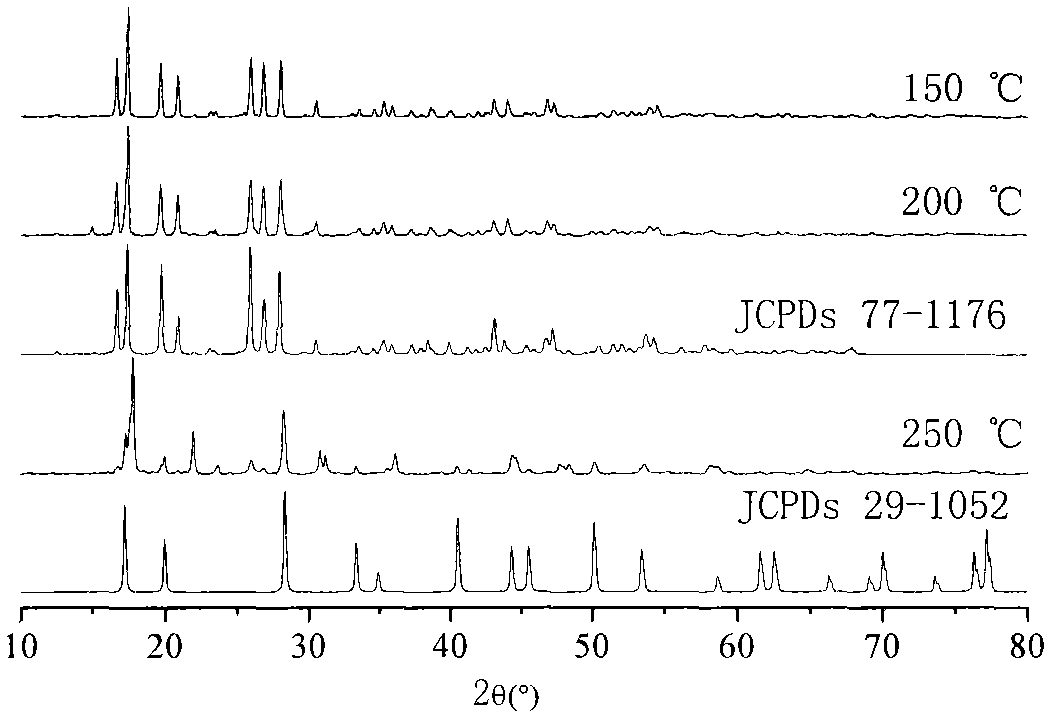

[0024] Accurately weigh 7.2658g potassium fluoride (KF 2.12H 2 O, Sinopharm Chemical Reagent Co., Ltd., 99.0%), 10.7164g ammonium bifluoride (Sinopharm Chemical Reagent Co., Ltd., 98.0%) and 10.7609g tantalum hydroxide (Jiujiang Jinxin Nonferrous Metals Co., Ltd., 99.99%), w(Ta 2 o 5)=77.15%), put the three in a polytetrafluoroethylene mortar and grind them thoroughly, add 6mL of 99.5% methanol to make the mixture into a paste, in order to achieve full mixing, after grinding for 4-5 hours under the infrared lamp Evaporation of methanol and water yielded a homogeneously dispersed potassium fluorotantalate precursor. The precursor was calcined at 150°C, 200°C and 250°C for 180min. attached by figure 1 It can be seen that at 150 ° C, a single-phase potassium fluorotantalate crystal is obtained, but the K obtained at this temperature 2 TaF 7 The degree of crystallinity is not high. The K obtained when the calcination temperature is 200°C 2 TaF 7 , its XRD peak is strong an...

Embodiment 2

[0025] Embodiment 2 (comparative example):

