Preparation method of high-purity potassium fluorotantalate

A technology of pure potassium fluorotantalate and potassium fluorotantalate, which is applied in chemical instruments and methods, tantalum compounds, inorganic chemistry, etc., can solve the problem of how to remove impurities such as potassium fluorotantalate and the limited extraction effect of niobium and other impurities. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

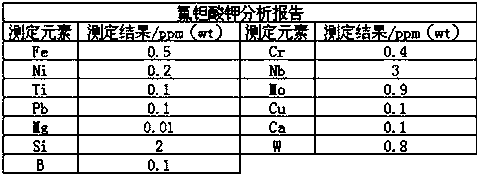

Embodiment 1

[0038] Grind 1000kg of tantalum-niobium ore (30% of tantalum oxide and 20% of niobium oxide) to 200 mesh, add it to 1700L of hydrofluoric acid with a concentration of 55% by mass, and then add 400L of sulfuric acid with a concentration of 92% by mass, and keep it warm break down.

[0039] Enter the ore extraction tank, use MIBK solution to extract tantalum and niobium, make fluorotantalic acid and fluoroniobic acid enter into MIBK, and then use 3.7mol / L sulfuric acid to countercurrent extract in the pickling tank, after extraction, the tantalum and niobium The organic solvent enters the anti-niobium extraction tank, and the sulfuric acid solution with an acidity of 0.75mol / L is used for countercurrent extraction with the organic solvent containing tantalum and niobium. The fluoroniobic acid solution enters the sulfuric acid solution, and the fluorotantalic acid remains in the organic solvent. in solvent.

[0040] The organic solvent containing fluorotantalic acid was put into...

Embodiment 2

[0047] Grinding 1000kg of tantalum-niobium ore (30% of tantalum oxide and 20% of niobium oxide) to below 200 mesh, adding to 1700L of hydrofluoric acid with a mass concentration of 55%, and then adding 400L of sulfuric acid with a mass concentration of 92%, Insulation decomposition.

[0048] Enter the ore extraction tank, use 2-octanol solution to extract tantalum and niobium, fluorotantalic acid and fluoroniobic acid enter the 2-octanol, use 4.2mol / L sulfuric acid to extract countercurrently in the pickling tank, the organic material containing tantalum and niobium The solvent enters the anti-niobium-extracting tantalum tank, and a sulfuric acid solution with an acidity of 0.7 mol / L is used for countercurrent extraction with an organic solvent containing tantalum and niobium.

[0049] Put the fluoroniobic acid solution into the sulfuric acid solution, and the fluorotantalic acid remains in the organic solvent, and the organic solvent containing fluorotantalic acid enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com