Method and device for preparing tantalum powder by stirring sodium and reducing potassium fluotantalate

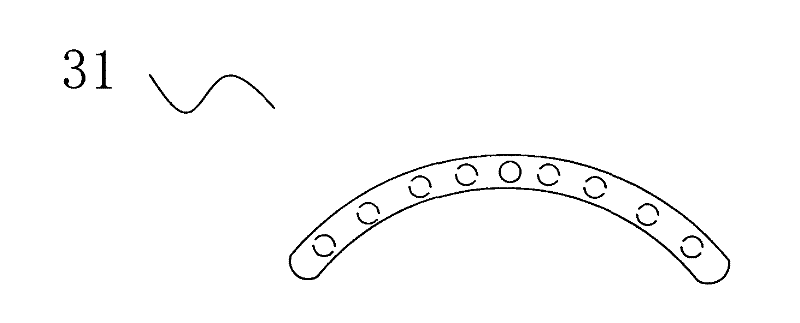

A stirring device and potassium fluorotantalate technology, applied in the field of tantalum powder preparation, can solve the problem of uneven injection of sodium metal and achieve uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

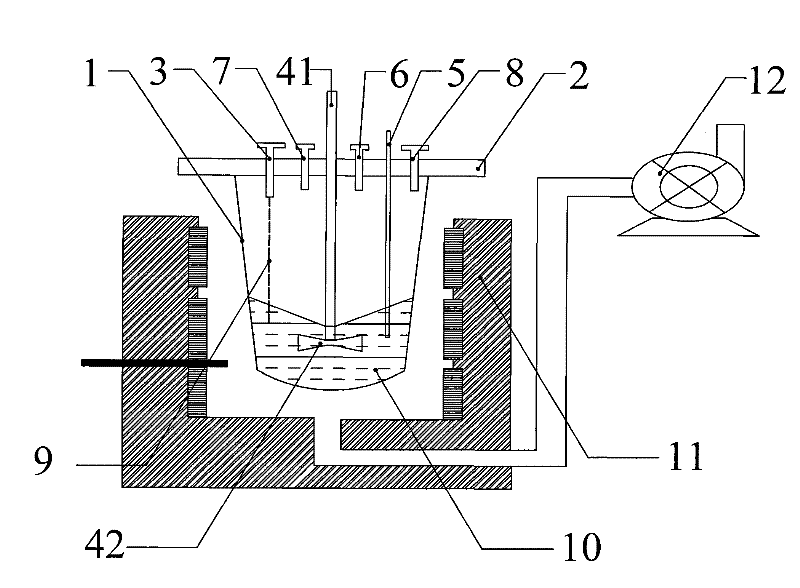

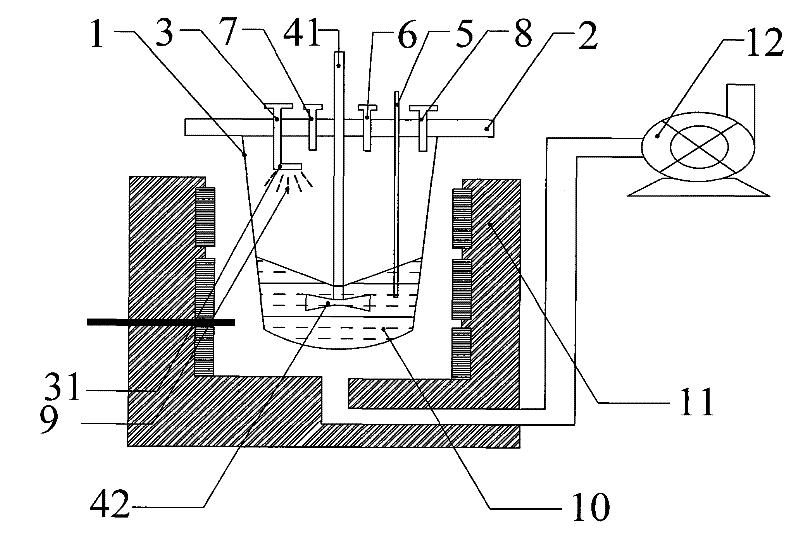

[0052] According to the inventive method, the potassium fluorotantalate of 250kg, the sodium chloride of 100kg are packed into such as figure 2 In the shown reaction device, cover the reaction vessel cover 2 and then seal and evacuate until the pressure is lower than 150 Pa, then fill it with argon, lift the reaction vessel 1 into the electric furnace 11 for heating, and start stirring when the temperature of the material rises to 900°C The device is stirred, and the stirring paddle 42 is lowered into the melt composed of potassium fluorotantalate and potassium chloride, the stirring speed is 80 RPM, and the temperature is kept at 900° C. for 1 hour. Since the reduction of potassium fluorotantalate by sodium is an intense exothermic process, stop the external heating when injecting sodium, and blow air through the blower 12 to cool the reaction vessel, then inject liquid metal sodium into the reaction vessel, and pass the sodium injection speed and cooling. Speed is used to...

Embodiment 2

[0058] According to the inventive method, 80kg sodium chloride, 100kg Repone K, 30kg Potassium Fluoride and a small amount of well-known grain refiner are packed into such as figure 2 In the shown reaction vessel 1, cover the reaction vessel cover 2 and evacuate until the pressure is lower than 150 Pa, then fill it with argon, lift the reaction vessel 1 into the heating furnace 11 for electric heating, when the material rises to 830°C At this time, the stirring paddle is started to stir, and it is lowered into the melt 10, the stirring speed is 100PRM, and it is kept at 830° C. for 1 hour. Add 30KG potassium fluorotantalate, stop heating, inject sodium, and cool reaction vessel 1 by blowing air, and control the temperature to 830°C±10°C through sodium injection speed and cooling speed, so that potassium fluorotantalate-injection sodium is added alternately, every After injecting 25kg of sodium, lift the stirring blade up 4cm, add 90kg of potassium fluorotantalate in total, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com