Preparation method of phosphorus-containing tantalum powder

A technology of tantalum powder and phosphoric acid, which is applied in chemical instruments and methods, tantalum compounds, inorganic chemistry, etc., can solve the problem of uneven phosphorus doping, and achieve the effect of large specific surface area and high specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

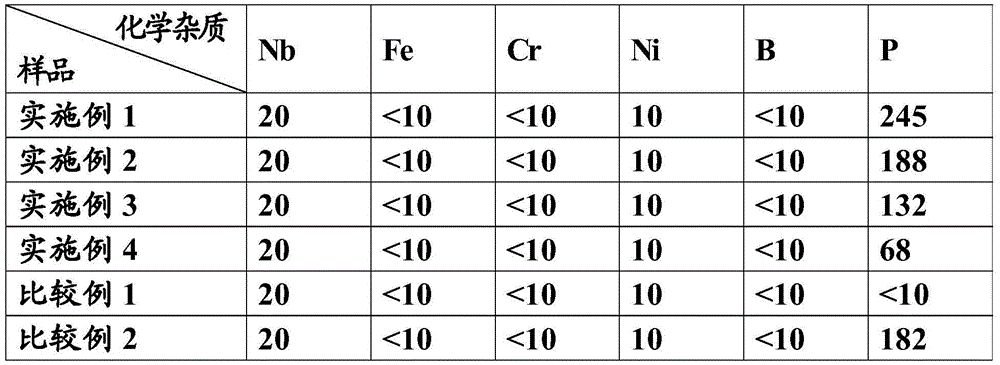

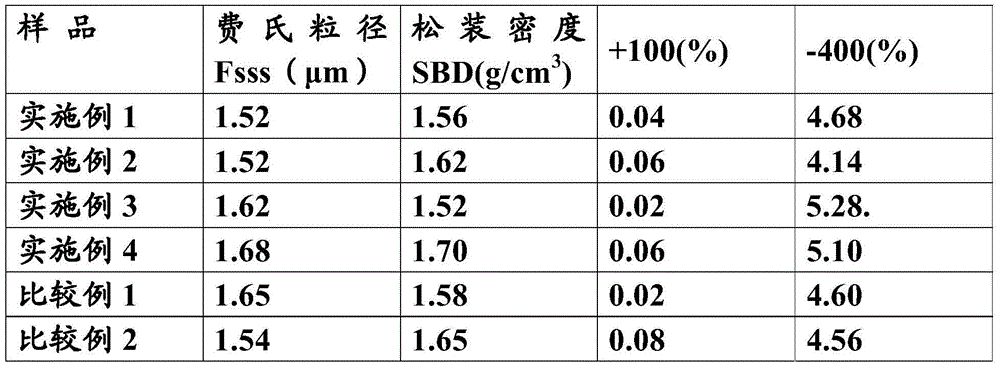

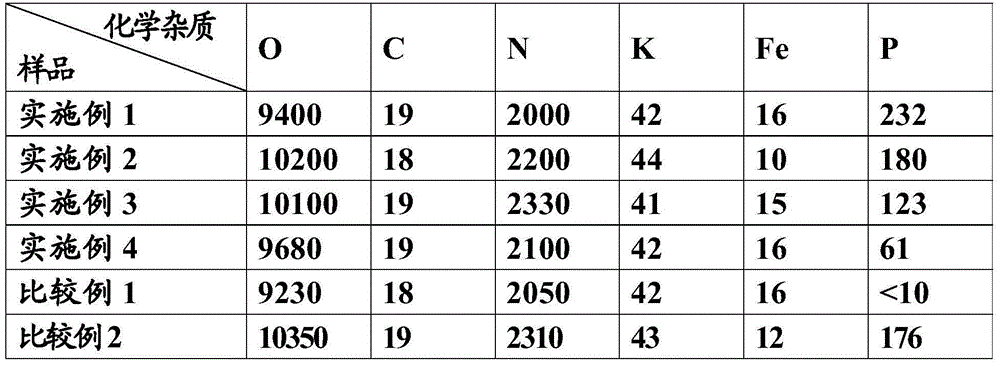

Examples

Embodiment 1

[0050] Firstly, during the production process of potassium fluorotantalate, the tantalum solution flowing out after extraction was sampled and analyzed. After testing, the concentration of the tantalum solution was 50g / l and the acidity was 0.9mol / l. Then put the tantalum liquid into the blow-off tank, and blow off with compressed air. The purpose of blow-off is to float part of the organic gas phase dissolved in the tantalum liquid to the upper layer of the solution in the blow-off tank, which can effectively reduce the final Carbon content in potassium fluorotantalate, stripping time 6h. Pour 1000L of the stripped tantalum liquid into the synthesis tank for synthesis, where the effective volume of the synthesis tank is 1300L. Add potassium chloride according to formula (1).

[0051] Add potassium chloride 40Kg in this embodiment. Then open the stirring paddle, add 53 liters of HF, the concentration of HF in the reaction solution after adding HF is about 1.3mol / l, add H 3 ...

Embodiment 2

[0054] Firstly, during the production process of potassium fluorotantalate, the tantalum solution flowing out after extraction was sampled and analyzed. After testing, the concentration of the tantalum solution was 50g / l and the acidity was 0.9mol / l. Then put the tantalum liquid into the blow-off tank, and blow off with compressed air. The purpose of blow-off is to float part of the organic gas phase dissolved in the tantalum liquid to the upper layer of the solution in the blow-off tank, which can effectively reduce the final Carbon content in potassium fluorotantalate, stripping time 6h. Pour 1000L of the stripped tantalum liquid into the synthesis tank for synthesis, where the effective volume of the synthesis tank is 1300L. Add potassium chloride according to formula (1).

[0055] Add potassium chloride 40Kg in this embodiment. Then open the stirring paddle, add 53 liters of HF, the concentration of HF in the reaction solution after adding HF is about 1.3mol / l, add H 3 ...

Embodiment 3

[0058] Firstly, during the production process of potassium fluorotantalate, the tantalum solution flowing out after extraction was sampled and analyzed. After testing, the concentration of the tantalum solution was 50g / l and the acidity was 0.9mol / l. Then put the tantalum liquid into the blow-off tank, and blow off with compressed air. The purpose of blow-off is to float part of the organic gas phase dissolved in the tantalum liquid to the upper layer of the solution in the blow-off tank, which can effectively reduce the final Carbon content in potassium fluorotantalate, stripping time 6h. Pour 1000L of the stripped tantalum liquid into the synthesis tank for synthesis, where the effective volume of the synthesis tank is 1300L. Add potassium chloride according to formula (1).

[0059] Add potassium chloride 40Kg in this embodiment. Then open the stirring paddle, add 53 liters of HF, the concentration of HF in the reaction solution after adding HF is about 1.3mol / l, add H 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com