Dynamic crystallization equipment for potassium fluotantalate

A technology of potassium fluorotantalate and crystallization equipment, which is applied in the field of dynamic crystallization equipment of potassium fluorotantalate, can solve the problems that no one has come up with solutions, increase processes, etc., achieve a large proportion, improve product quality, and heat exchange efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

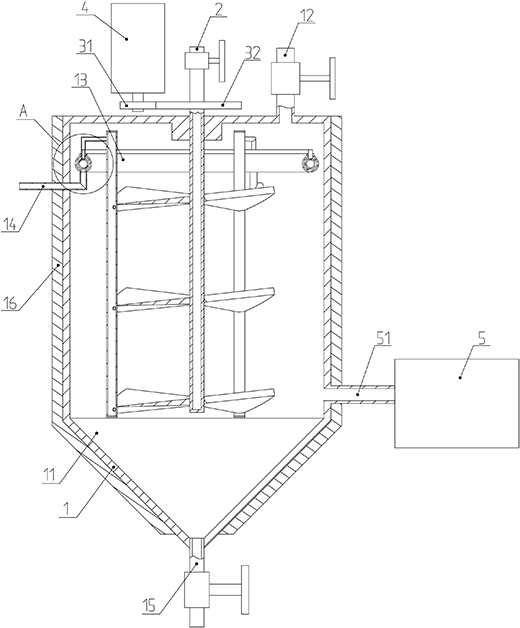

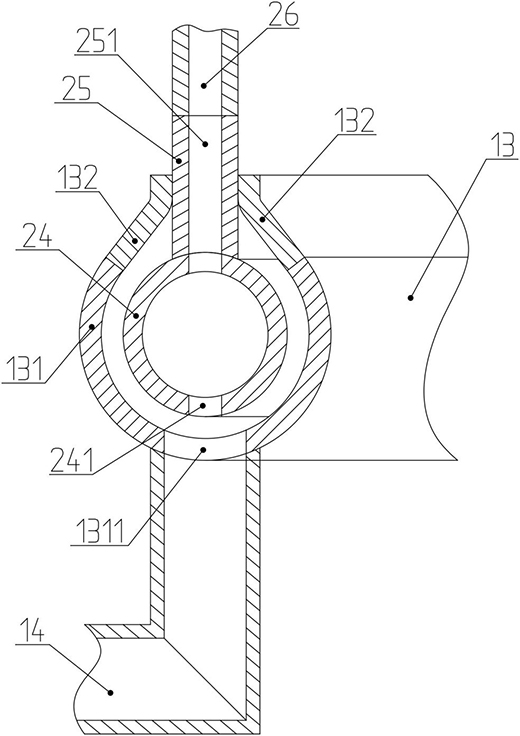

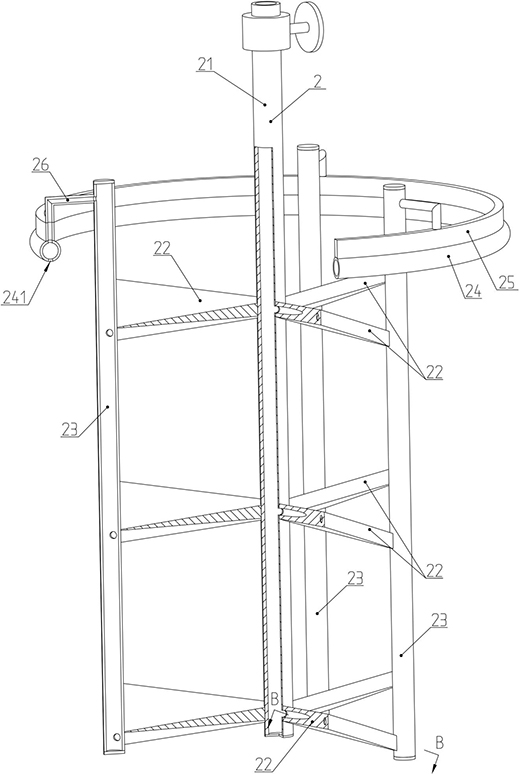

[0033] Embodiment 1, a kind of dynamic crystallization equipment of potassium fluorotantalate, such as Figure 1 to Figure 4 As shown, it includes a tank assembly 1, a stirring blade assembly 2, a pinion 31, a large gear 32 and a motor 4; the tank assembly 1 includes a tank body 11, the tank body 11 is cylindrical, the bottom is funnel-shaped, and the bottom is the discharge material Port 15, a valve is set on the discharge port 15 to control the opening and closing of the discharge port; the top of the tank 11 is provided with a feeding port 12, and the high-temperature concentrated potassium fluorotantalate solution is put in from the feeding port; stirring blade assembly 2 Including a cold medium inlet pipe 21 and a plurality of stirring blades 22, the plurality of stirring blades 22 are fixedly installed on the cold medium inlet pipe 21, and the cold medium inlet pipe 21 is connected with the tank body 11 through a rotating pair; the stirring blades 22 are located in the ta...

Embodiment 2

[0046]Embodiment 2, a dynamic crystallization control method of potassium fluorotantalate, comprising collecting the crystal particle size of potassium fluorotantalate and determining the stirring speed according to the crystal particle size of potassium fluorotantalate; When the particle size of the potassium fluorotantalate is 10-500 μm, the stirring blade assembly 2 is stirred at a speed of 20 rpm; when the potassium fluorotantalate crystal particles are When the particle size is 500-1500μm, the stirring blade assembly 2 is stirred at a speed of 10 rpm; when the crystal particle size of potassium fluorotantalate is 1500-2000 μm, the stirring blade assembly 2 is stirred at a speed of 5 rpm. The potassium crystal particles are precipitated and enriched downward; when the particle size of the potassium fluorotantalate crystal is above 2000 μm, the stirring blade assembly 2 is stirred at a speed of 2 rpm. After the crystallization is completed, the discharge port 15 is opened, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com