Stirring water-washing method and device for producing tantalum powder by reducing potassium fluotantalate via metallic sodium

A technology of potassium fluorotantalate and water washing device, applied in the field of hydrometallurgy, which can solve the problems of increased impedance, reduced reliability, and easy formation of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

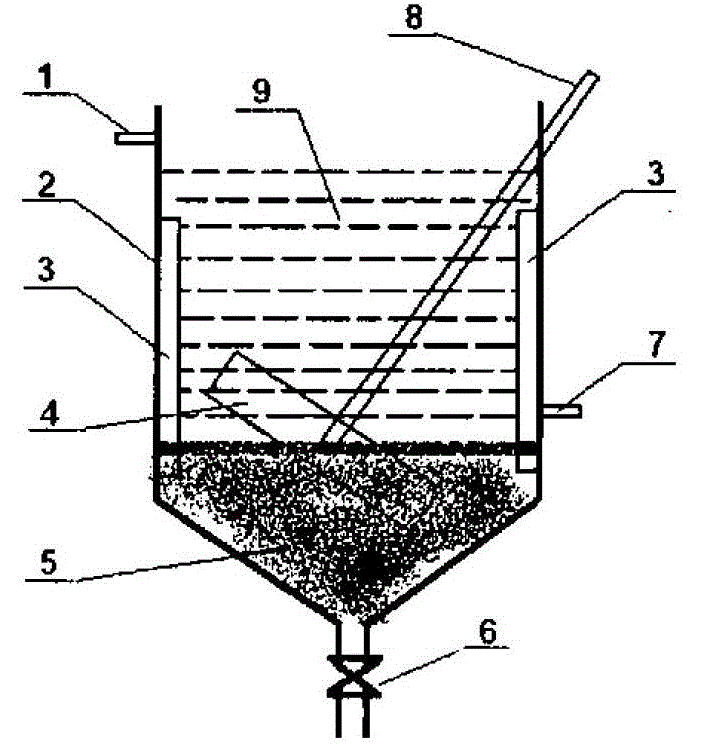

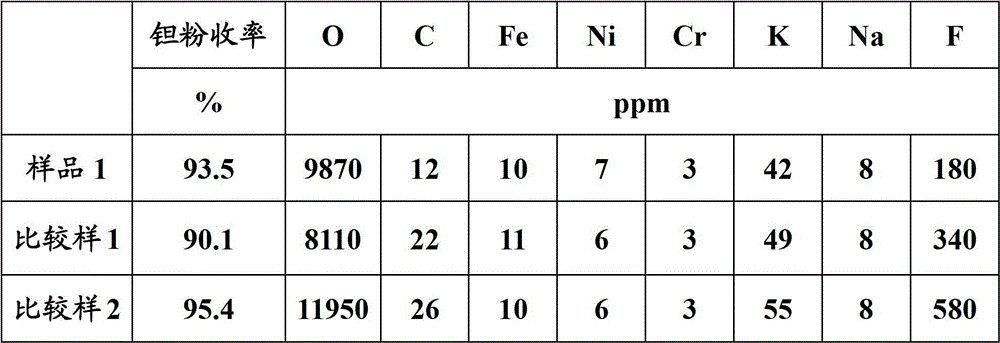

[0040] Put the above sample 1 into such as figure 1 In the stirring water washing tank shown, add deionized water according to the ratio of solid:liquid 1:50, then add 500ml of 4.0mol / L HCl, start the stirring paddle, stir at 120 rpm for 10 minutes, and stop stirring , stand still, after settling for 5 minutes, put the suspension in the upper part of the stirring water washing tank into the recovery tank; repeat this for 10 times, and then transfer to pickling. After pickling, dry and sieve with a 150-mesh sieve. The tantalum powder was analyzed for O, C, K, Na, Fe, Ni, Cr, F according to GB / T 15076.1-15 tantalum and niobium chemical analysis method, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com