Method for reducing usage amount of ammonia gas during process of tantalum-niobium hydrometallurgical extraction

A hydrometallurgy and usage-amount technology, applied in the field of non-ferrous metal production, can solve the problems of unclean treatment, large ammonia-containing wastewater, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

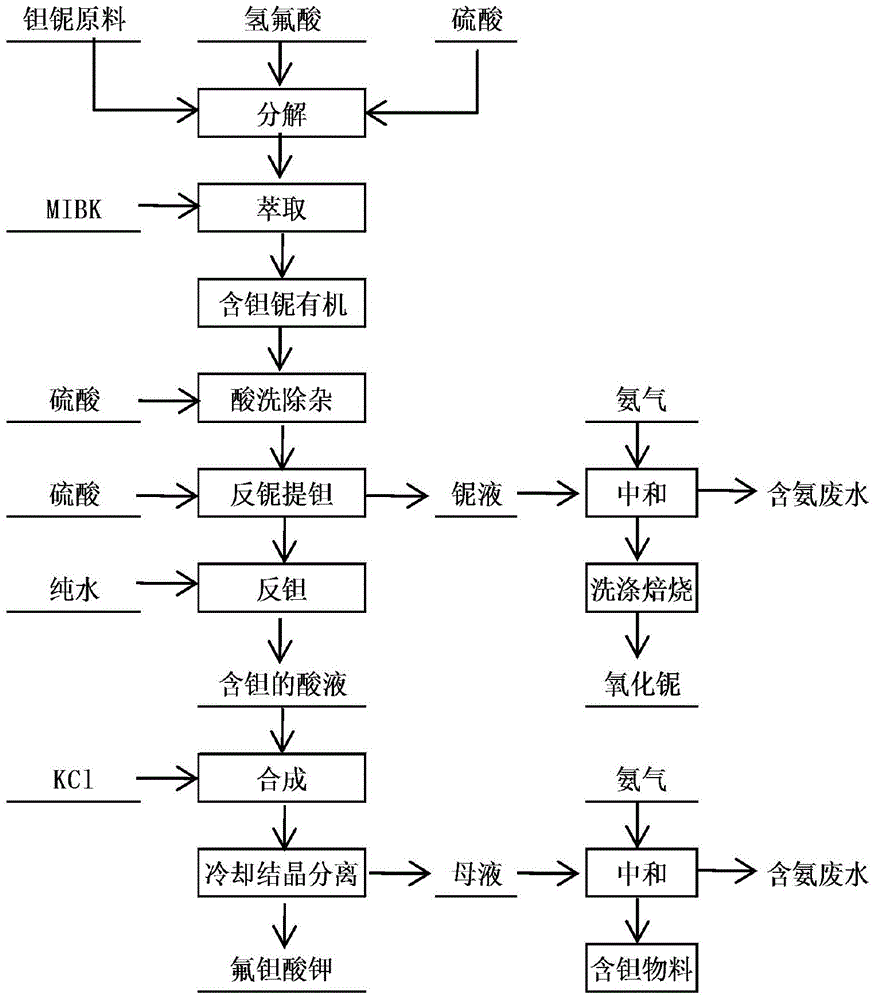

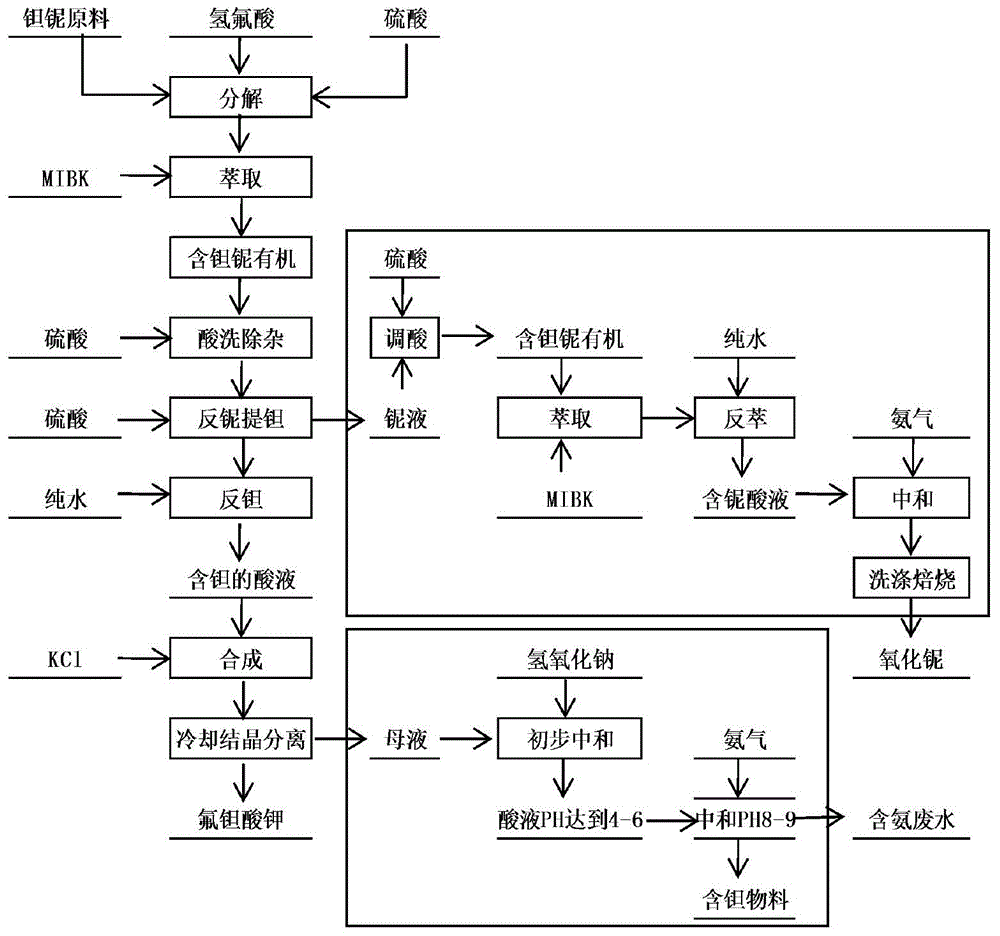

Image

Examples

example 1

[0016] The niobium-containing acid solution (niobium solution) in tantalum-niobium hydrometallurgy is 1000L, its content is: niobium oxide 90g / L, hydrofluoric acid acidity 2.5mol / L, sulfuric acid acidity 0.75mol / L. 190L of 98% concentrated sulfuric acid was added to this solution to adjust the sulfuric acid acidity of the niobium-containing acid solution (niobium solution) to 3.5mol / L. In a countercurrent mixed extraction tank, MIBK is used as the extraction agent, and the flow ratio is O / A equal to 1:1 to extract the acidic solution containing niobium. In the second extraction tank, pure water is used as the stripping agent to back-extract the MIBK containing niobium-containing acid solution, and the flow ratio is controlled so that O / A is equal to 1:1, and 1000L of niobium-containing acid solution is obtained by back-extraction. Yes: niobium oxide 89g / L, hydrofluoric acid acidity 2.4mol / L, sulfuric acid acidity 0mol / L. Then use 50 kg of ammonia gas to precipitate until the ...

example 2

[0020] In the tantalum-niobium hydrometallurgy, the acid solution containing tantalum is 1000L, its content is: tantalum oxide 50g / L, hydrofluoric acid acidity 0.7mol / L, add 40% hydrofluoric acid 70L, potassium chloride 40 to this solution kg, heat preservation at 92 degrees Celsius for 1 hour, then cool to room temperature, filter and crystallize to obtain the potassium fluorotantalate product. At the same time, 1300L of mother liquor with an acidity of 1.5mol / L and a content of tantalum oxide of 1.5g / L was produced, and 62 kg of sodium hydroxide was added to the solution to neutralize to a pH of 5-6, and then 9 kg of ammonia gas was introduced. When the pH value of the solution reaches 8-9, it is filtered and washed to obtain 3200 L of ammonia-containing wastewater, and the content of ammonium nitrogen in the water is 1.68 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com