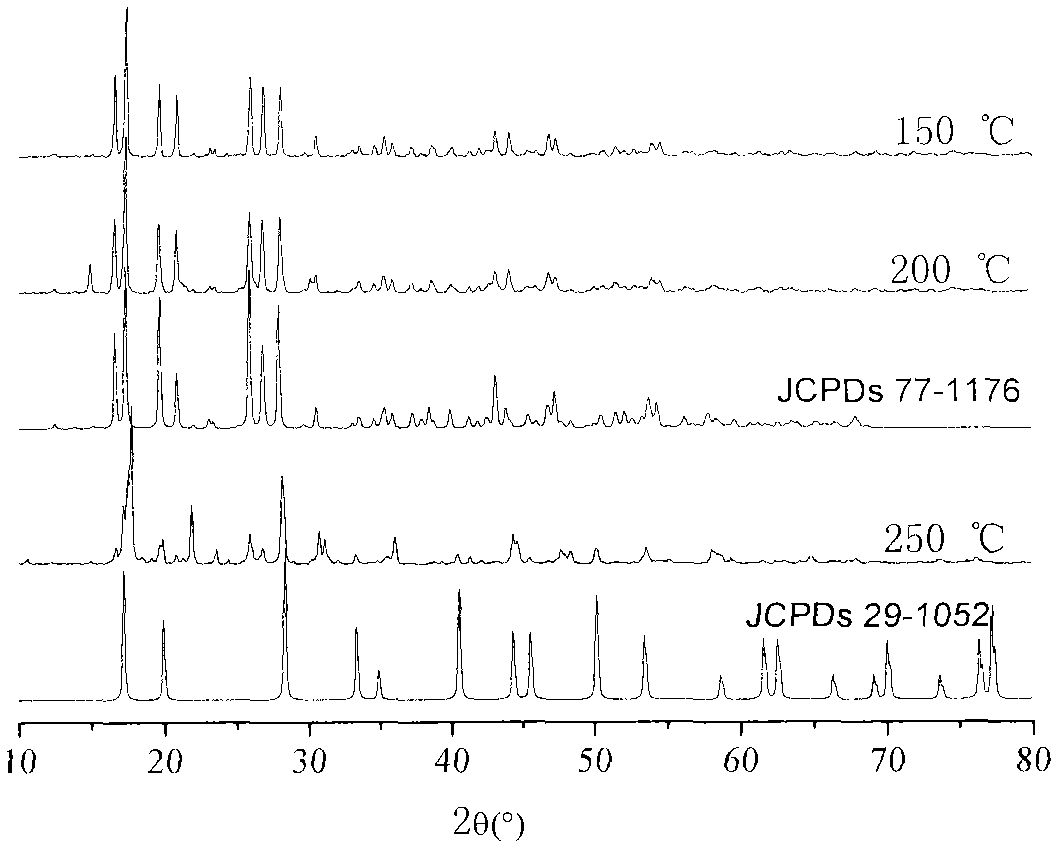

[0026] Accurately weigh 7.5316g potassium fluoride (KF 2.12H 2 (2), 11.1084g ammonium bifluoride and 8.6057g tantalum pentoxide (Jiujiang Jinxin Nonferrous Metals Co., Ltd., 99.99%), the three are placed in a polytetrafluoroethylene mortar and fully ground, and then 4mL99.5% methanol will The mixture is made into a paste to achieve thorough mixing, and after grinding for 4-5 hours under an infrared lamp, methanol and water are evaporated to obtain a homogeneously dispersed precursor of potassium fluorotantalate. The precursor was calcined at 150°C, 200°C and 250°C for 180min. attached by figure 2 It can be seen that the single-phase K 2 TaF 7 , the K 2 TaF 7 , the product contains K 3 TaOF 6 . The trace amount of carbon in the sample was measured with a coulometric carbon meter, and the measured carbon content was 5 ppm.

Embodiment 3

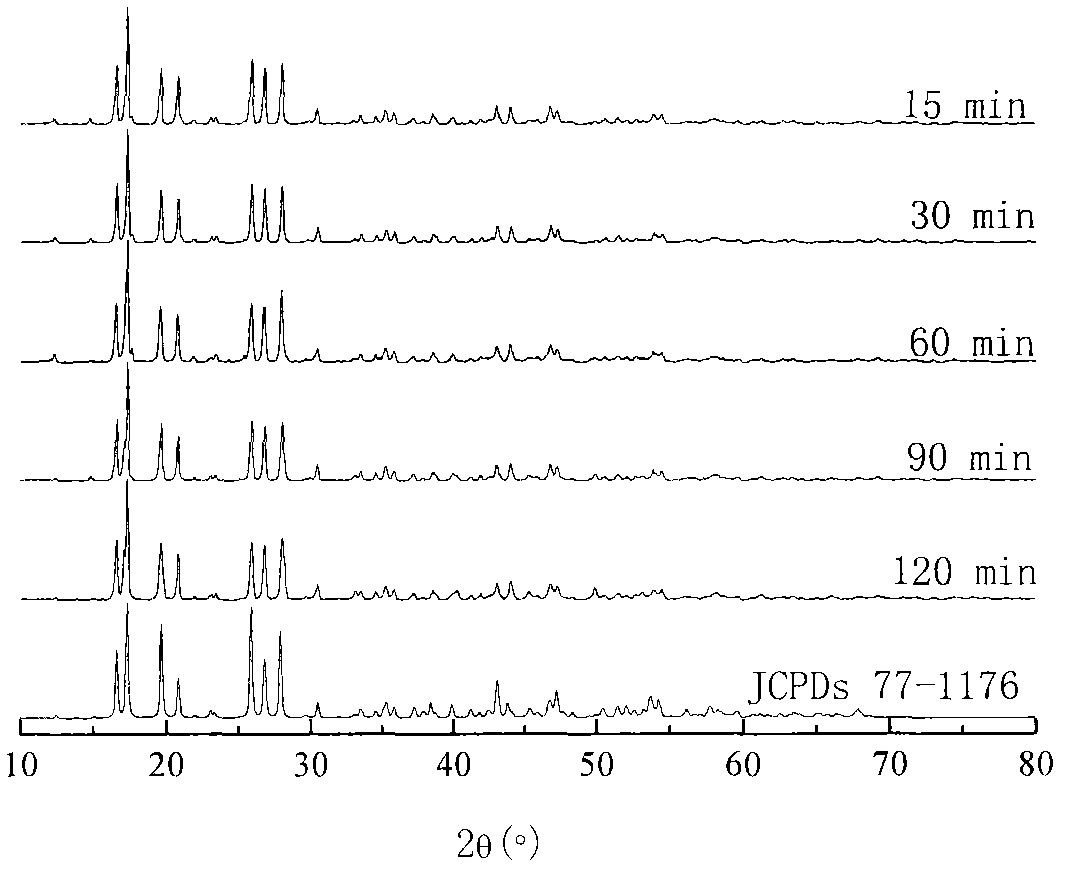

[0028] Accurately weigh 7.2658g potassium fluoride (KF 2.12H 2 O, Sinopharm Chemical Reagent Co., Ltd., 99.0%, AR), 10.7164g ammonium bifluoride and 10.7609g tantalum hydroxide, the three are fully ground in a polytetrafluoroethylene mortar, and then 6mL99.5% methanol is added to the mixture Make into a paste to achieve thorough mixing, grind for 4-5 hours under an infrared lamp, evaporate methanol and water to obtain a uniformly dispersed precursor of potassium fluorotantalate. The precursor was calcined at 200°C for 15min, 30min, 60min, 90min and 120min, respectively. attached by image 3 It can be seen that the single-phase K 2 TaF 7 . The trace amount of carbon in the sample was measured with a coulometric carbon meter, and the measured carbon content was 6ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com